Composite microbial fertilizer and low temperature embedding preparation method thereof

A compound microorganism and low-temperature granulation technology, applied in the direction of organic fertilizers, etc., can solve the problems of difficulty in maintaining compatibility ratio and functional complementarity, failure to achieve granulation goals, and reduction of use effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of compound microbial fertilizer, is made up of compound microbial fermented product, embedding agent and adhesive powder, by weight percentage, compound microbial fermented product is 50%, embedding agent is 45%; 5%.

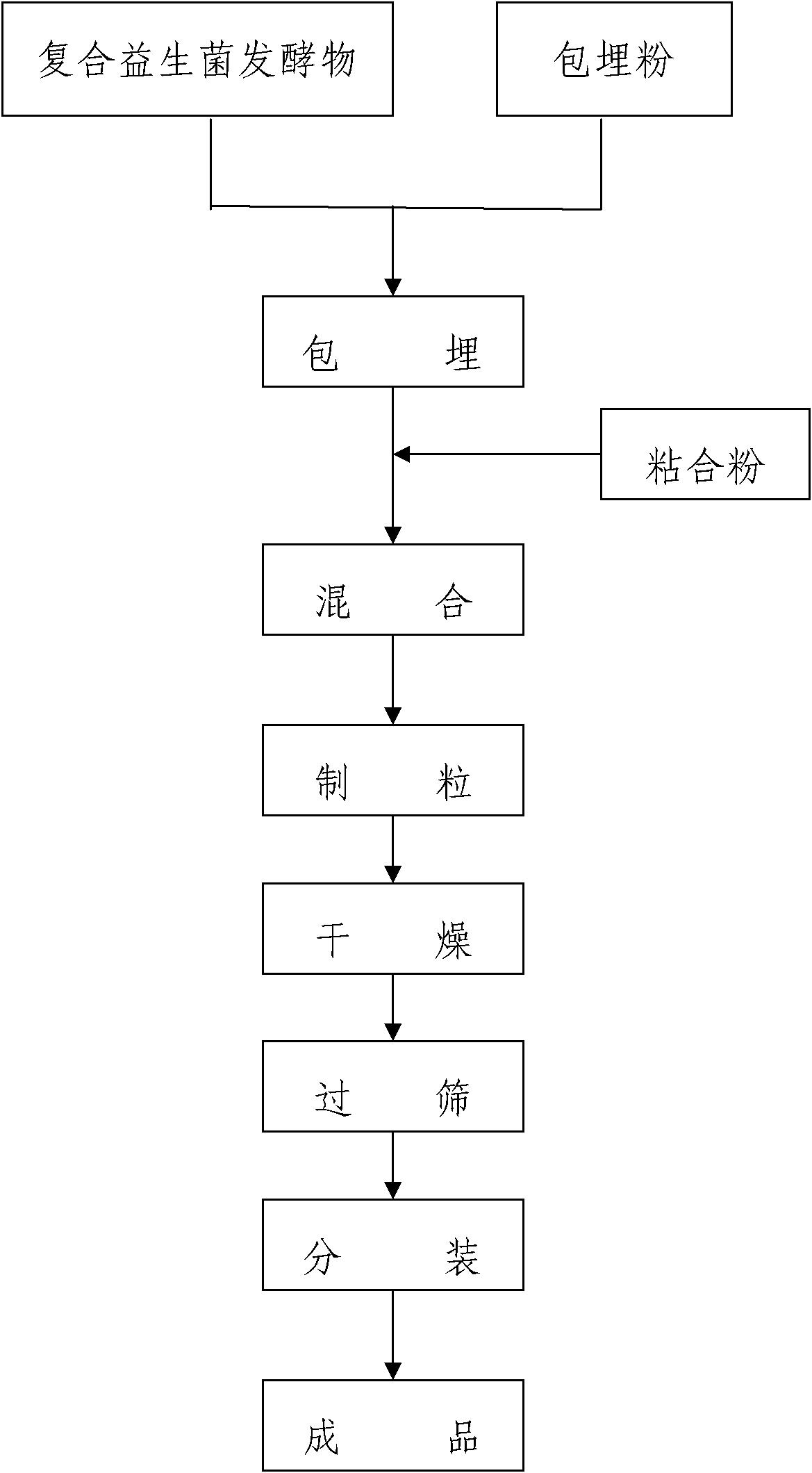

[0020] Preparation:

[0021] 1) Activate and culture Candida utilis, Streptococcus lactis, Lactobacillus acidophilus and Bacillus subtilis respectively according to conventional methods to the logarithmic growth phase, and then the activated Candida utilis, Streptococcus lactis, and Bacillus subtilis Lactobacillus acidiformis and Bacillus subtilis are mixed according to the volume ratio 1:1:1:1, and then the mixed strains are inoculated in the liquid fermentation medium according to 4% by weight for compound culture, and at 30°C, ferment and cultivate for 70h, and ferment The pH value of the substance is 4.5-7.5, until the total number of bacteria reaches more than 109 / mL; the liquid fermentation medium is 2% glucose, 1% peptone, 1% beef extract,...

Embodiment 2

[0042] A kind of compound microbial fertilizer, is made up of compound microbial fermented product, embedding agent and adhesive powder, by weight percentage, compound microbial fermented product is 70%, embedding agent is 25%; 5%.

[0043] Preparation:

[0044] 1) The combined culture of Candida utilis, Streptococcus lactis, Lactobacillus acidophilus, and Bacillus subtilis that were co-fermented until the total number of bacteria reached more than 109 / mL, and the slow-growing cultures that were respectively cultured to the logarithmic growth phase Soybean Rhizobium, Azospirillum lipogenicum, Rhodopseudomonas palustris, Bacillus megaterium, Bacillus colloidus and Azotobacter rufosa are mixed to obtain the fermentation product of complex microorganisms. Bacteria accounted for 10% each.

[0045] 2) Prepare embedding agent, dissolve 2% sodium alginate, 1% starch, and 2% gelatin in water to make a mixed solution, and sterilize under high pressure. The binding flour is wheat glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com