Woven fiber core overhead wire

A technology of braided fibers and overhead wires, applied in the direction of conductors, non-insulated conductors, power cables, etc., can solve the problems of enlarged damage, major equipment accidents of disconnection, personal casualties, etc., and achieve enhanced longitudinal tensile strength and improved lateral Effects of bending and crash resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

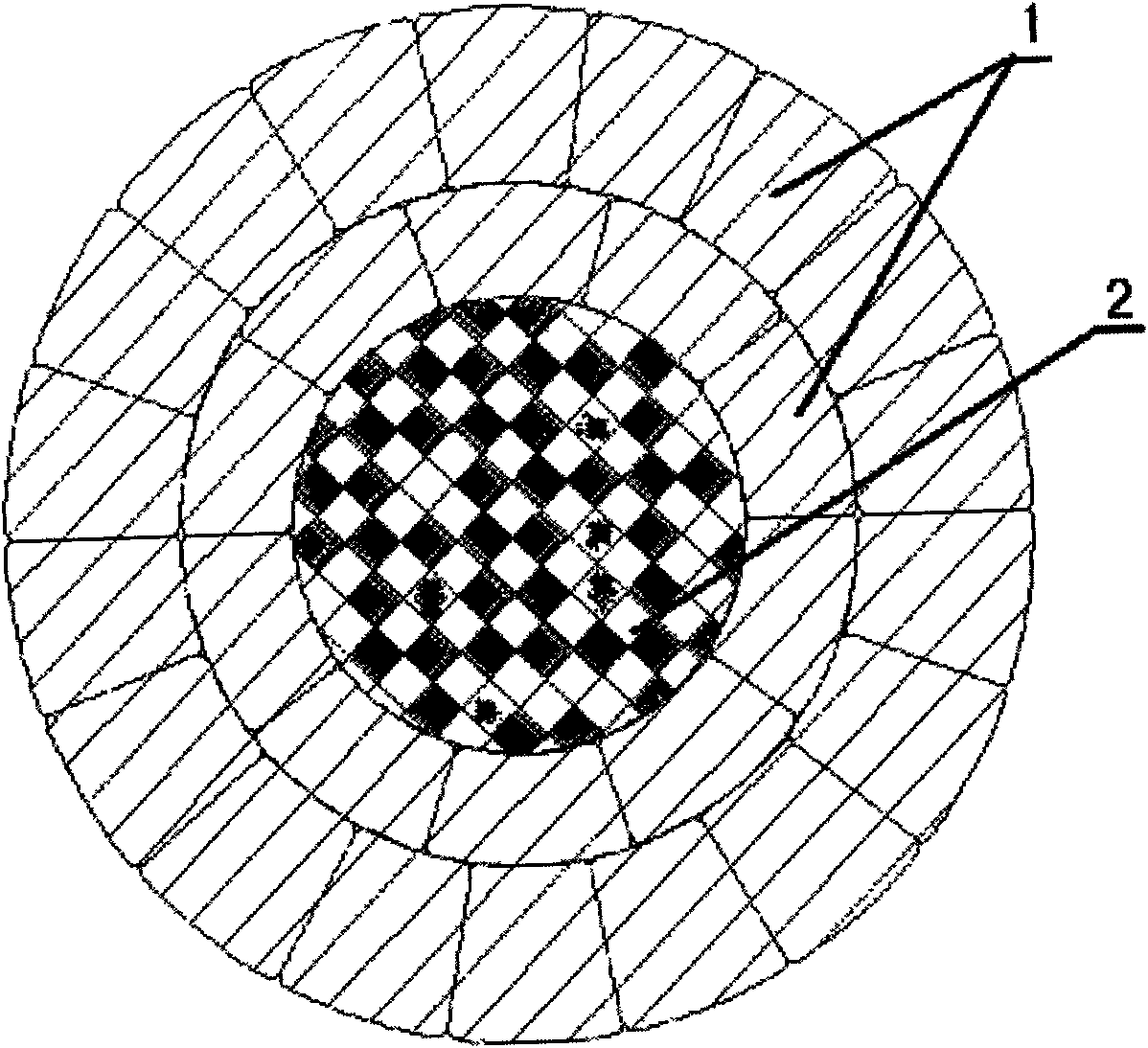

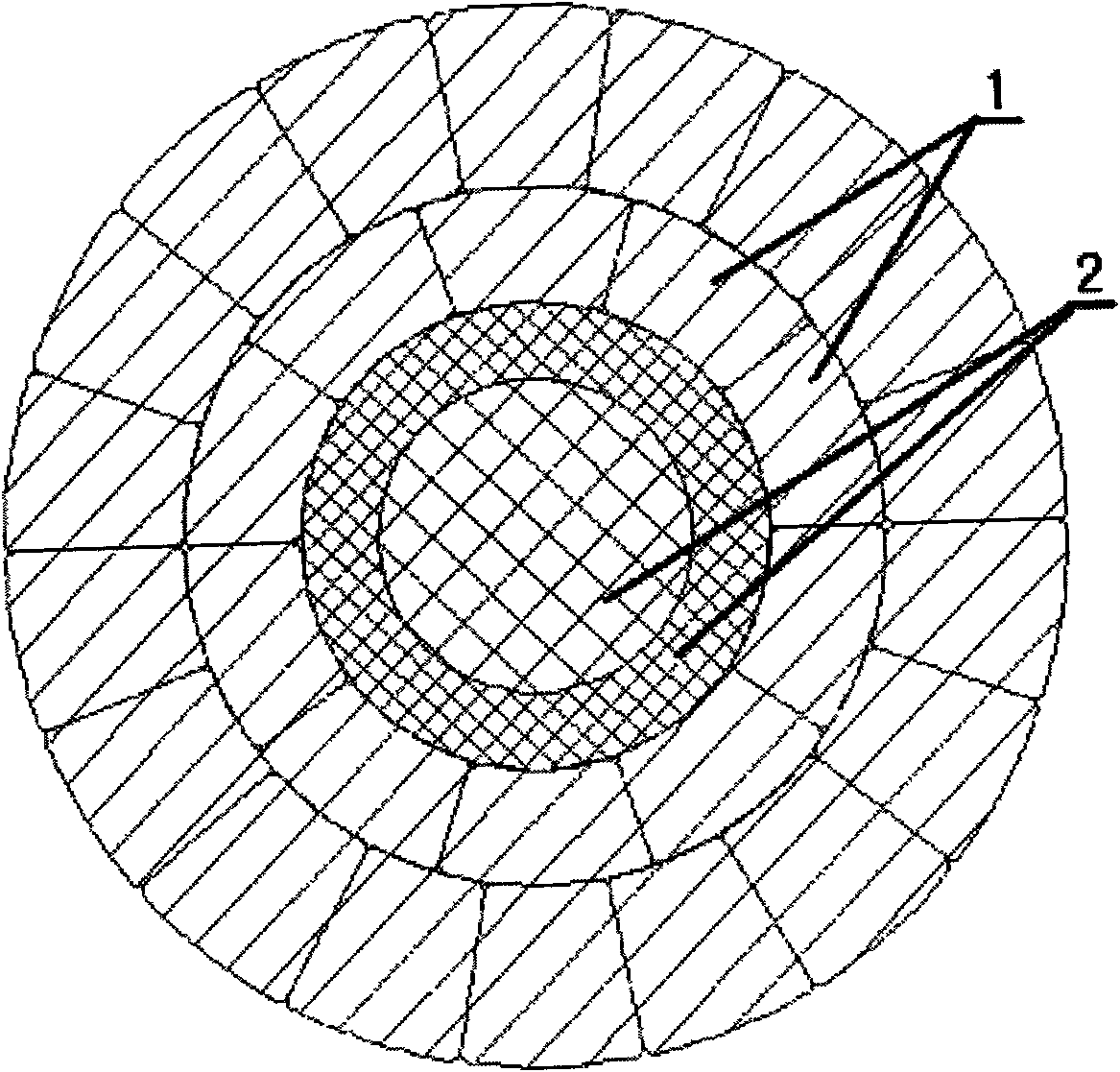

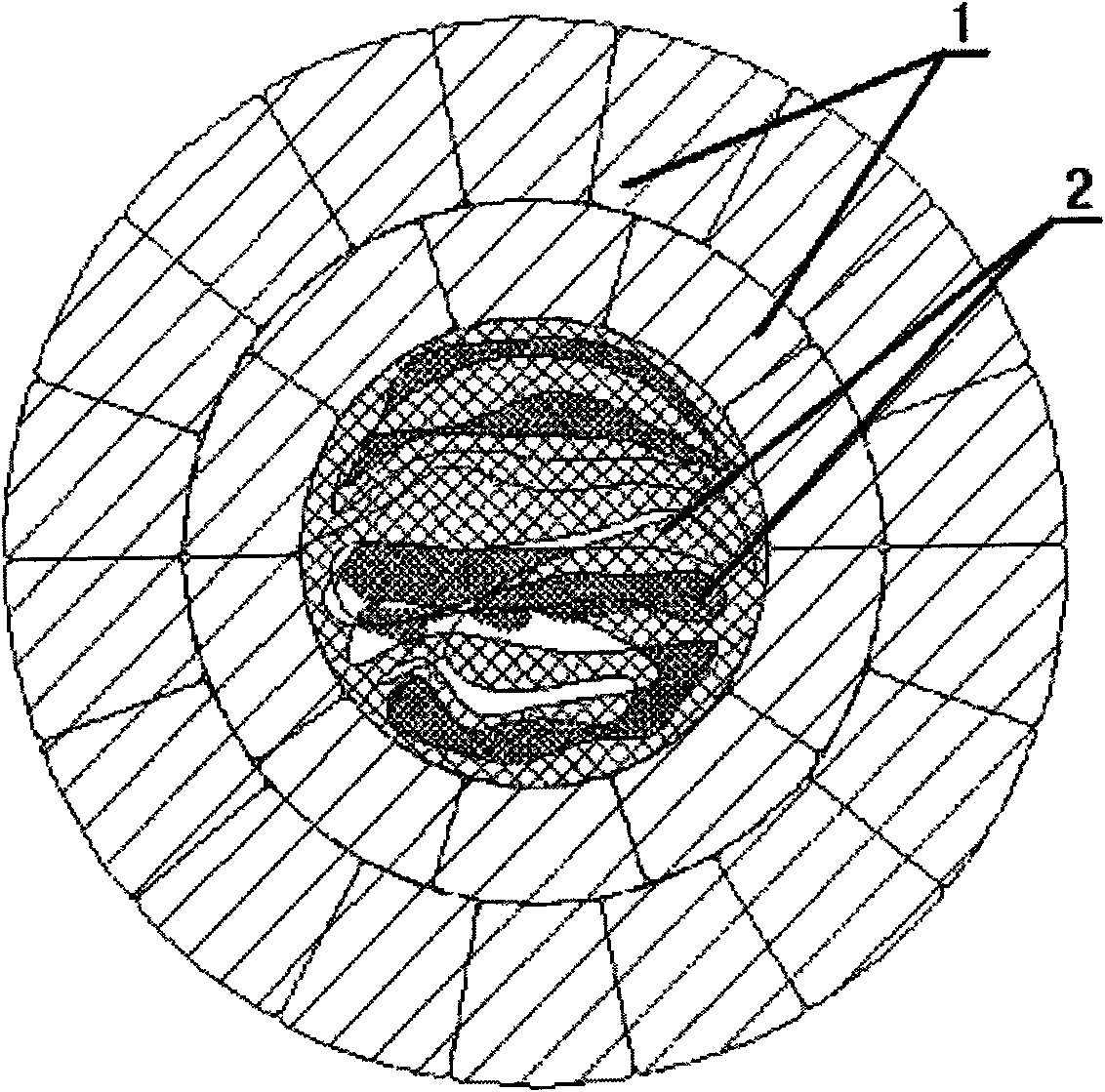

[0013] Two or more kinds of fibers are braided in 2D or 3D to form a rod-shaped braided fiber core 2, which is used as the carrying core of the wire, and there is a twisted conductor 1 outside the braided fiber core.

[0014] The braided fiber core 2 can be a hybrid braided structure, a concentric circular braided structure, a laminated braided structure, or a spiral braided structure.

[0015] The braided fiber core 2 can also be a resin-impregnated structure as required to improve physical and chemical properties.

[0016] The braided fiber core 2 is used to enhance the longitudinal tensile strength of the wire, improve the lateral bending and impact resistance of the wire, and the conductor 1 is used to conduct current and transmit power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com