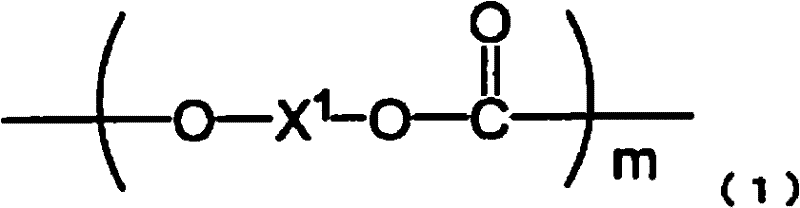

Polycarbonate resin composition and molded article

A technology of polycarbonate resin and composition, which is applied in the field of polycarbonate resin composition, can solve the problems of reduced impact resistance, insufficient flame retardancy, difficulty in expressing the impact resistance of shell materials, etc., and achieve improved flame retardancy performance and impact resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

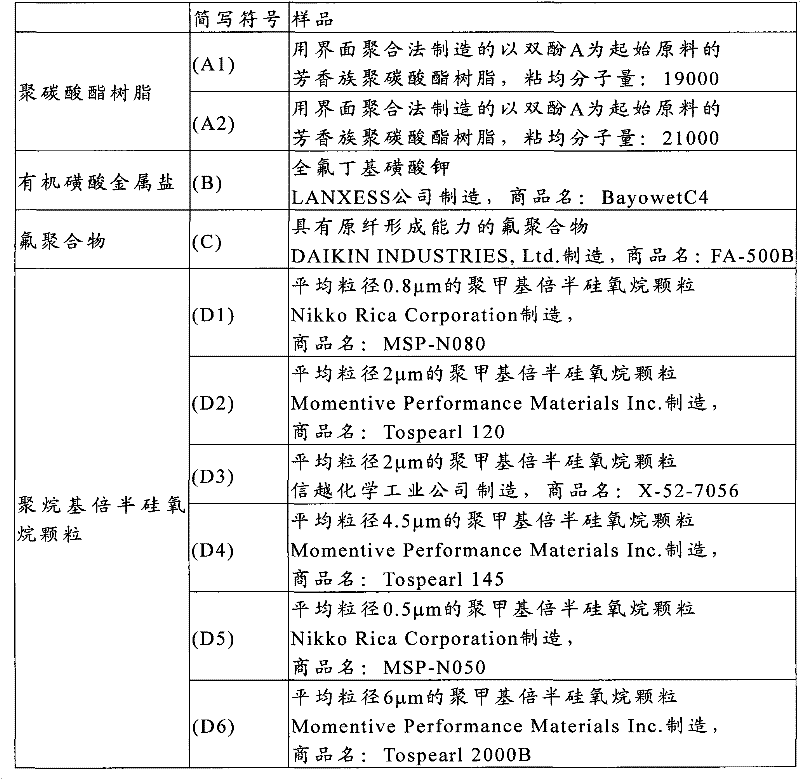

Embodiment 1~15、 comparative example 1~12

[0283] [Preparation of test piece]

[0284] The pellets obtained by the above-mentioned production method were dried at 120°C for 5 hours, and then injection-molded using a J50-EP injection molding machine manufactured by Nippon Steel Works at a cylinder temperature of 290°C and a mold temperature of 80°C. Formed into a UL test specimen with a length of 125 mm, a width of 13 mm, and a thickness of 0.8 mm, a flat test specimen (90 mm x 50 mm x 1-3 mm thick in two stages), and an ASTM tensile impact test specimen according to ASTM D1822 TypeS ( Thickness 3.2mm).

[0285] The pellets obtained by the above-mentioned production method were dried at 120°C for 5 hours, and then the cylinder temperature was 290°C and the mold temperature was 80°C using SYCAP M-2 manufactured by Sumitomo Heavy Industries, Ltd., with a mold clamping force of 75T. Injection molding was performed to form an ISO multi-functional test piece (3mm).

[0286] In addition, the pellets obtained by the above-me...

Embodiment 16~19、 comparative example 13

[0313] [Evaluation of Flame Retardancy]

[0314] The pellets obtained by the above-mentioned production method were dried at 120°C for 5 hours, and then injection-molded using an SE100DU injection molding machine manufactured by Sumitomo Heavy Industries Co., Ltd. at a cylinder temperature of 290°C and a mold temperature of 80°C. It was molded into a test piece for a UL test having a length of 125 mm, a width of 13 mm, and a thickness of 0.75 mm.

[0315] The obtained 0.75 mm test piece for UL test was subjected to humidity adjustment for 48 hours in a thermostatic chamber at a temperature of 23° C. and a humidity of 50%, and carried out in accordance with the UL94 test (combustion test of plastic materials for machine parts) in the same manner as above.

[0316] In addition, in Table 8, the result of the UL94 test is shown as "flame retardancy (0.75 mm)", and the total afterflame time (total burning time) of the five samples is shown as "Σt".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com