Uncapping device and vacuum test tube uncapping machine with uncapping device

A test tube cap remover and cap removal technology, which is applied in the direction of stopper removal, etc., can solve problems such as inability to open, and achieve the effects of simple structure, free from aerosol pollution, and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

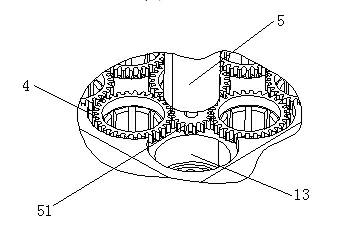

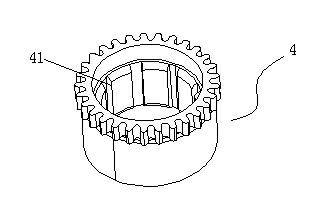

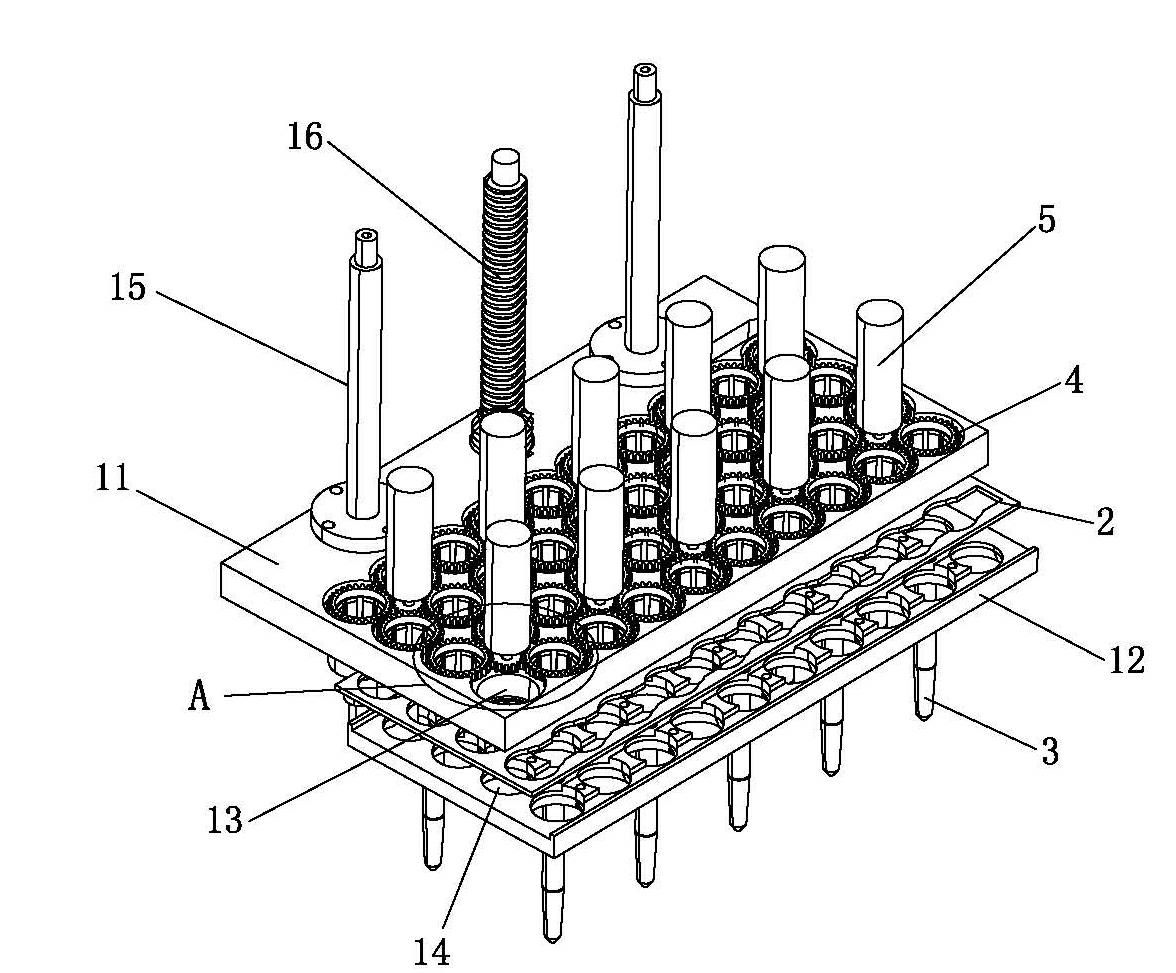

[0020] Such as Figure 1-3 As shown, a capping device of a vacuum test tube capping machine includes a capping rack, an elevating drive device for the capping rack, a capping plate 2, a capping plate driving device, and a top rod 3. The capping rack includes an upper capping rack 11 and a lower capping rack 12. The capping plate 2 is provided between the upper capping rack 11 and the lower capping rack 12, and at least one test tube is provided on the upper capping rack 11 and the lower capping rack 12 respectively. The through holes 13 and 14 pass through; the through hole 13 on the upper detachment frame 11 is cylindrical, and the through hole 14 on the lower detachment frame 12 is in the shape of a truncated cone. The number of through holes on the upper detachment frame and the lower detachment frame is sum The positions correspond to each other. There are decapping driving gears 51 distributed on the upper capping rack. At least one capping gear 4 is engaged with each capp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com