Marine power communication compound cable

A composite cable and power technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor cable bending and longitudinal breaking force, low service life, and large space occupation, so as to increase the longitudinal tensile capacity, eliminate the The effect of electromagnetic coupling and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

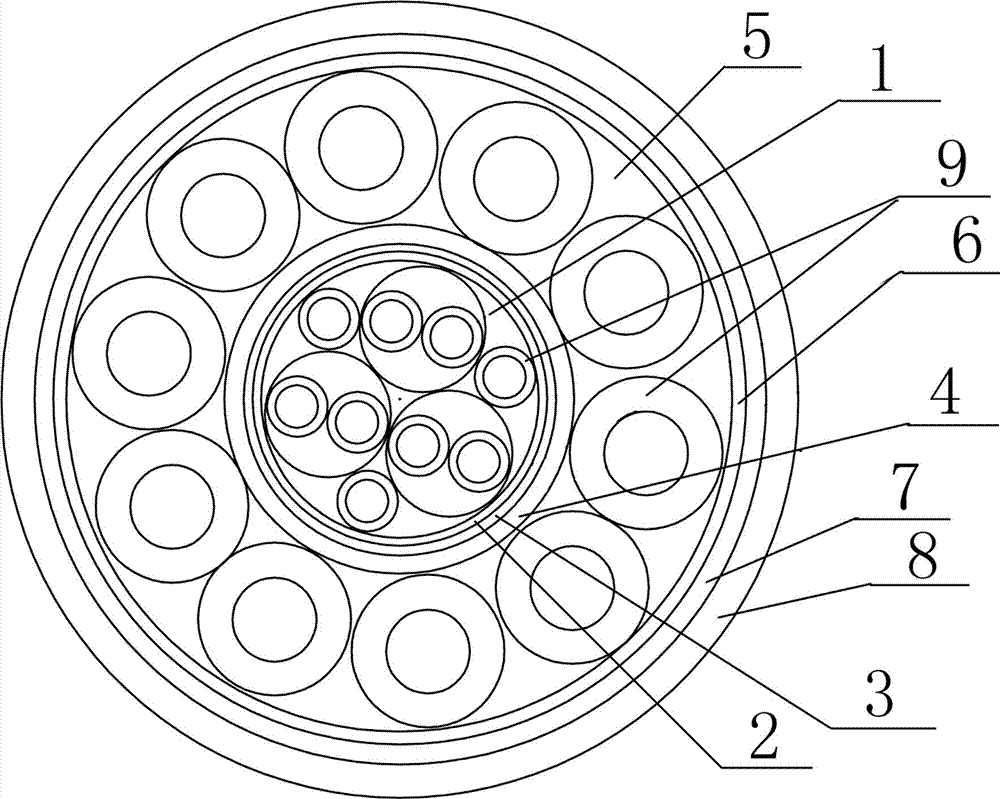

[0016] Such as figure 1 Shown is a marine power communication composite cable, including a communication core conductor layer 1, characterized in that: the communication core conductor layer 1 is sequentially wrapped with a first polyester tape 2, a first shielding layer 3, an inner sheath 4, The power core conductor layer 5, the second polyester tape 6, the second shielding layer 7, and the outer protective layer 8. The communication core conductor layer 1 is composed of several communication core conductors wrapped with insulating materials. The power core conductor layer 5 is composed of several power core conductors wrapped with insulating materials. The insulation material is low-density polyethylene. The first shielding layer 3 is a shielding layer braided by copper wires. The material of the inner protective layer 4 and the outer protective layer 8 is high density polyethylene. The second shielding layer 7 is a shielding layer braided by steel wires.

[0017] The powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com