Method and device for precisely processing nuclear power station condensation water

A technology for condensate polishing and nuclear power plants, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of simplifying pipelines and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

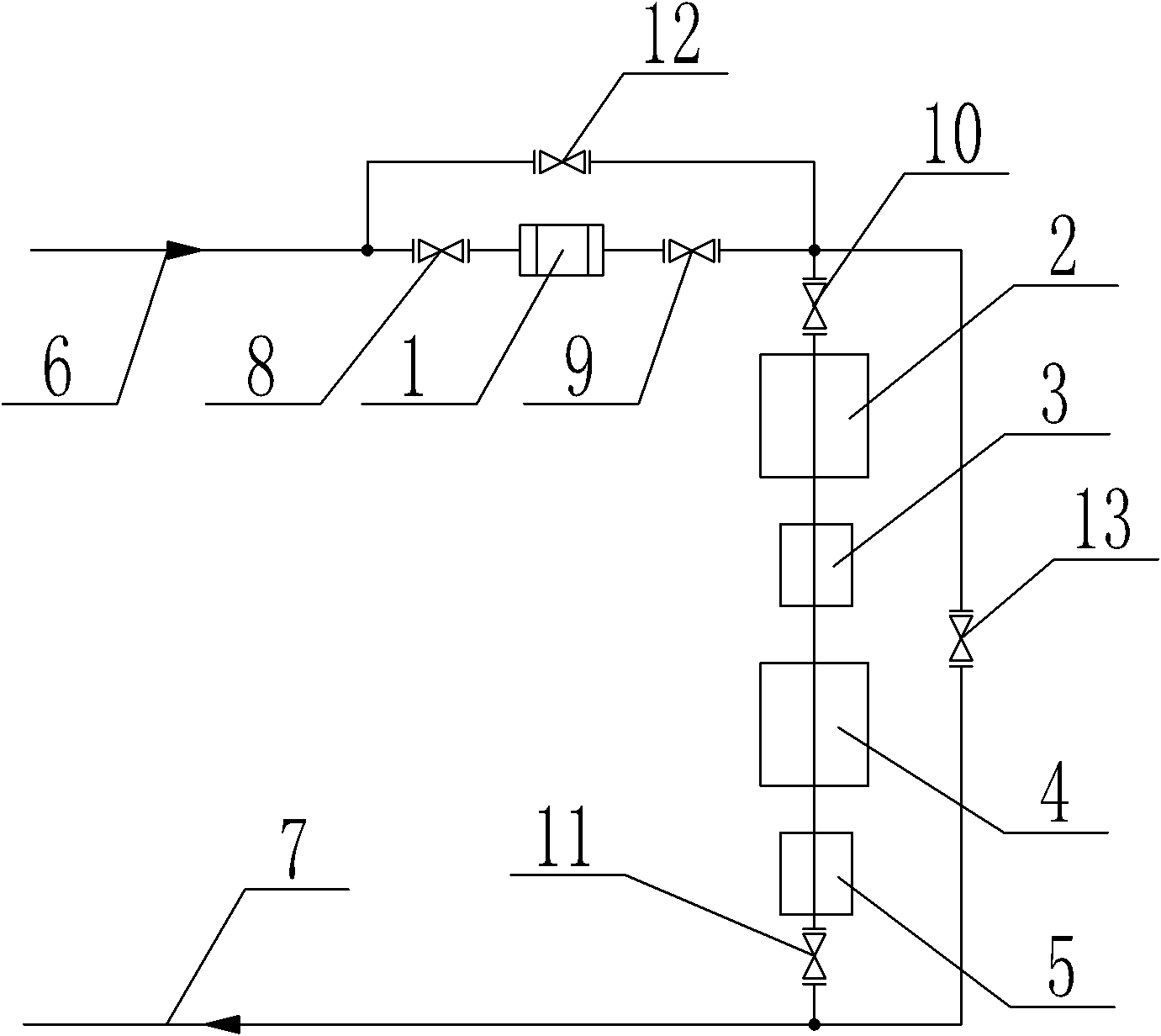

[0033] Embodiment 1 of the present invention: a method for polishing condensate in a nuclear power plant, by controlling the open and closed state of the valve in the pipeline to adjust the condensate to be treated to flow through the pre-filter, cation exchanger, and resin trap A , anion-cation exchanger and resin trap B in order to meet the advanced treatment requirements for condensed water under different operating conditions. In addition to ionic impurities, the condensed water to be advanced treatment also contains metal corrosion products and suspended impurities, and the metal corrosion products are mainly iron oxides. When the iron content of metal corrosion products in the condensed water to be advanced treatment is greater than 1000μg / When L, the purification of condensed water includes the following steps:

[0034] Step a: Open valve 1 8, valve 2 9 and valve 6 13, close valve 5 12, valve 3 10 and valve 4 11, the condensed water to be processed enters the pipeline ...

Embodiment 2

[0039] Embodiment 2 of the present invention: a method for polishing condensate in a nuclear power plant, by controlling the open and closed state of the valve in the pipeline to adjust the condensate to be treated to flow through the pre-filter, cation exchanger, and resin trap A , anion-cation exchanger and resin trap B in order to meet the advanced treatment requirements for condensed water under different operating conditions. In addition to ionic impurities, the condensed water to be advanced treatment also contains metal corrosion products and suspended impurities, and the metal corrosion products are mainly iron oxides. When the iron content of metal corrosion products in the condensed water to be advanced treatment is greater than 1000μg / When L, the purification of condensed water includes the following steps:

[0040] Step a: Open valve 1 8, valve 2 9 and valve 6 13, close valve 5 12, valve 3 10 and valve 4 11, the condensed water to be processed enters the pipeline ...

Embodiment 3

[0045] Embodiment 3 of the present invention: a method for fine treatment of condensate in a nuclear power plant, by controlling the opening and closing of the valve in the pipeline to adjust the condensate to be treated to flow through the pre-filter, cation exchanger, and resin trap A , anion-cation exchanger and resin trap B in order to meet the advanced treatment requirements for condensed water under different operating conditions. The condensed water to be advanced treatment contains not only ionic impurities, but also metal corrosion products and suspended impurities. Among them, the metal corrosion products are mainly iron oxides. When the iron content of metal corrosion products in the condensed water to be advanced treatment is greater than 1000 μg / When L, the purification of condensed water includes the following steps:

[0046]Step a: Open valve 1 8, valve 2 9 and valve 6 13, close valve 5 12, valve 3 10 and valve 4 11, the condensed water to be processed enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com