Load balancing control system coaxially operating with dual-direct-current (DC) separately excited machine and control method thereof

A load balancing and control system technology, applied in the direction of motor starters, motor generators/starters, etc., can solve damage to motors or DC speed control devices, ignition of brushes or commutators, armature current deviation, etc. problem, to achieve the effect of obvious practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

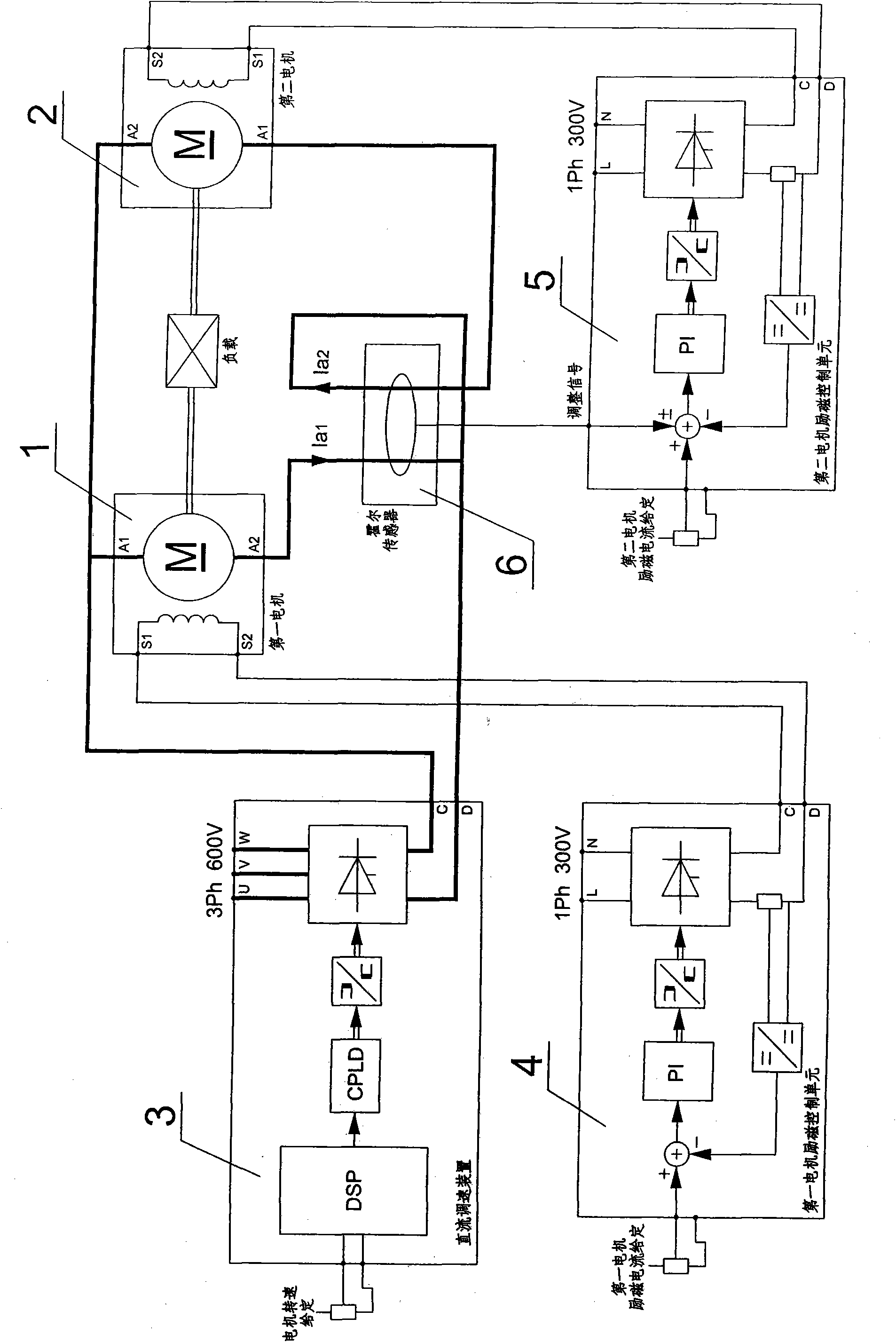

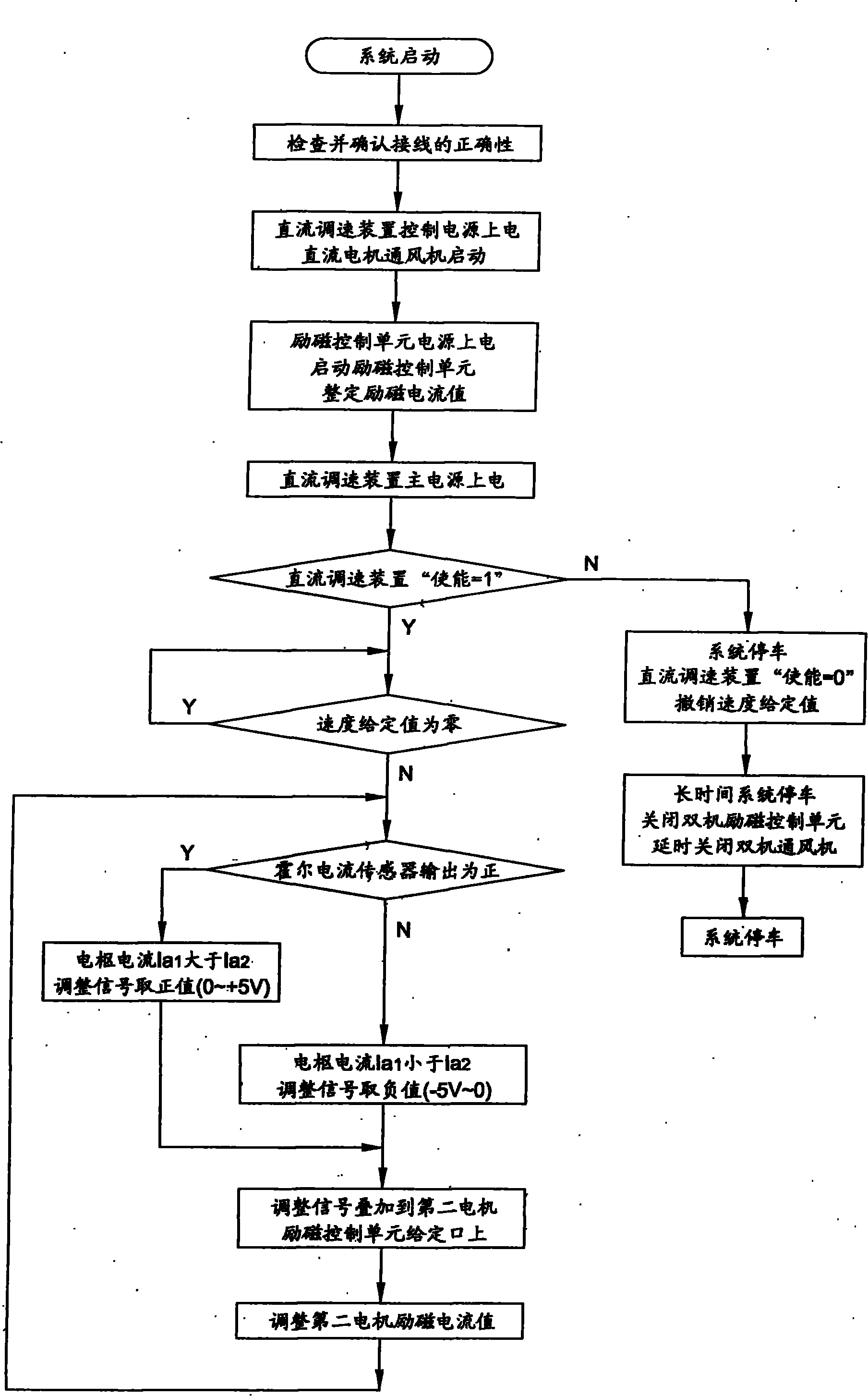

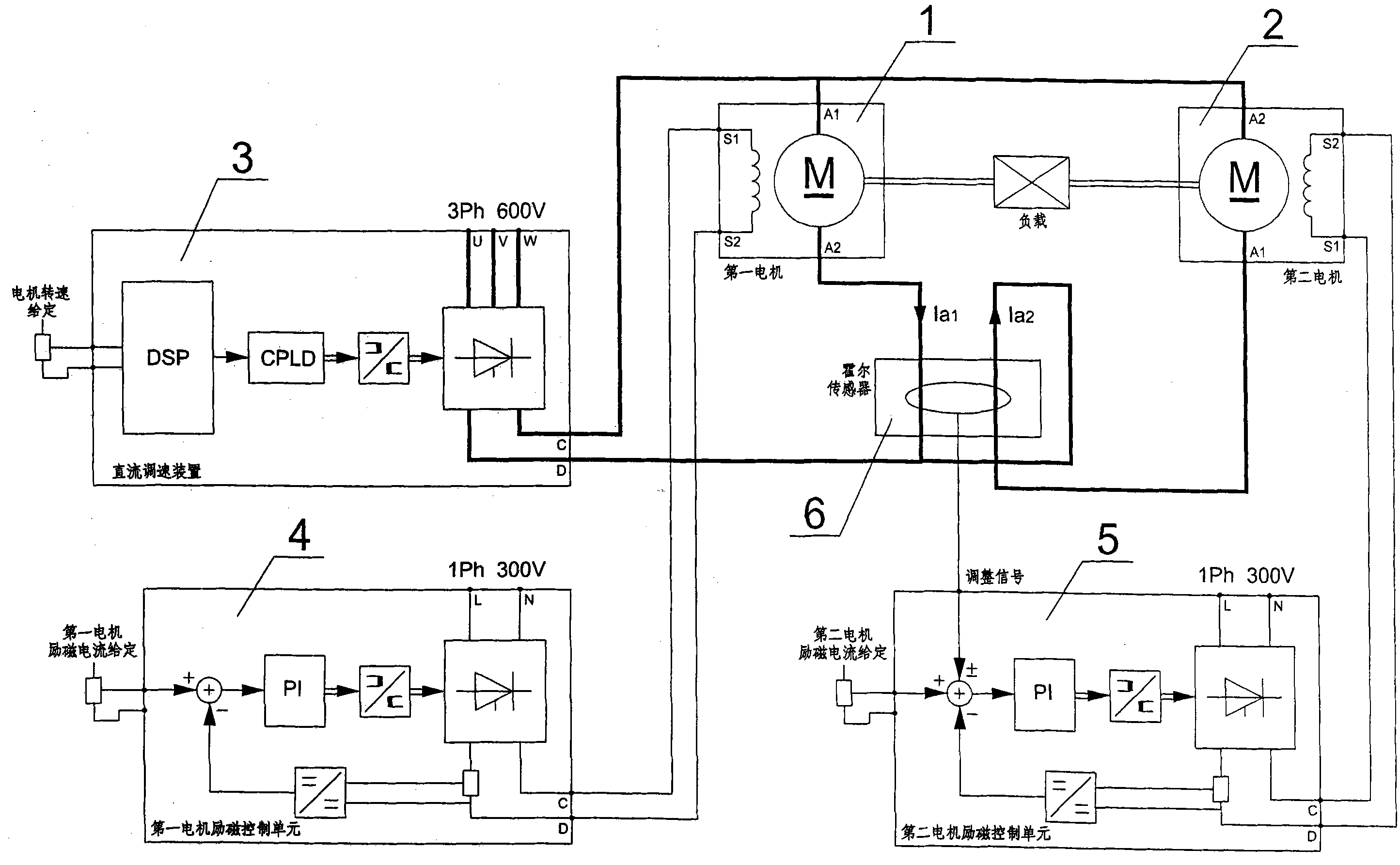

[0010] like figure 1 As shown in the figure, the load balancing control system with two DC separate excitation motors running coaxially has two DC separate excitation motors coaxially driving large-scale equipment, the armature windings of the two motors are connected in parallel, and a set of DC speed regulating device 3 is powered to realize Voltage regulation and speed regulation, in which the first motor 1 is equipped with a first excitation control unit 4, the second motor 2 is equipped with a second excitation control unit 5, and the Hall current sensor 6 detects the armature current difference between the two motors when the two machines are running value, and output an adjustment signal corresponding to the difference, the adjustment signal is superimposed on the given port of the excitation control unit 5 of the second motor 2, adjusts the excitation current value of the second motor 2, and automatically balances the output of the two motors.

[0011] The control meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com