Frame earth stud of solar photovoltaic module capable of eliminating oxide layer

A solar photovoltaic and grounding bolt technology, applied in the direction of screws, nuts, connecting components, etc., can solve the problems of high contact resistance, fire, breakdown of photovoltaic cells, etc., and achieve the effect of low contact resistance, high mechanical strength and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

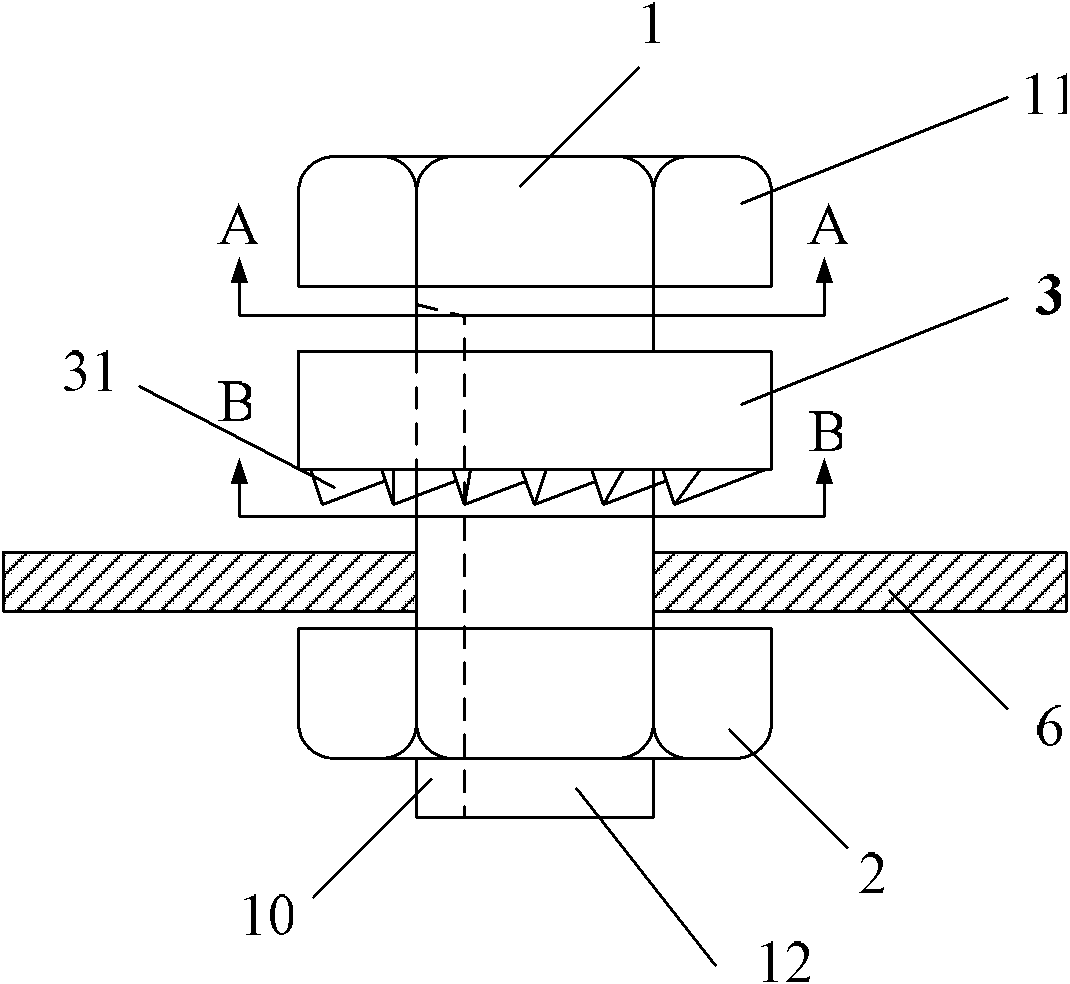

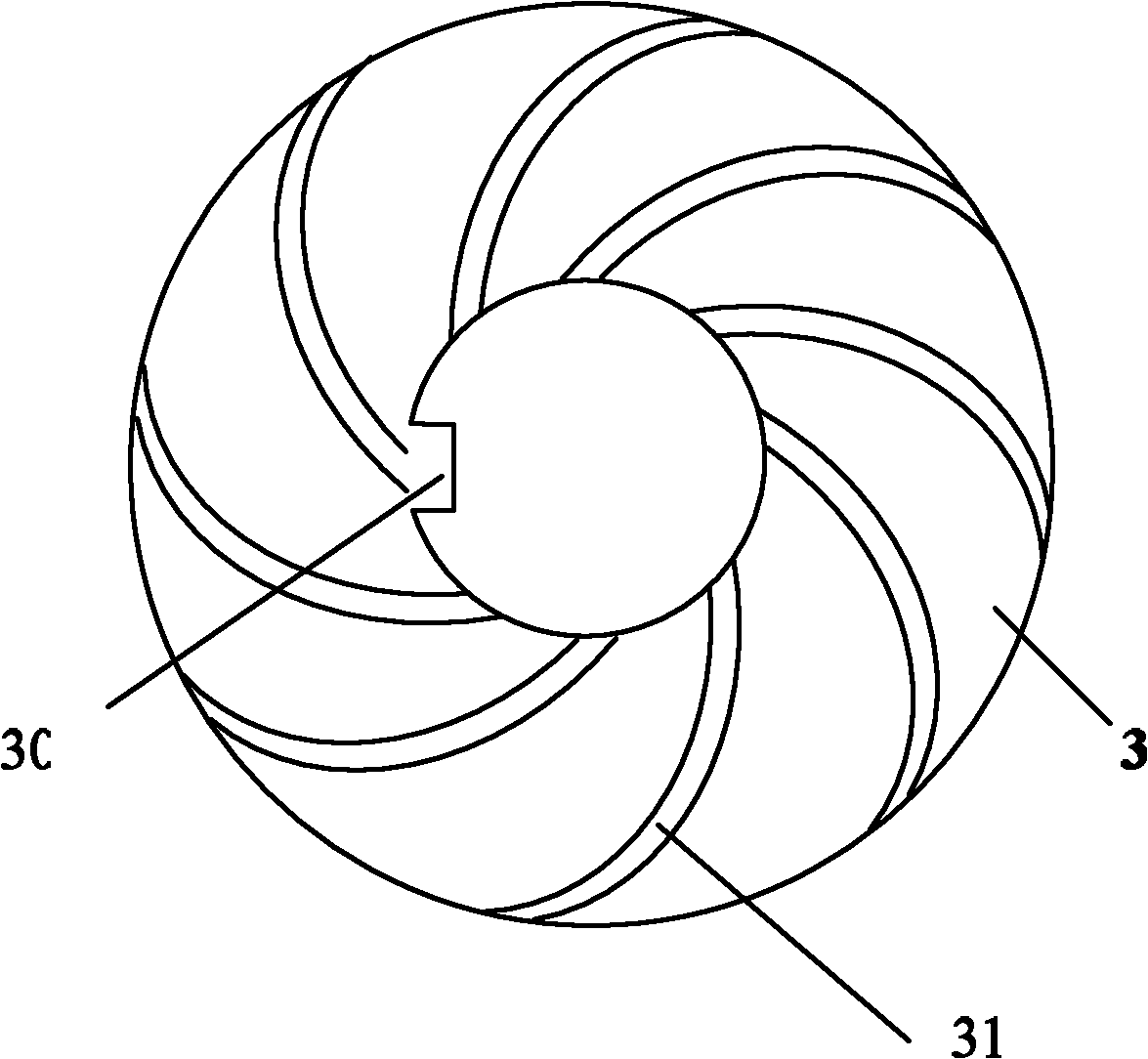

[0025] The invention provides a solar photovoltaic module frame grounding bolt capable of removing the oxide layer, such as figure 1 As shown, the frame ground bolt of the solar photovoltaic module includes a stud 1 , a nut 2 and a scraper 3 .

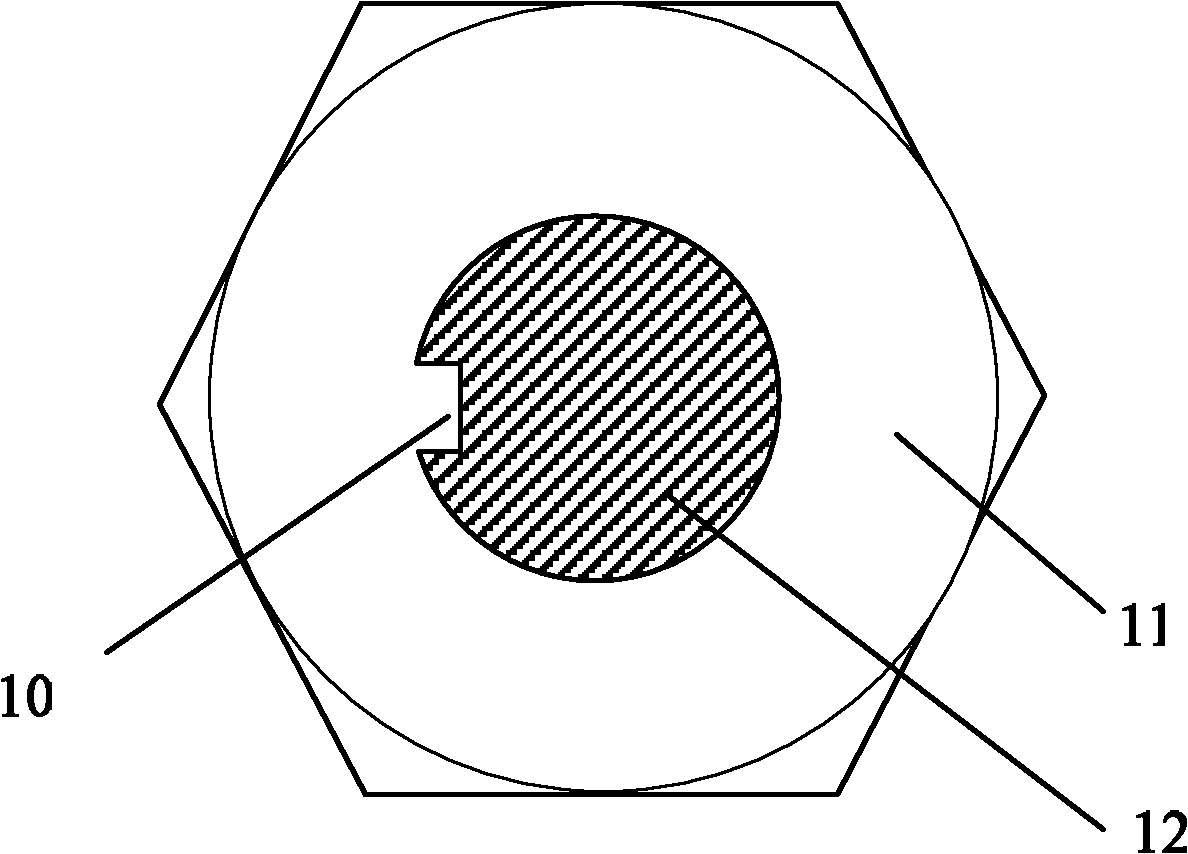

[0026] see figure 2 , The stud 1 includes a stud head 11 and a screw 12, the cylindrical surface of the screw 12 has at least one groove 10 extending along its axial direction. Stud head 11 can be hexagonal stud head, also can be the stud head etc. of circular band slot or Phillips screwdriver groove.

[0027] The nut 2 is screwed on the end of the screw rod 12 away from the stud head 11; when the ground wire is installed, the nut 2 and the stud head 11 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com