Method for preparing aryl ketone

A technology of aryl ketone and aryl boronic acid, which is applied in the field of catalysis, can solve the problems of complex reaction system, unfavorable practical application, and high price, and achieve the effects of simple post-processing, wide application range, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

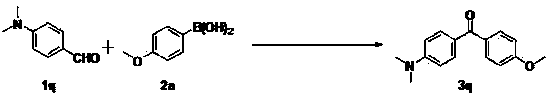

Embodiment 1

[0028]

[0029] [Ru(CO) 3 Cl 2 ] 2 (2.5 mmol%), t-Bu 3 P.HBF 4 (10 mmol %), compound 1a (1 mmol, 106 mg), 2a (2 mmol, 304 mg), K 3 PO 4 .3H 2 O (2 mmol, 532 mg), Toluene (5 mL), H 2 O (0.5 mL), t -BuCOMe (2 mmol, 200 mg). Then the system is heated in an oil bath at 100°C in an argon atmosphere for about 24 hours, the silica gel is adsorbed and the solvent is vacuum spin-dried, and the oxidation product can be obtained by simple column chromatography 3a , the yield is 91%. The following test data confirmed that the target product was obtained; 1 H NMR (CDCl 3 , 400 MHz): δ = 7.83 (d, J = 8.8 Hz, 2H), 7.75 (d, J = 7.5 Hz, 2H), 7.56 (t, J = 7.4 Hz, 1H), 7.46 (t, J = 7.5 Hz, 2H), 6.96 (d, J = 8.8 Hz, 2H), 3.87 (s, 3H): δ = 195.5, 163.1, 138.2, 132.5, 131.8, 130.0, 129.6, 128.1, 113.5, 55.4; MS (C 14 h 12 o 2 ): 212; IR (KBr, cm -1 ): ν 1650.

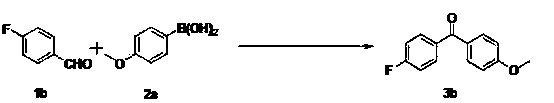

Embodiment 2

[0031]

[0032] [Ru(cymene)Cl 2 ] 2 (2.5 mmol%), Cy 3 P.HBF 4 (10 mmol %), compound 1b (1 mmol, 124 mg), 2a (2 mmol, 304 mg), K 3 PO 4 .3H 2 O (2 mmol, 532 mg), Toluene (5 mL), H 2 O (0.5 mL), t -BuCOMe (2 mmol, 200 mg). Then the system is heated in an oil bath at 100°C in an argon atmosphere for about 24 hours, the silica gel is adsorbed and the solvent is vacuum spin-dried, and the oxidation product can be obtained by simple column chromatography 3b , and the yield was 85%. The following test data confirmed that the target product was obtained; 1 H NMR (CDCl 3 , 400 MHz): δ = 7.81-7.77 (m, 4H), 7.16-7.12 (m, 2H), 6.96 (d, J=8.8, 2H), 3.88 (s, 3H); 13 C NMR (CDCl 3 , 75 MHz): δ = 194.0, 166.2, 163.7, 163.1, 134.3, 134.3, 132.3, 132.2, 132.1, 129.8, 115.3, 115.1 113.5, 55.4; MS (C 14 h 11 FO 2 ): 230; IR (KBr, cm -1 ): ν 1641.

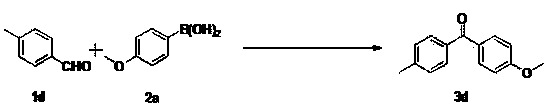

Embodiment 3

[0034]

[0035] The reaction flask was filled with RuH in sequence 2 (CO)PPh 3 (2.5 mmol%), Cy 3 P (10 mmol %), compound 1c (1 mmol, 184 mg), 2a (2 mmol, 304 mg), K 3 PO 4 .3H 2 O (2 mmol, 532 mg), Toluene (5 mL), H 2 O (0.5 mL), t -BuCOMe (2 mmol, 200 mg). Then the system is heated in an oil bath at 100°C in an argon atmosphere for about 24 hours, the silica gel is adsorbed and the solvent is vacuum spin-dried, and the oxidation product can be obtained by simple column chromatography 3c , and the yield was 82%. The following test data confirmed that the target product was obtained; 1 H NMR (CDCl 3 , 400 MHz): δ = 7.79 (d, J=8.5, 1H), 7.62 (s, 1H), 6.96 (d, J=8.5, 1H), 3.89 (s, 3H); 13 C NMR (CDCl 3 , 100 MHz): δ = 194.3, 163.3, 136.9, 132.4, 131.4, 131.2, 129.6, 126.8, 113.6, 55.5; MS (C 14 h 11 BrO 2 ): 290, 294; IR (KBr, cm -1 ): ν 1639.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com