Injector for injecting high-pressure fuel into the combustion chamber of an internal combustion engine

A technology of injectors and internal combustion engines, applied in fuel injection devices, special fuel injection devices, machines/engines, etc., can solve problems such as injector function failure, erosion, wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

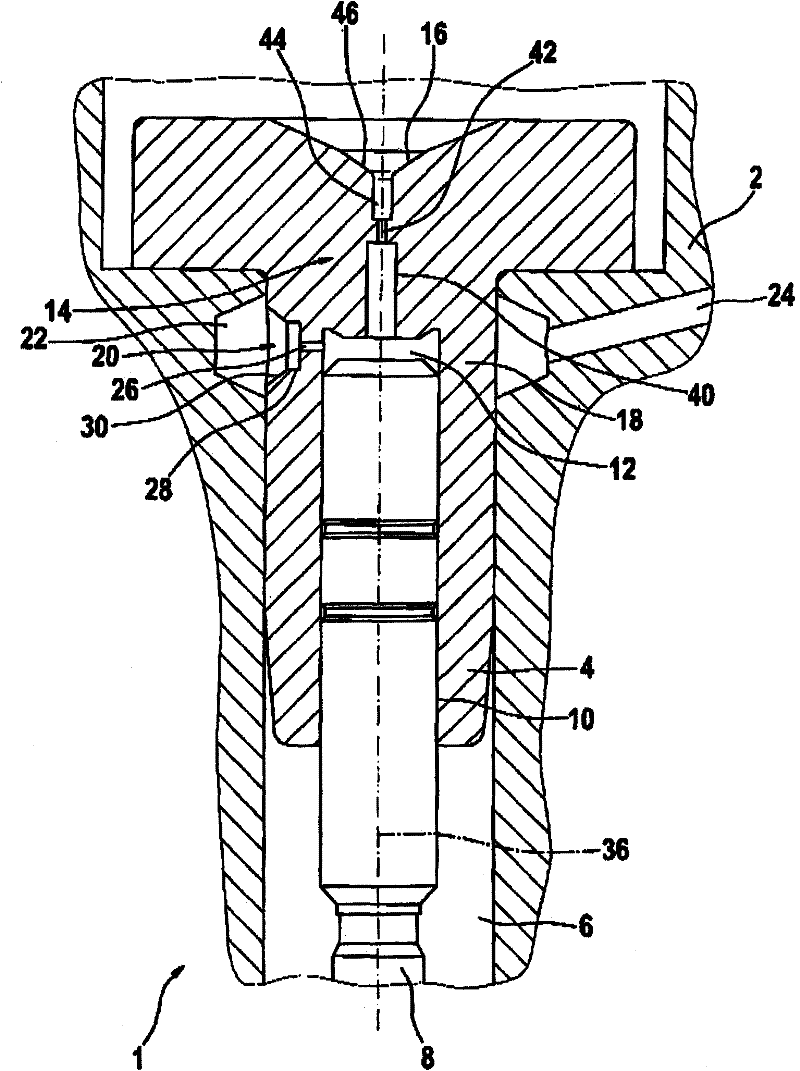

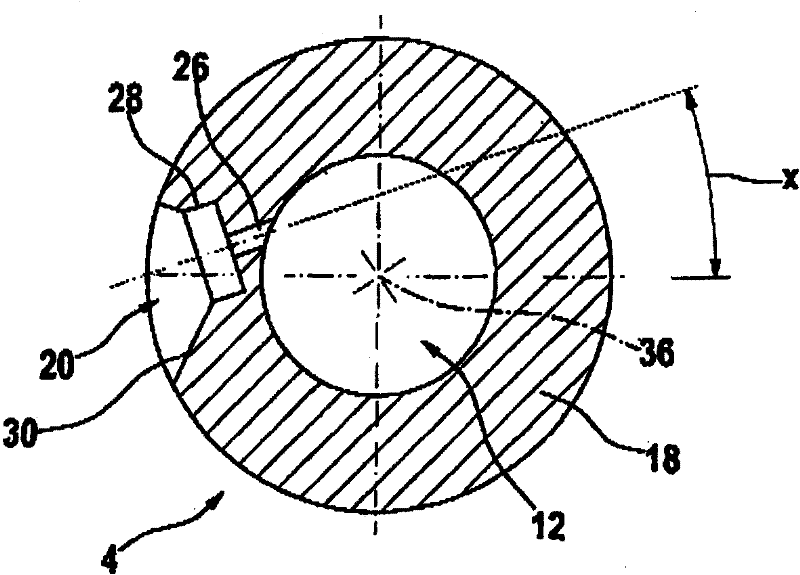

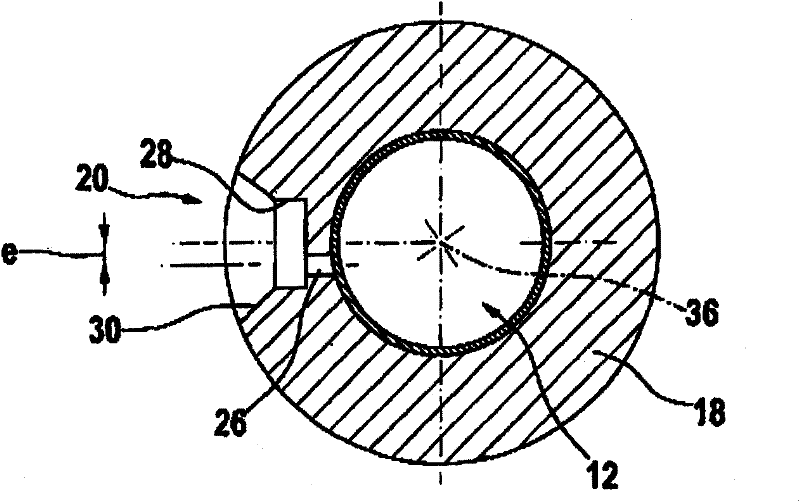

[0025] figure 1 A partial view of an axial section of an injector 1 with a valve section 4 inserted into a housing 2 of the injector 1 is shown. The valve section 4 is arranged here in a multi-staged axial recess 6 of the housing 2 , in which the valve control piston 8 is also received centrally and movable axially and rotationally. exist figure 1 The lower end of the injector housing 2 shown in figure 1 Nozzle body, not shown, in which is arranged a nozzle needle arranged coaxially with respect to the valve control piston 8, which nozzle needle opens the injection nozzles in stages for injecting high-pressure fuel into the internal combustion engine in the combustion chamber.

[0026] An axial bore 10 is provided in the valve section 4 arranged in the injector housing 2 , which extends through the valve section 4 in the axial direction of the valve section and is divided here into zones of different inner diameters. part. In this case, the valve control piston 8 is recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com