Capacitance tomography sensor with powder dielectric coefficient variation measurement electrode

A technology of capacitance tomography and measuring electrodes, which is applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve the problem of not setting the dielectric coefficient change measuring electrodes of materials, etc., to correct errors and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

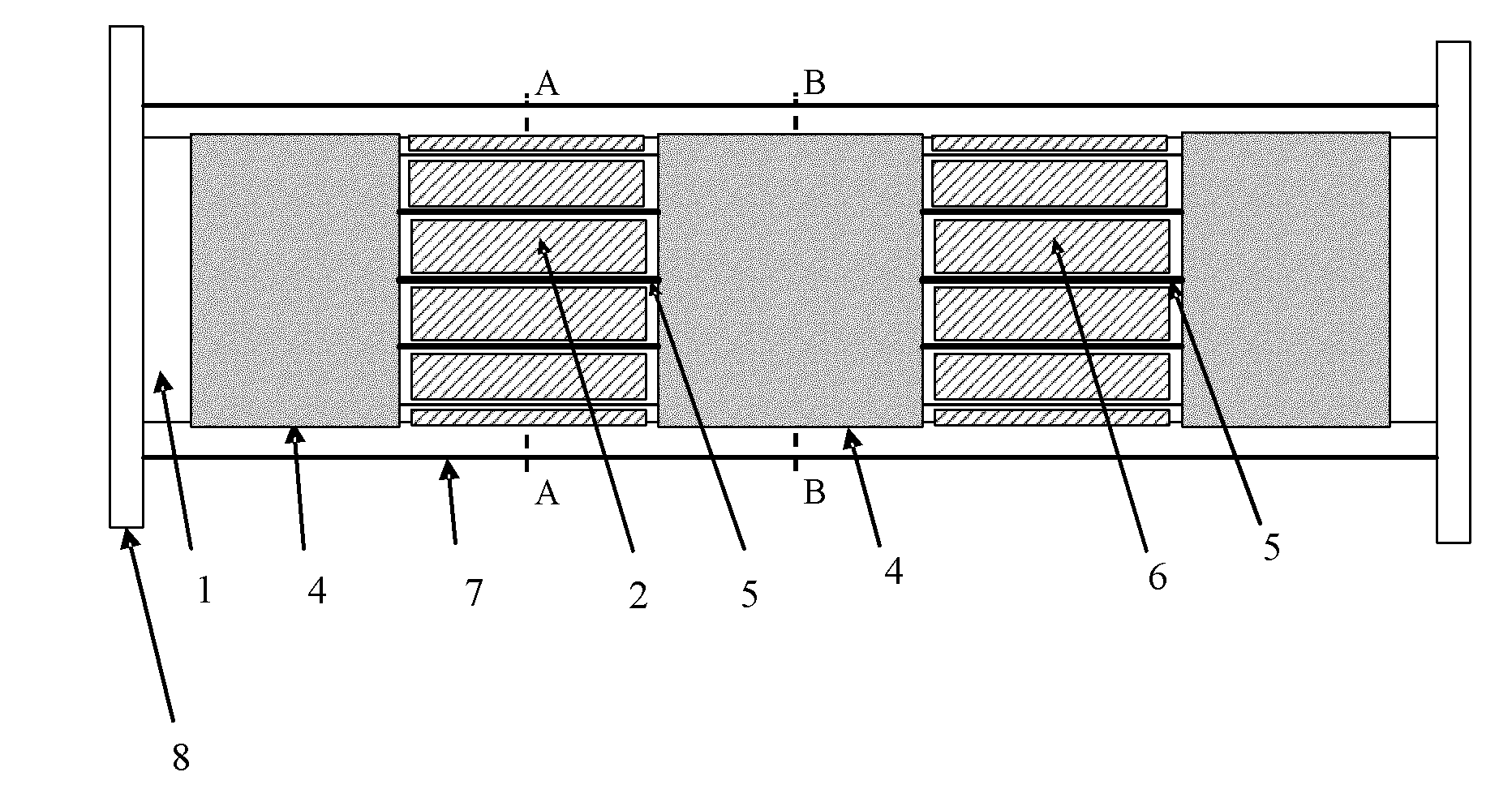

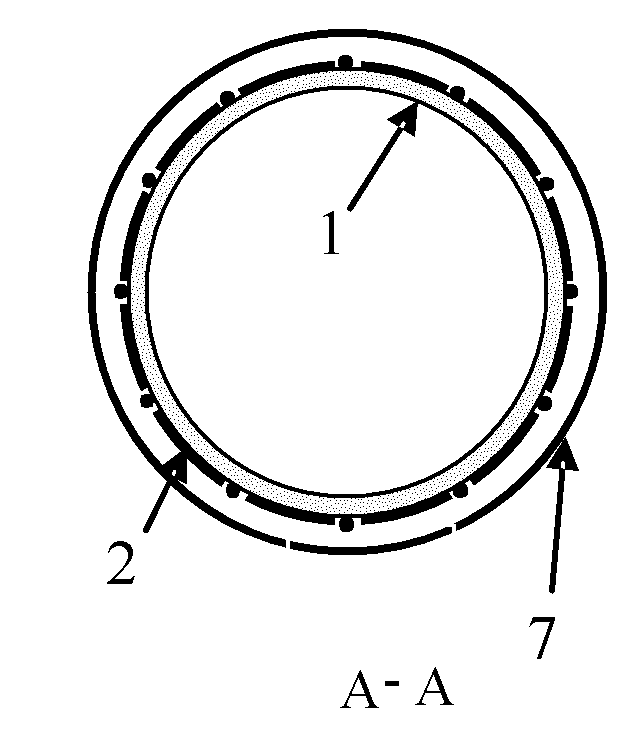

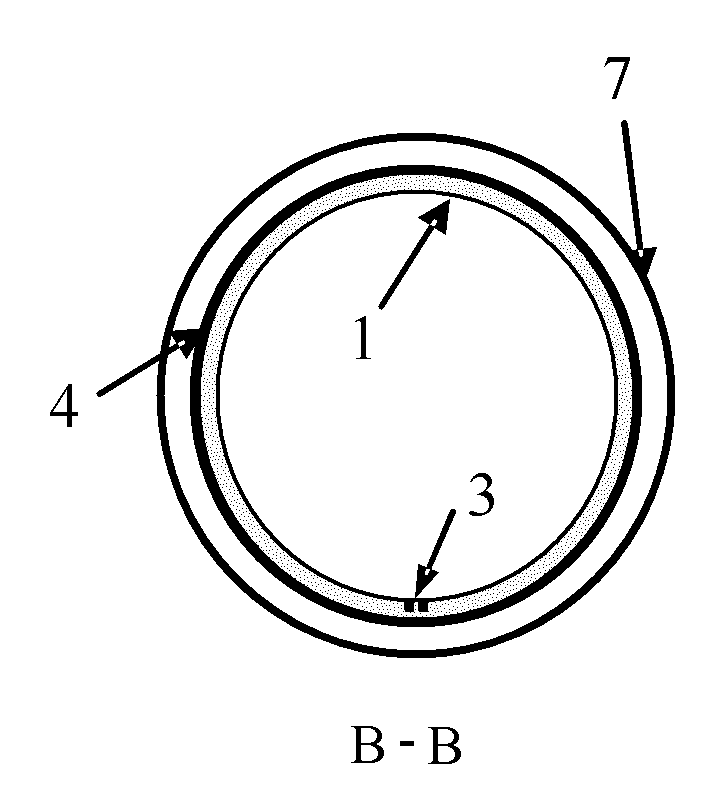

[0028] The present invention provides an electrical capacitance tomography sensor with an electrode for measuring the change in dielectric coefficient of powder or grain. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] As shown in Figure 1, the sensor includes a sensor inner frame 1, two sets of particle distribution measurement electrode arrays, electrode end shielding electrodes 4, inter-electrode shielding electrodes 5, sensor outer shielding frame 7, and flanges 8 connected to the front and rear pipelines , the first group of electrode array signal transmission cables for powder particle distribution measurement 9, the second group of powder particle distribution measurement electrode array signal transmission cables 11, ECT signal acquisition equipment and connecting ground wires. The sensor also has one or more sets of dielectric coefficient change measuring electrode groups 3 for measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com