Manufacturing method and trimming die for primary iron core disk of long primary linear electric motor

A technology of linear motor and manufacturing method, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of high processing cost of numerical control equipment, difficult to guarantee product quality, and the need for high-power equipment, so as to overcome the problems of product quality. The effect of one-to-one is difficult to guarantee, high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

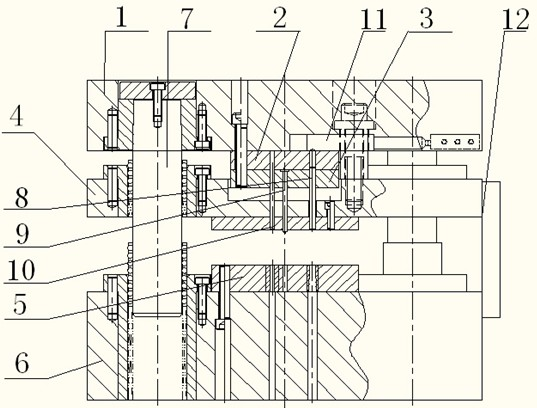

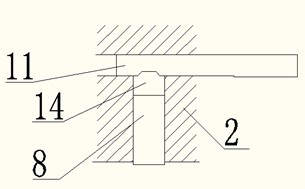

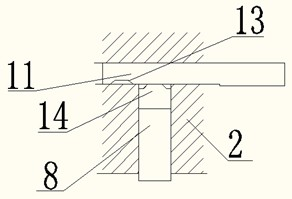

[0015] attached figure 1 A schematic diagram of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to a method for manufacturing the primary iron core sheet of a long primary linear motor, which adopts the continuous automatic punching method of punching grooves, and multi-slots the primary iron core sheet of the long primary linear motor. Placed on a high-speed punching machine, the punching process is completed by multiple continuous automatic punching of the mold on the high-speed punching machine; and each punching machine movement cycle of the stamping die on the high-speed punching machine only completes the punching of 1-2 opening embedding grooves, and punches at the same time 1-2 sets of guide holes or other cavities; all opening embedding grooves and guide holes or other cavitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com