All-polymer CPP (cast polypropylene) matt film

A polymer and matte film technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problem of not developing a matting masterbatch, and achieve good flexibility and tear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

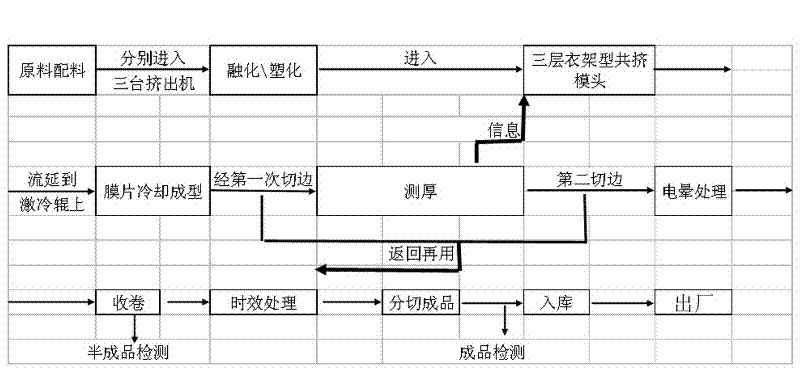

Method used

Image

Examples

Embodiment Construction

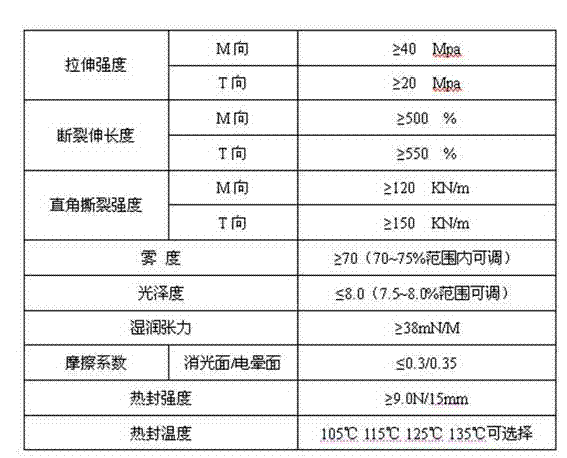

[0015] 1. An all-polymer CPP matting film, prepared by casting A, B, and C three-layer raw materials, wherein A layer is the matting surface layer, B layer is the core layer, and C layer is the bottom layer. It is characterized in that : The weight ratio of the raw material components of each layer is: A layer: 100% all-polymer matting masterbatch; B layer: polypropylene 97~98%, antistatic agent 2.0~3.0%; C layer: polypropylene 95~ 97%, anti-adhesive agent 3.0~5.0%, the thickness of each layer is: A layer: 5~6μm; B layer: 10~25μm; C layer: 4~5μm.

[0016] In this embodiment, the composition of the all-polymer matting masterbatch includes: polypropylene 25-35%; random polypropylene-ethylene copolymer 30-40%; linear low-density polyethylene 30-45%. The antistatic agent is AY088 antistatic agent, and the anti-adhesive agent is AB801 anti-adhesive agent.

[0017] Among them: AB801 anti-adhesive agent and AY088 antistatic agent are common models in this industry, and the products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com