Planetary gear mechanism and mechanical speed changer comprising same

A technology of mechanical transmission and planetary gear, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of difficult layout, low processing efficiency, complex transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

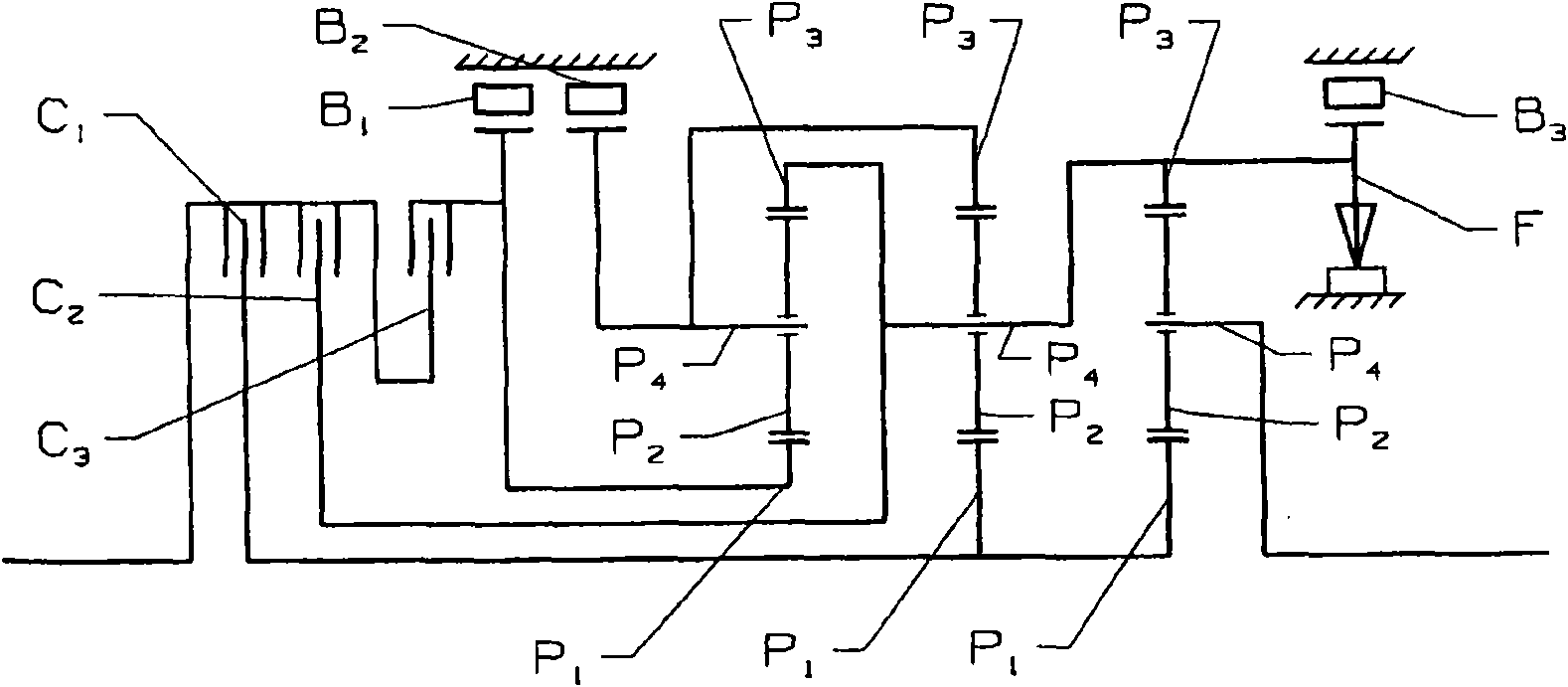

[0053] Figure 3a A schematic diagram showing the basic structure of an embodiment of the mechanical transmission of the present invention, which includes a planetary gear mechanism A, a housing C, and also includes the related components that can realize the planetary gear mechanism A and the housing C. Relatively rotating braking mechanism, that is, a braking mechanism installed between the planet carrier assembly 4 and the housing C to realize no relative rotation between the planet carrier assembly 4 and the housing C, is called For the planetary carrier brake mechanism B C . The planetary gear mechanism A includes an input sun gear assembly 1, an output sun gear assembly 3, two planetary gear assemblies 2 arranged around the input sun gear assembly 1 and the output sun gear assembly 3, and a planet carrier assembly 4 and locking mechanism 5. Here, three or another number (such as one or four) of planetary gear assemblies 2 can also be provided, preferably evenly spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com