Welding seam measuring method based on micro field depth

A measurement method and local technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of not being able to stably and reliably extract the center position of the weld seam and the width of the seam gap, the detection failure of the seam center and width, Geometric features cannot be fully represented, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] First introduce the related concepts:

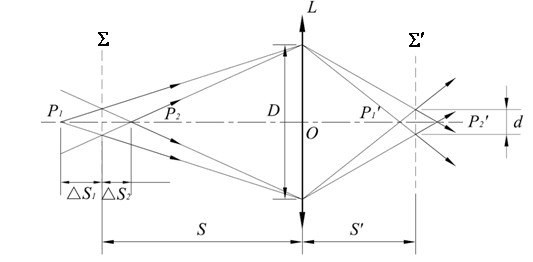

[0027] After the camera is focused, it can form a clear image in the range before and after the focus. This range is called the depth of field. For general household cameras, the larger the depth of field, the better. For example, for a lens with a focal length of 35mm, when the shooting distance is about 3m, the depth of field is about 0.21m, and if the shooting distance is 10m, the depth of field is infinite. When the shooting distance is 50mm, the depth of field is about 3mm; when the shooting distance is 15mm, the depth of field is about 0.017mm, and the optical magnification at this time is 2 times. In general, the greater the optical magnification, the smaller the depth of field. Therefore, in the present invention, the depth of field formed when the optical magnification is greater than 2 times is called a micro depth of field. Compared with the lens, the micro depth of field is located in a specific space area in front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com