Linear interconnection method and device for optical fiber composite power cable

A power cable and optical fiber composite technology, which is applied in the direction of cable joints, optical waveguide coupling, etc., can solve the problems of wasting capital expenses and labor, design, infrastructure construction and manufacturing difficulties, and the number of tension towers is small, so as to save costs, The effect of simple structure and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

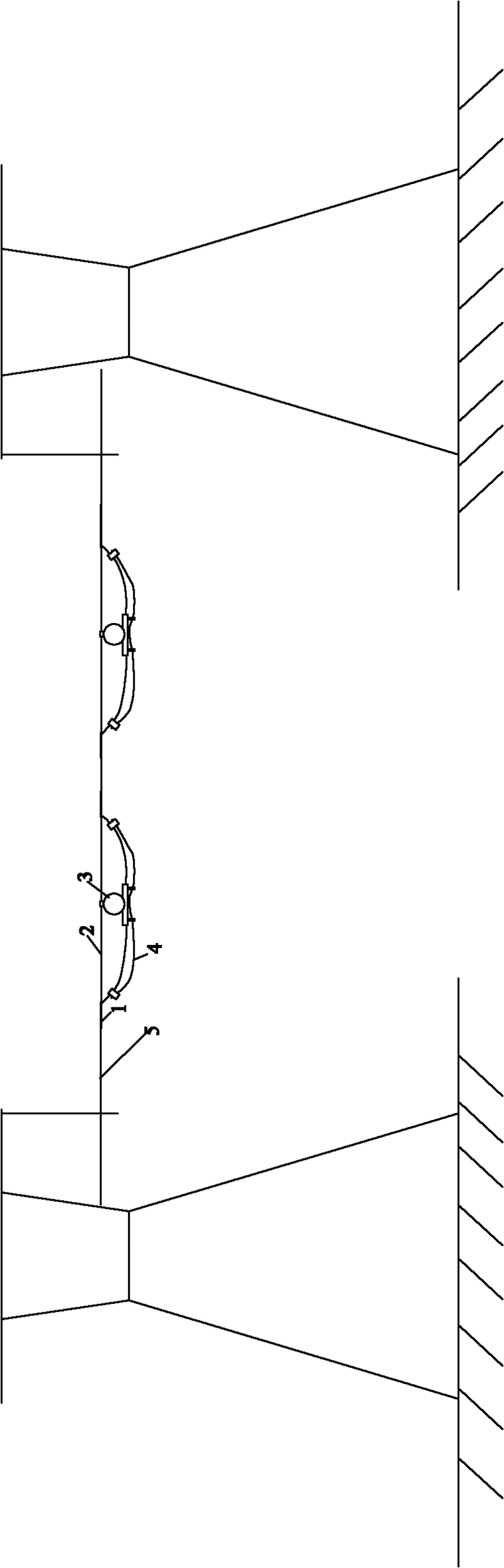

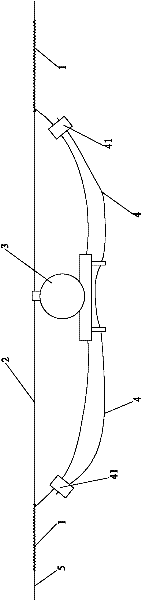

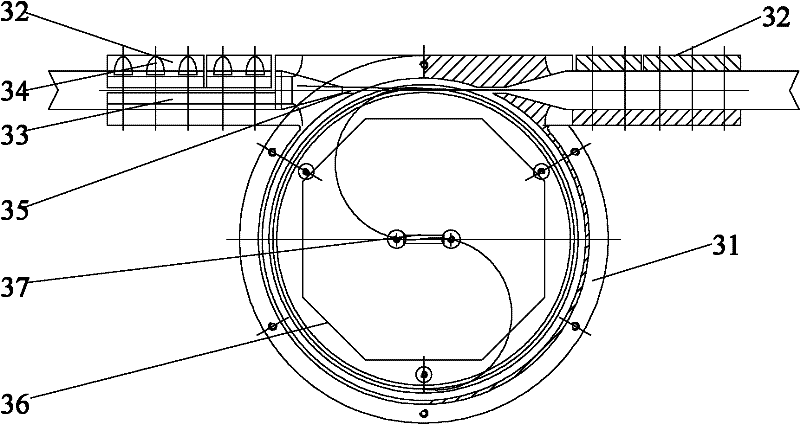

[0020] Such as figure 1 with figure 2 As shown, the optical fiber composite power cable linear splicing device according to the present invention includes tension-resistant pre-twisted wire fittings 1, which are respectively arranged at the two ends of the optical fiber composite power cable 5 to be connected, and the tension members 2 are respectively connected to two The tension-resistant pre-twisted fitting 1 at the opposite end is used to tighten and fix the optical fiber composite power cable 5; the intermediate splice box 3 is provided with two wire inlets, respectively introducing the optical fiber conductors of the optical fiber composite power cable 5 to be connected. When connecting two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com