Rope saw

A wire saw and rope-shaped technology, applied in the field of new wire saws, to achieve the effects of large-scale promotion, less waste, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

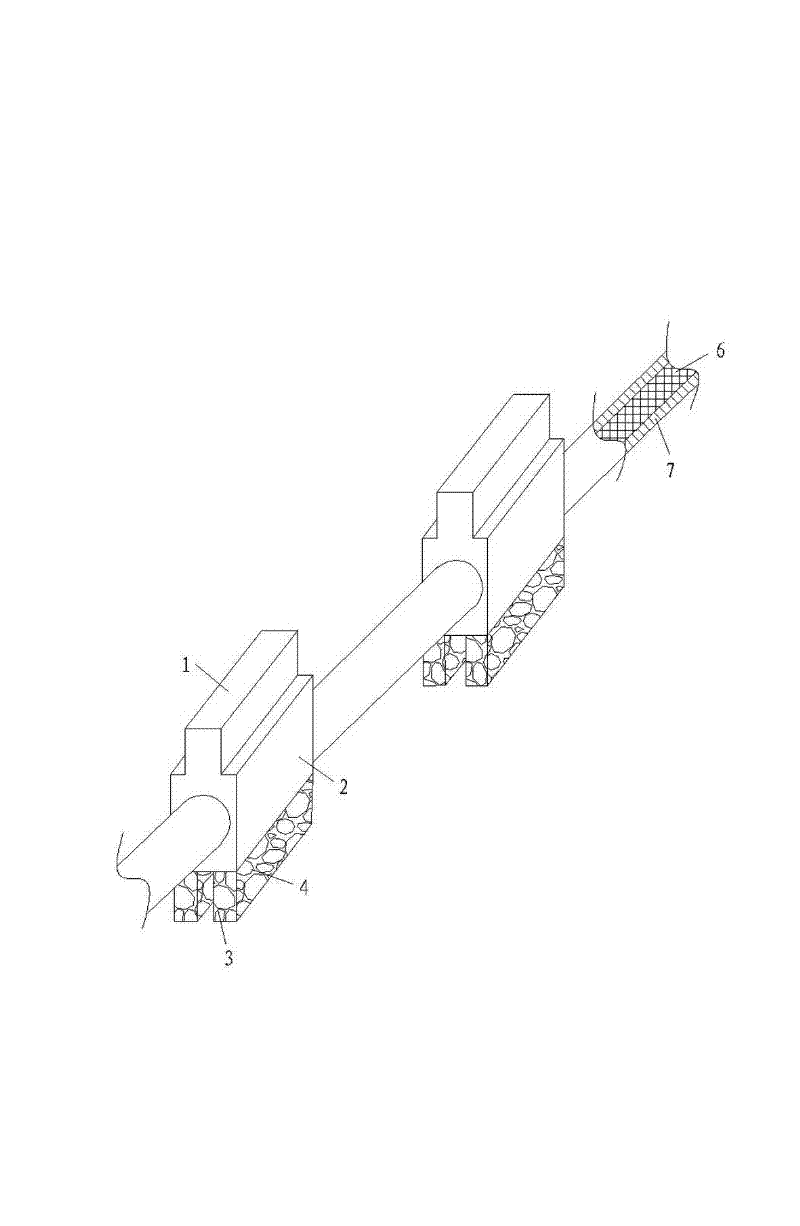

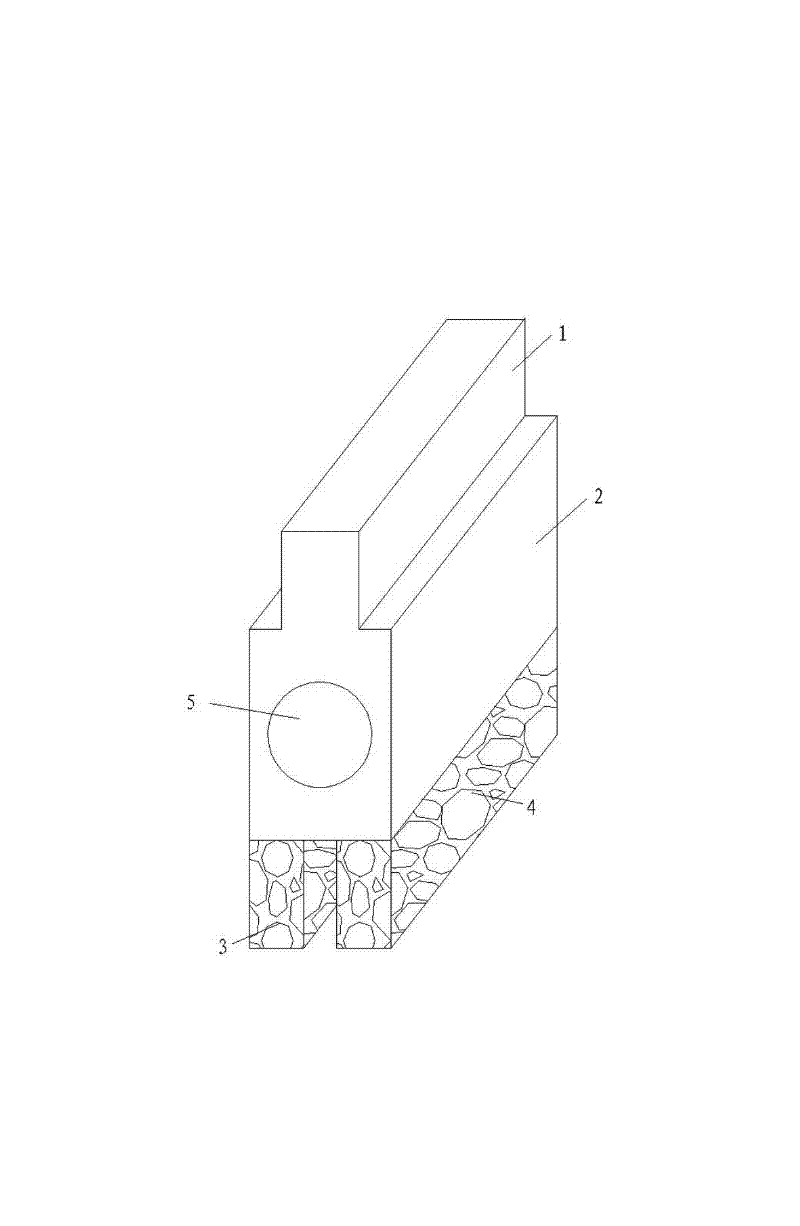

[0046] Such as figure 1 The manufacture method of the shown wire saw is as follows: use 45# steel to manufacture such as figure 2 The saw blade substrate shown has a side width of 2.4 mm, a height of 7.5 mm, and a length of 8 mm. Then, 50 mesh diamond particles 4 are deposited on the grinding and cutting part of the saw blade by chemical solution electrodeposition to form a saw blade. A spare piece. The prepared saw blade includes a pressure-receiving part 1 , a middle body 2 and a grinding and cutting part 3 , wherein the pressure-receiving part 1 is located above the middle body 2 , and the grinding and cutting part 3 is located below the middle body 2 . The pressure-receiving part 1 is set as a protrusion, so as to be compatible with Figure 5 The grooves of the pressure guide plate shown in the figure fit, there is a through hole 5 in the middle body, and the grinding and cutting part 3 is composed of two parallel square bars.

[0047] Clean the surface of the steel wi...

Embodiment 2

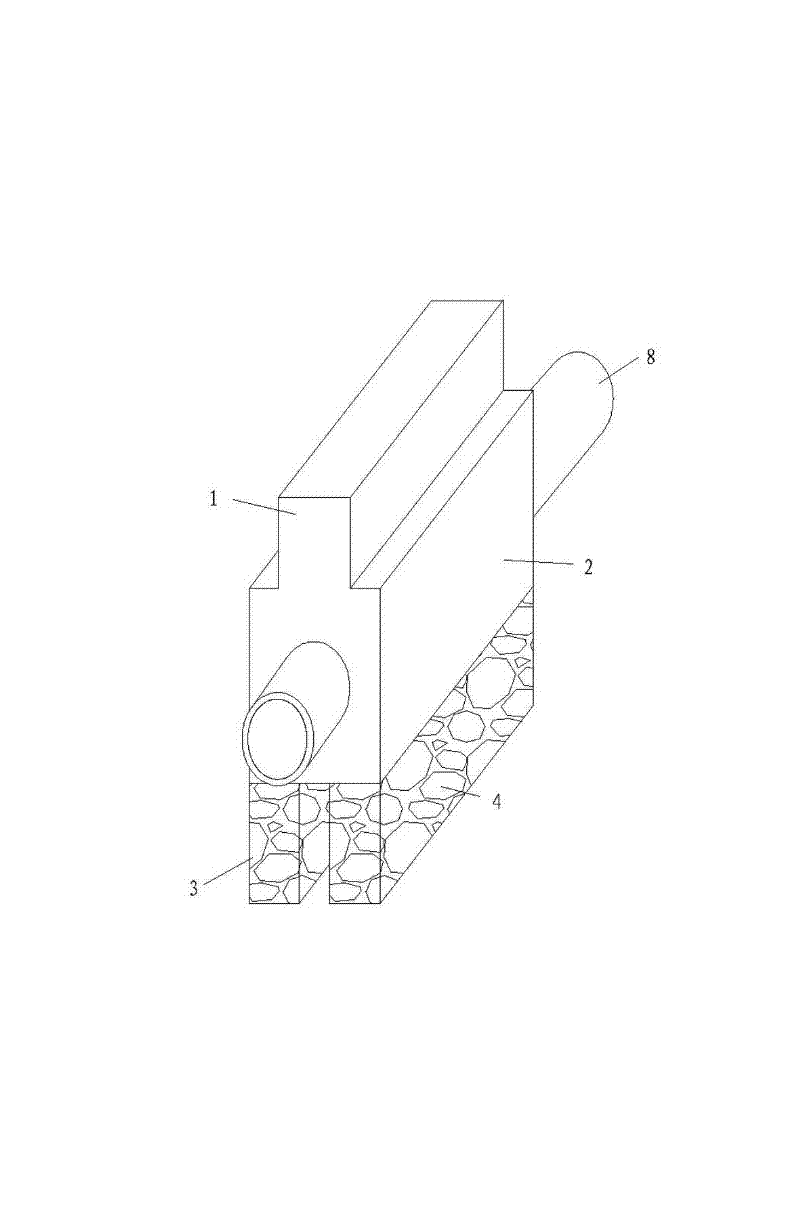

[0050] Made of 45# steel such as image 3 The saw blade base shown has a side width of 2.4 mm, a height of 9 mm, and a length of 10 mm, with 4 mm long fixing sleeves on both sides of the base. Then apply brazing material and diamond particles 4 on the grinding and cutting part 3 of each saw blade substrate, then place it in a vacuum furnace and slowly raise the temperature to 860°C for brazing, and then make a brazed diamond saw blade after cooling. .

[0051] After the steel wire rope 6 with a diameter of 1.5 mm is cleaned with a solvent, the brazed diamond saw blade prepared above is inserted into the steel wire rope 6, and the distance between the saw blades is adjusted to be 25 mm and the direction of each saw blade so that They keep the same direction, and then the fixed ends on both sides of the saw blade are compressed and fixed on the wire rope by hydraulic pliers. After this process is completed, polyurethane is applied to the space between the saw blades for reinfo...

Embodiment 3

[0054] In this embodiment, the saw blade structure is as Figure 4 As shown, there are two through-holes 5 parallel to each other and arranged on the same vertical plane on the middle body 2 of the saw blade. Refer to Embodiment 1 for other situations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com