Axial flux machine

A technology of axial magnetic flux and machines, applied in the field of generators or motors, new rotor design, can solve the problems of magnetic material deterioration, permanent magnet surface protection damage, complexity, etc., to reduce the risk of surface protection and simplify manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Overview:

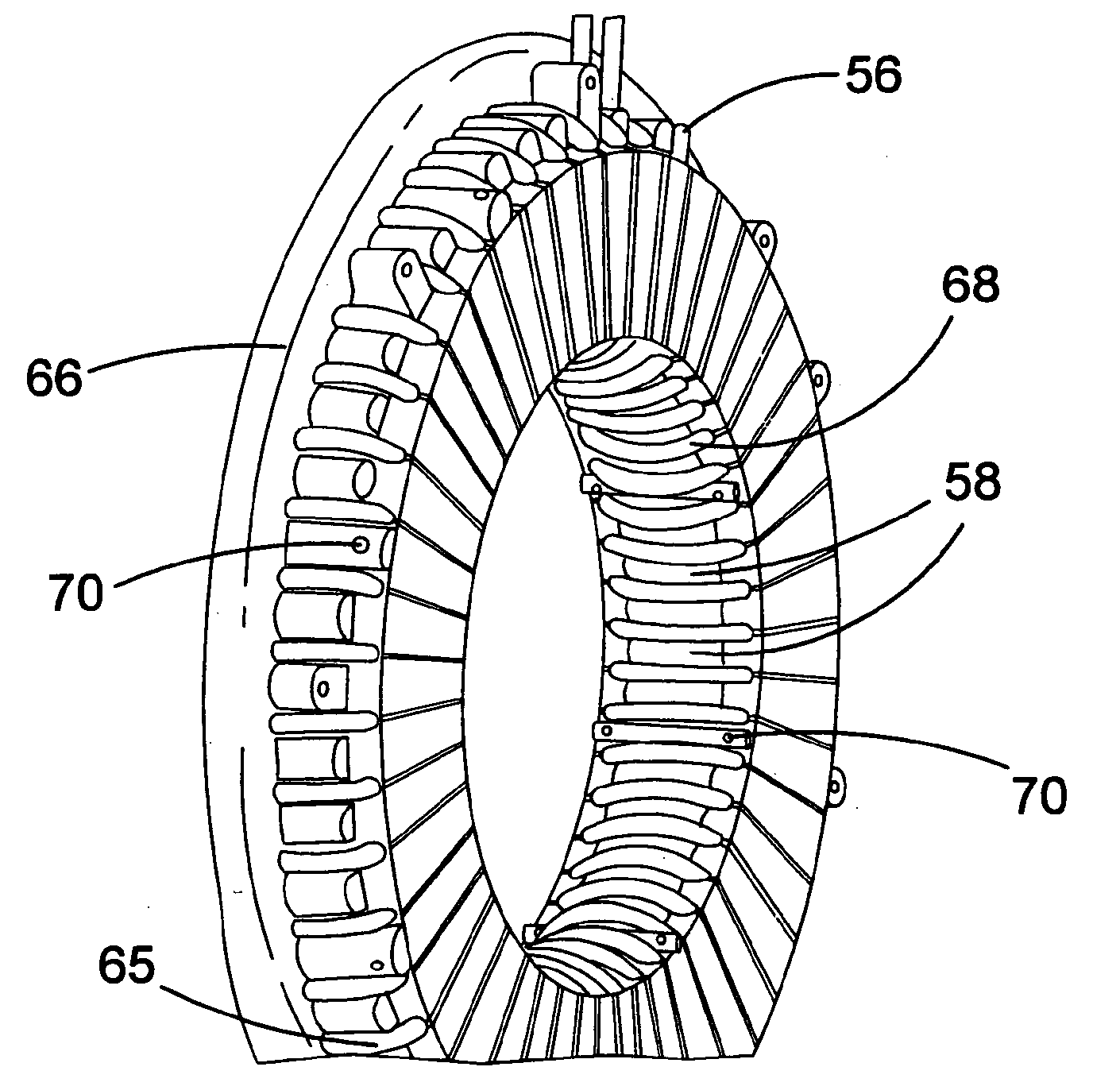

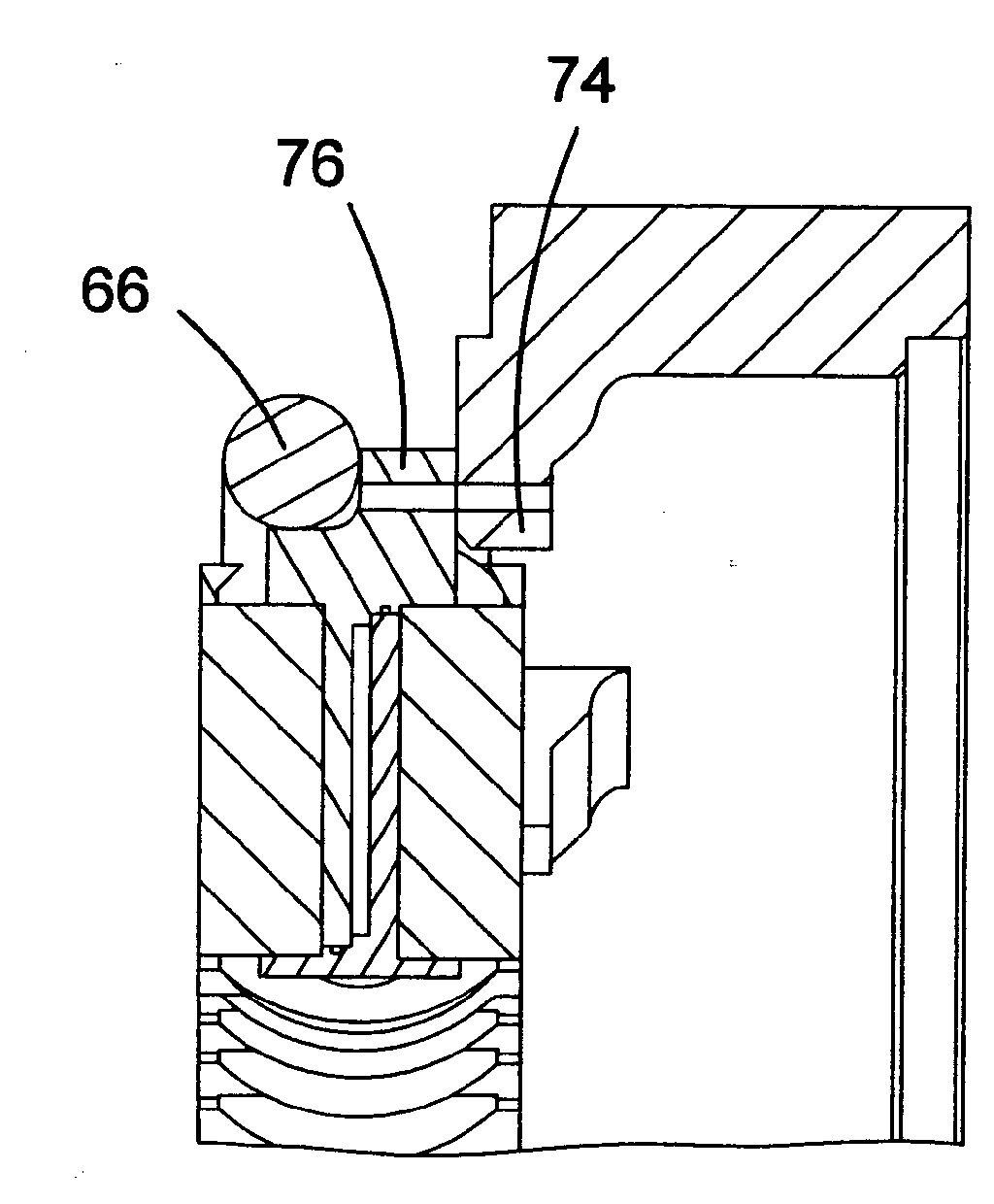

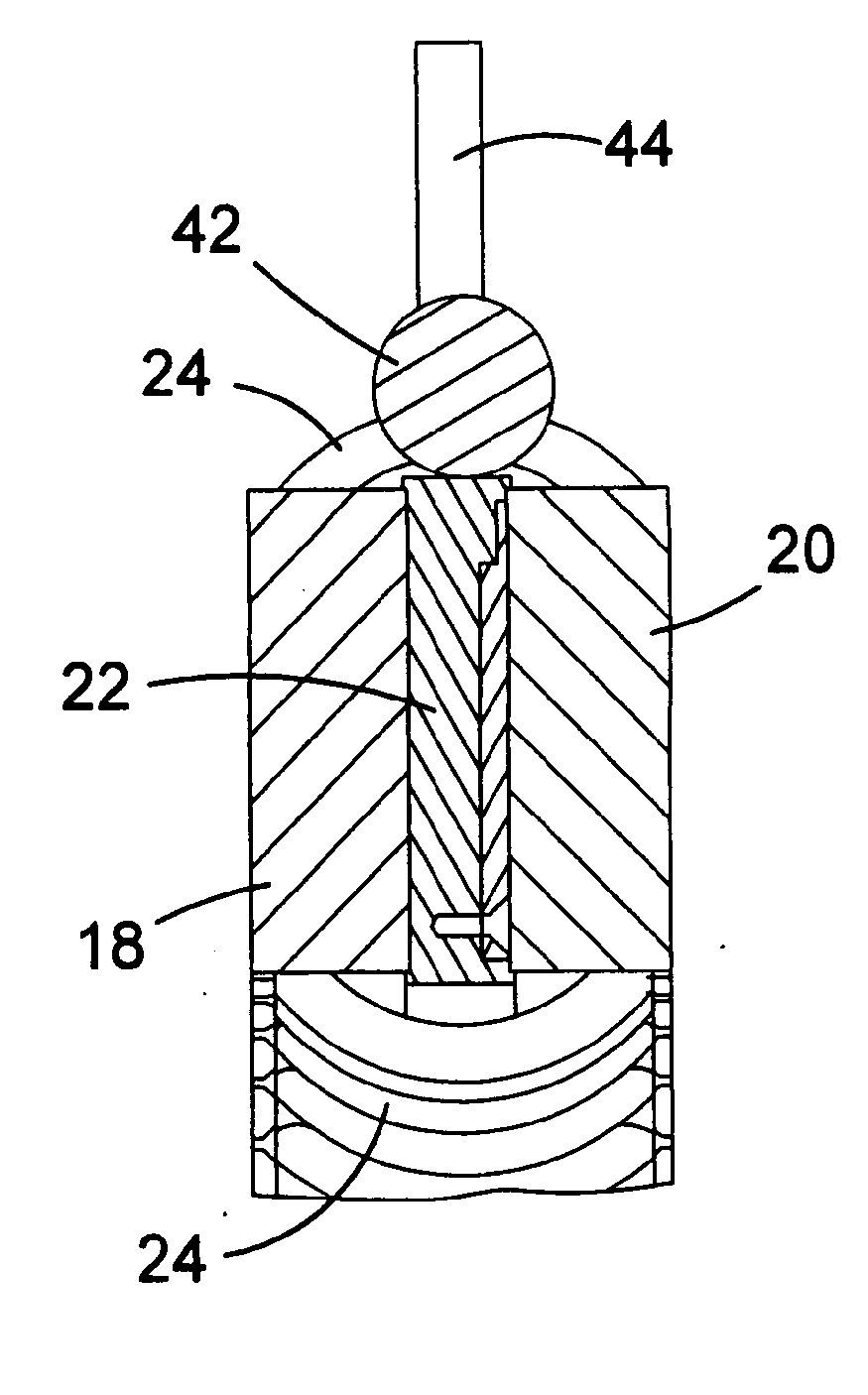

[0091] figure 1 Various components of an axial flux rotating electrical machine are shown. refer to figure 1 , the machine comprises a stator 10 sandwiched between two rotor disks 12 , 14 . The stator 10 includes two slotted laminated toroidal coils 18 , 20 and a cooling jacket 22 sandwiched between the two toroidal coils 18 , 20 . The two stator toroids 18, 20 can be manufactured by rolling a single strip of magnetic steel sheet. The seam 23 is formed on one side by an index punching machine as the rolling process takes place. Stator windings 24 are wound in slots in the finished stator.

[0092] The rotor disks 12, 14 are mounted on a common shaft and may be entirely ferromagnetic. Each disc carries a set of permanent magnets 16 with alternating south and north poles directed axially towards the stator. The rotor carries no alternating magnetic flux, and it can conveniently be constructed of cast iron. Preferably, the permanent magnets 16 are sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com