Preparation method of matte water-borne wood paint

A water-based wood lacquer and matte technology, applied in the direction of coating, etc., can solve the problems of poor smoothness, high cost and price, and achieve the effects of reducing resin content, convenient coating, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

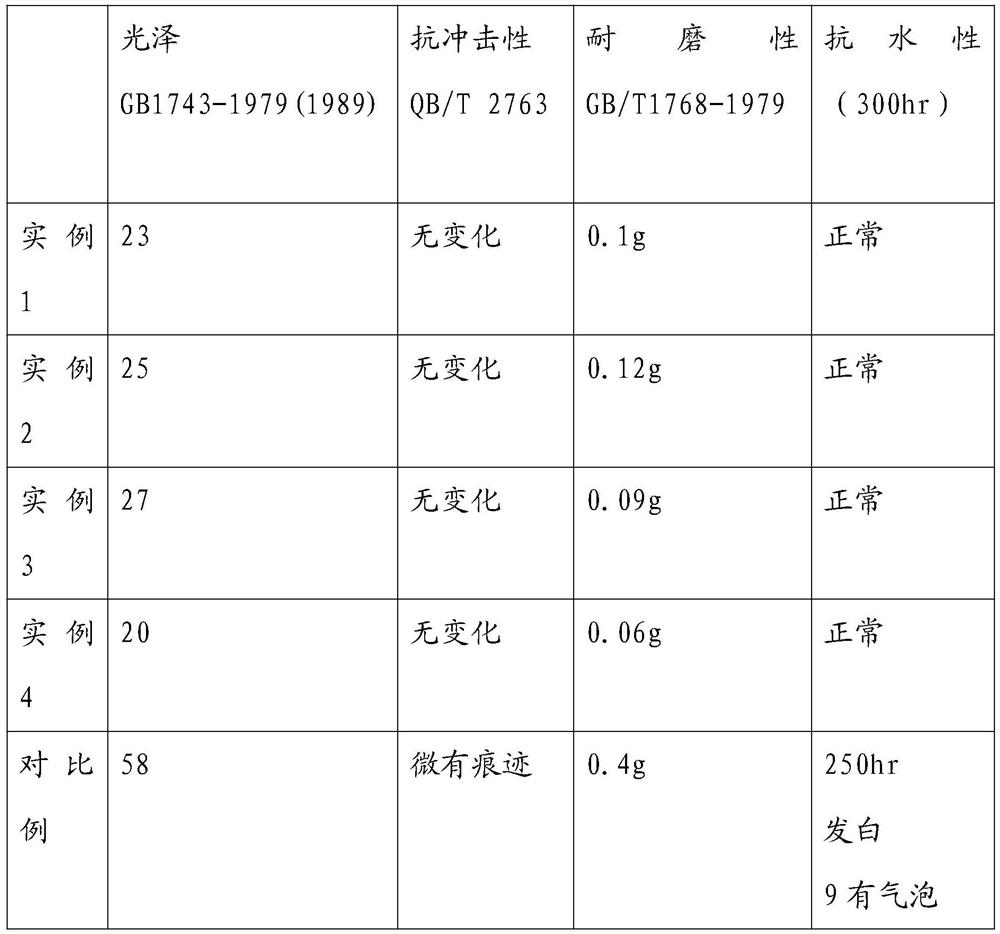

Examples

Embodiment 1

[0030] The embodiment of the present invention provides a method for preparing matte water-based wood lacquer, comprising the following raw materials in parts by weight: 45 parts of modified acrylic resin emulsion, 5 parts of silicon acrylic emulsion, 2 parts of dispersant, 4 parts of leveling agent, thickener 6 parts, 1 part of wax paste, 2 parts of defoamer, 15 parts of pigment, 15 parts of matting powder, 50 parts of deionized water;

[0031] Including the following preparation process:

[0032] Step 1. Put the modified acrylic resin emulsion and silicon-acrylic emulsion into the reaction tank for stirring, and stir evenly;

[0033] Step 2, add pigments to the reaction tank again, and fully stir;

[0034] Step 3, then add dispersant, leveling agent, defoamer, wax paste, thickener to fully stir;

[0035] Step 4, then add the matting powder in equal amounts several times, and fully stir to make the matting agent completely dispersed in the slurry;

[0036] Step 5. Finally,...

Embodiment 2

[0047] The embodiment of the present invention provides a method for preparing matte water-based wood lacquer, comprising the following raw materials in parts by weight: 80 parts of modified acrylic resin emulsion, 15 parts of silicon acrylic emulsion, 3 parts of dispersant, 3 parts of leveling agent, thickener 9 parts, 2 parts of wax paste, 4 parts of defoamer, 25 parts of pigment, 30 parts of matting powder, 30 parts of deionized water;

[0048] Including the following preparation process:

[0049] Step 1. Put the modified acrylic resin emulsion and silicon-acrylic emulsion into the reaction tank for stirring, and stir evenly;

[0050] Step 2, add pigments to the reaction tank again, and fully stir;

[0051] Step 3, then add dispersant, leveling agent, defoamer, wax paste, thickener to fully stir;

[0052] Step 4, then add the matting powder in equal amounts several times, and fully stir to make the matting agent completely dispersed in the slurry;

[0053] Step 5. Finall...

Embodiment 3

[0064]The embodiment of the present invention provides a method for preparing a matte water-based wood lacquer, comprising the following raw materials in parts by weight: 80 parts of modified acrylic resin emulsion, 15 parts of silicon acrylic emulsion, 3 parts of dispersant, 6 parts of leveling agent, thickener 9 parts, 2 parts of wax paste, 4 parts of defoamer, 25 parts of pigment, 30 parts of matting powder, 30 parts of deionized water;

[0065] Including the following preparation process:

[0066] Step 1. Put the modified acrylic resin emulsion and silicon-acrylic emulsion into the reaction tank for stirring, and stir evenly;

[0067] Step 2, add pigments to the reaction tank again, and fully stir;

[0068] Step 3, then add dispersant, leveling agent, defoamer, wax paste, thickener to fully stir;

[0069] Step 4, then add the matting powder in equal amounts several times, and fully stir to make the matting agent completely dispersed in the slurry;

[0070] Step 5. Final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com