Halogen-free soldering flux

A flux and halogen technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as non-compliance, halogen residues, environmental hazards, etc., and achieve low post-weld corrosion, high safety performance, The effect of saving extra expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

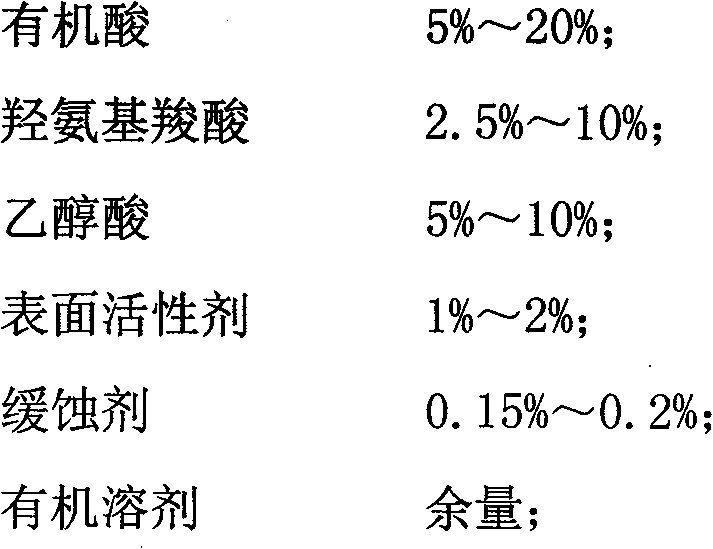

[0016] This embodiment is a halogen-free flux, including the following components:

[0017]

[0018]

[0019] Above-mentioned percentage is mass percentage;

[0020] The organic acid is succinic acid; the hydroxyaminocarboxylic acid is β-amino-α-hydroxycarboxylic acid; the surfactant is butylphenol polyoxyethylene ether; the corrosion inhibitor is benzotriazepam Azole; Described organic solvent is dehydrated alcohol.

[0021] The relevant materials and parameters of this embodiment are shown in Table 1.

Embodiment 2 to Embodiment 6

[0023] Embodiment 2 to Embodiment 6 are basically the same as Embodiment 1, except that the proportion of the components is different from that of Embodiment 1, and the relevant materials and parameters of Embodiment 2 to Embodiment 6 are shown in Table 1.

[0024] Table 1

[0025]

Embodiment 7

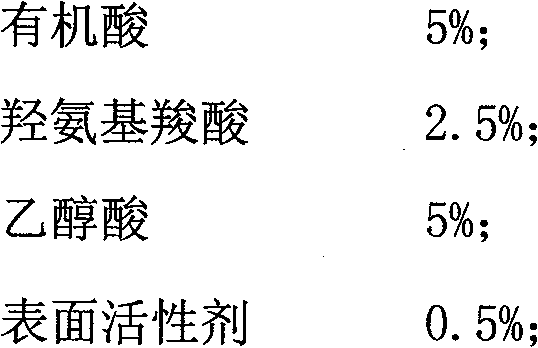

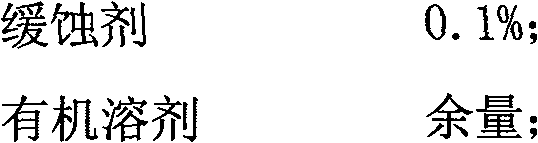

[0027] This embodiment is a halogen-free flux, including the following components:

[0028]

[0029]

[0030] Above-mentioned percentage is mass percentage;

[0031] The organic acid is adipic acid; the hydroxyaminocarboxylic acid is α-hydroxycarboxylic acid amide; the surfactant is octylphenol polyoxyethyl ether; the corrosion inhibitor is α-mercaptobenzothiazole; Described organic solvent is ethylene glycol benzoxazole.

[0032] The relevant materials and parameters of this embodiment are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com