Preparation method of monodisperse smooth surface amorphous titania nanospheres

A smooth surface, titanium dioxide technology, applied in the direction of titanium dioxide, nanotechnology for materials and surface science, titanium oxide/hydroxide, etc. Scientific method, low price, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] In step 1, the titanium nitride powder is dissolved in water at a weight ratio of 0.4:130 and then stirred for 0.5 h; wherein, the water is deionized water to obtain an aqueous solution of titanium nitride. Then add hydrogen peroxide with a concentration of 25% and ammonia with a concentration of 28% to the titanium nitride aqueous solution in turn, and stir for 1 h; wherein, the volume ratio of the titanium nitride aqueous solution, hydrogen peroxide and ammonia is 110.4:18:14, and the precursor is obtained solution.

[0022] In step 2, first mix the precursor solution and ethanol according to the volume ratio of 2:8, and then stir for 0.5 h to obtain a microemulsion solution. Then the microemulsion solution was heated at 60° C. for 20 h to obtain a white precipitate.

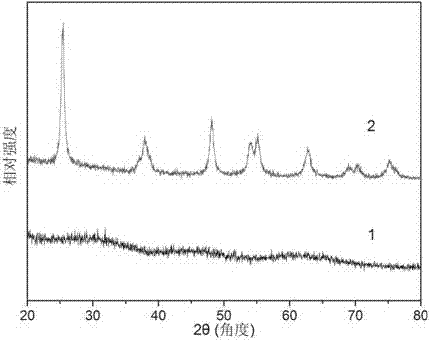

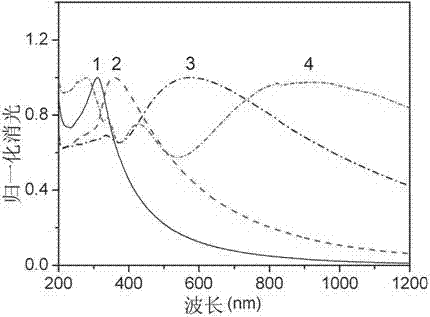

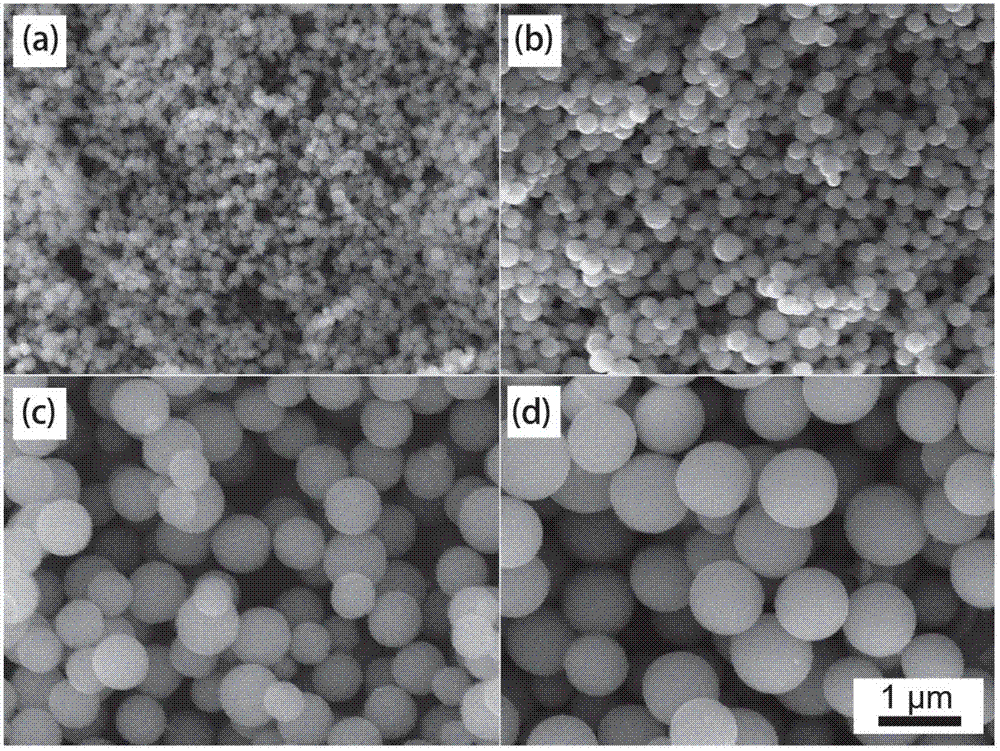

[0023] Step 3, wash the white precipitate with ethanol, and then dry it at 55°C for 28 hours to obtain the following figure 1 d, and as figure 2 and ...

Embodiment 2

[0025] The concrete steps of preparation are:

[0026] Step 1: First, according to the weight ratio of 0.45:125, the titanium nitride powder is dissolved in water and then stirred for 0.6h; wherein, the water is distilled water to obtain a titanium nitride aqueous solution. Then add hydrogen peroxide with a concentration of 28% and ammonia with a concentration of 27% to the titanium nitride aqueous solution in sequence, and stir for 1.5 hours; wherein, the volume ratio of the titanium nitride aqueous solution, hydrogen peroxide and ammonia is 115:17:15, and the precursor body solution.

[0027] In step 2, the precursor solution and ethanol are mixed according to the volume ratio of 3:7, and then stirred for 0.6 h to obtain a microemulsion solution. Then the microemulsion solution was heated at 65° C. for 16 h to obtain a white precipitate.

[0028] Step 3, wash the white precipitate with ethanol, and then dry it at 58°C for 27 hours to obtain the following figure 1 as shown...

Embodiment 3

[0030] The concrete steps of preparation are:

[0031] In step 1, the titanium nitride powder is dissolved in water at a weight ratio of 0.5:120 and then stirred for 0.7 hours; wherein, the water is deionized water to obtain an aqueous solution of titanium nitride. Then add hydrogen peroxide with a concentration of 30% and ammonia with a concentration of 27% to the titanium nitride aqueous solution in turn, and stir for 2 hours; wherein, the volume ratio of the titanium nitride aqueous solution, hydrogen peroxide and ammonia is 120:16:16, and the precursor is obtained solution.

[0032] In step 2, the precursor solution and ethanol are mixed according to the volume ratio of 4:6, and then stirred for 0.7 h to obtain a microemulsion solution. Then the microemulsion solution was heated at 70° C. for 16 h to obtain a white precipitate.

[0033]Step 3, wash the white precipitate with ethanol, and then dry it at 60°C for 26 hours to obtain the following figure 1 as shown in b, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com