Tin-zinc base composite soldering flux

A technology of composite welding and zinc solder, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of wettability and oxidation resistance not fundamentally solved, and the difficulty of popularization and application of solder, so as to achieve a combination of Tight, uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: In the tin-zinc based composite solder of the present invention, the weight percentages of the components are: 99% tin-zinc solder matrix, 1% Fe magnetic particles, and the average particle size of the Fe magnetic particles is 10 μm. The content of Zn in the tin-zinc solder base is 2% by weight of the tin-zinc base solder base, and the balance is Sn.

Embodiment 2

[0028] Example 2: In the tin-zinc based composite solder of the present invention, the percentage by weight of each component is: tin-zinc solder matrix 85%, Co magnetic particles 15%, and the average particle diameter of Co magnetic particles is 50 μm. The content of Zn in the tin-zinc solder base is 6% by weight of the tin-zinc base solder base, and the balance is Sn.

Embodiment 3

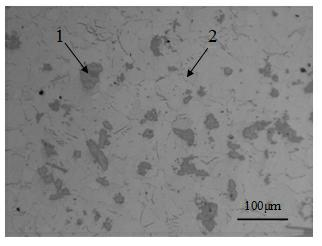

[0029] Example 3: In the tin-zinc based composite solder of the present invention, the weight percent of each component is: 98% of tin-zinc solder matrix, 2% of Ni magnetic particles, and the average particle size of Ni magnetic particles is 30 μm. The content of Zn in the tin-zinc solder base is 9% by weight of the tin-zinc base solder base, and the balance is Sn. figure 1 Its metallographic microstructure photo.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap