Adjustable vacuum sucker device for assembling and adjusting lens of photoetching machine

A vacuum suction cup and adjustable technology, which is applied in the field of deep ultraviolet lithography machine projection objective lens manufacturing and assembly, can solve problems such as component damage, and achieve the effect of simple structure and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

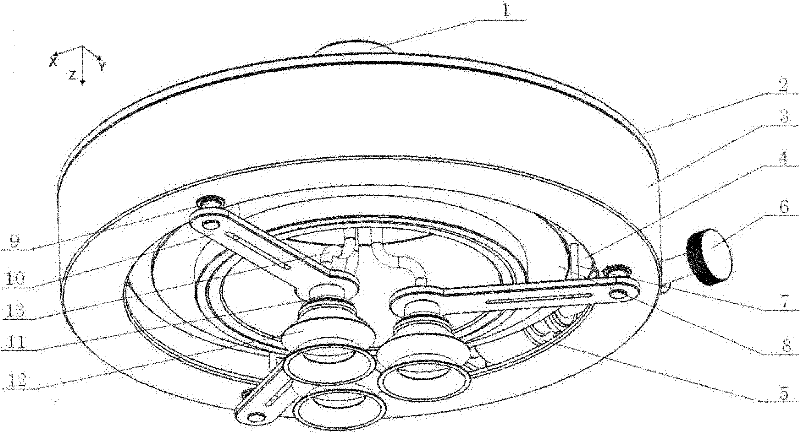

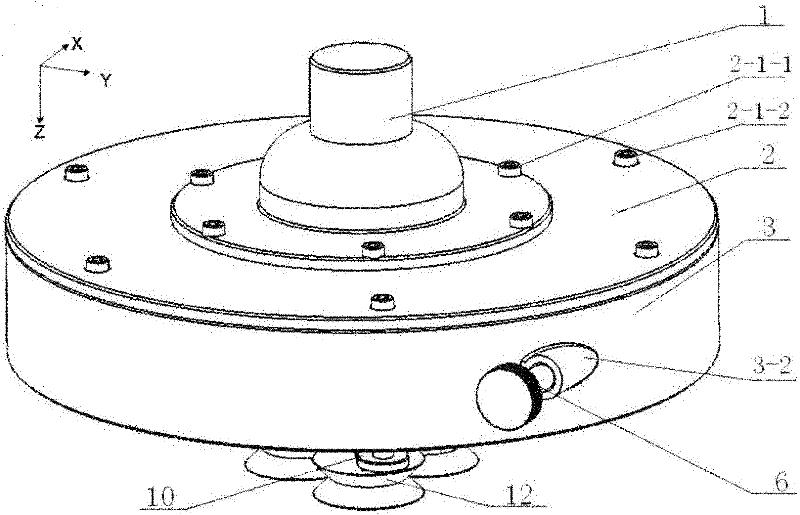

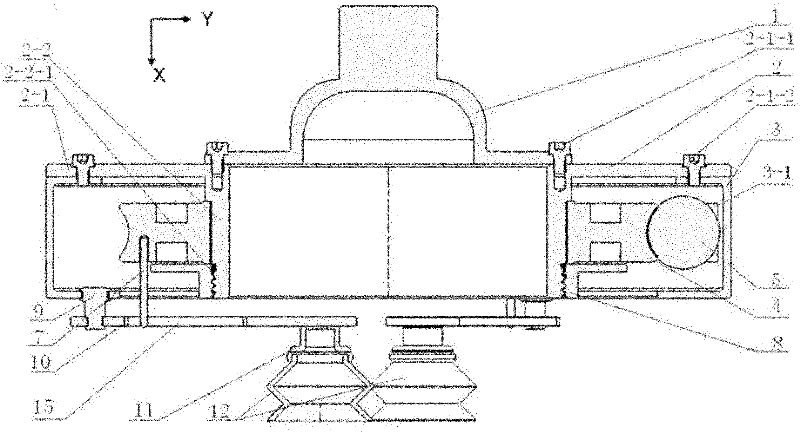

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment, an adjustable vacuum chuck used in the manufacture and adjustment of lithography machine lenses, the device includes an adapter 1, an upper cover 2, a housing 3, a worm wheel 4, a worm 5, an adjustment handle 6, and a dial pin 7 , positioning ring 8, pin shaft 9, connecting rod 10, suction nozzle joint 11, rubber suction nozzle 12 and vacuum suction pipe 13, the adapter 1 is tightly connected with the upper cover 2, and the outer shell 3 is fixed on the upper cover 2; The bottom of the upper cover 2 is a hollow shaft 2-2 with an external thread 2-2-1; the internal thread of the positioning ring 8 cooperates with the external thread of the hollow shaft 2-2; the positioning ring 8 connects the worm wheel 4 Axially positioned on the hollow shaft 2-2, the housing 3 is provided with a positioning mechanism supporting the worm 5 and the adjustment handle 6, the worm 5 is fixed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com