Axial-flow compressor stator blade

A technology of stator blades and compressors, applied in mechanical equipment, non-variable pumps, machines/engines, etc., can solve problems such as compressor efficiency reduction, hub-corner stall, surge, etc., to reduce airflow loss, Improve the flow field and reduce the loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, structural representation of the present invention is shown.

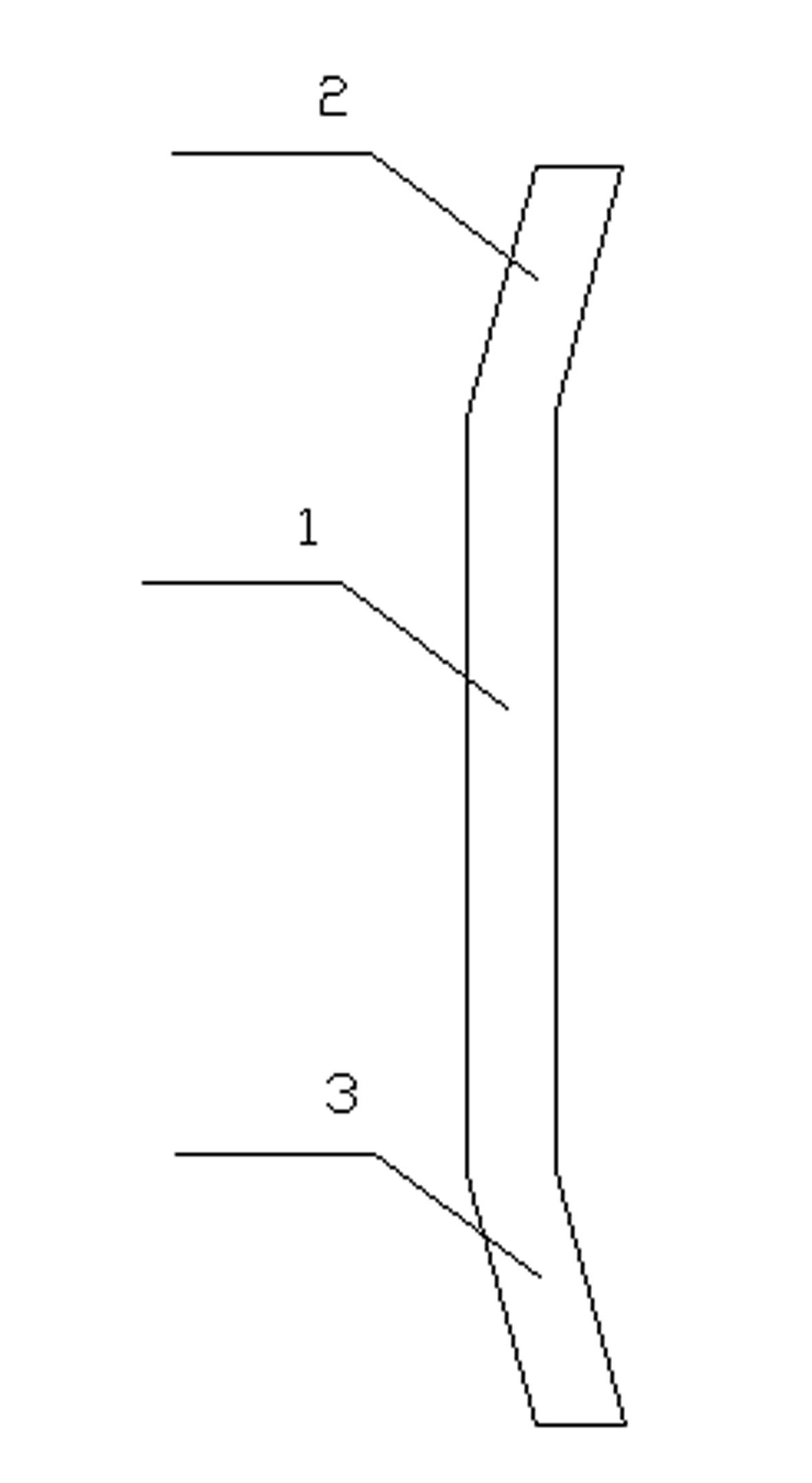

[0018] figure 1 As shown, a stator blade of an axial flow compressor, the stator blade 4 includes a blade root part 3, a blade middle part 1 and a blade tip part 2, the blade tip part 2 is tangentially curved 15°-25°, and the blade root part 3 The tangential positive bending is 15°-25°, and the stacking line of the middle part of the leaf is a straight line; the two ends of the middle part of the leaf are smoothly transitioned to the root part and the tip part of the blade respectively; 20% of the blade length.

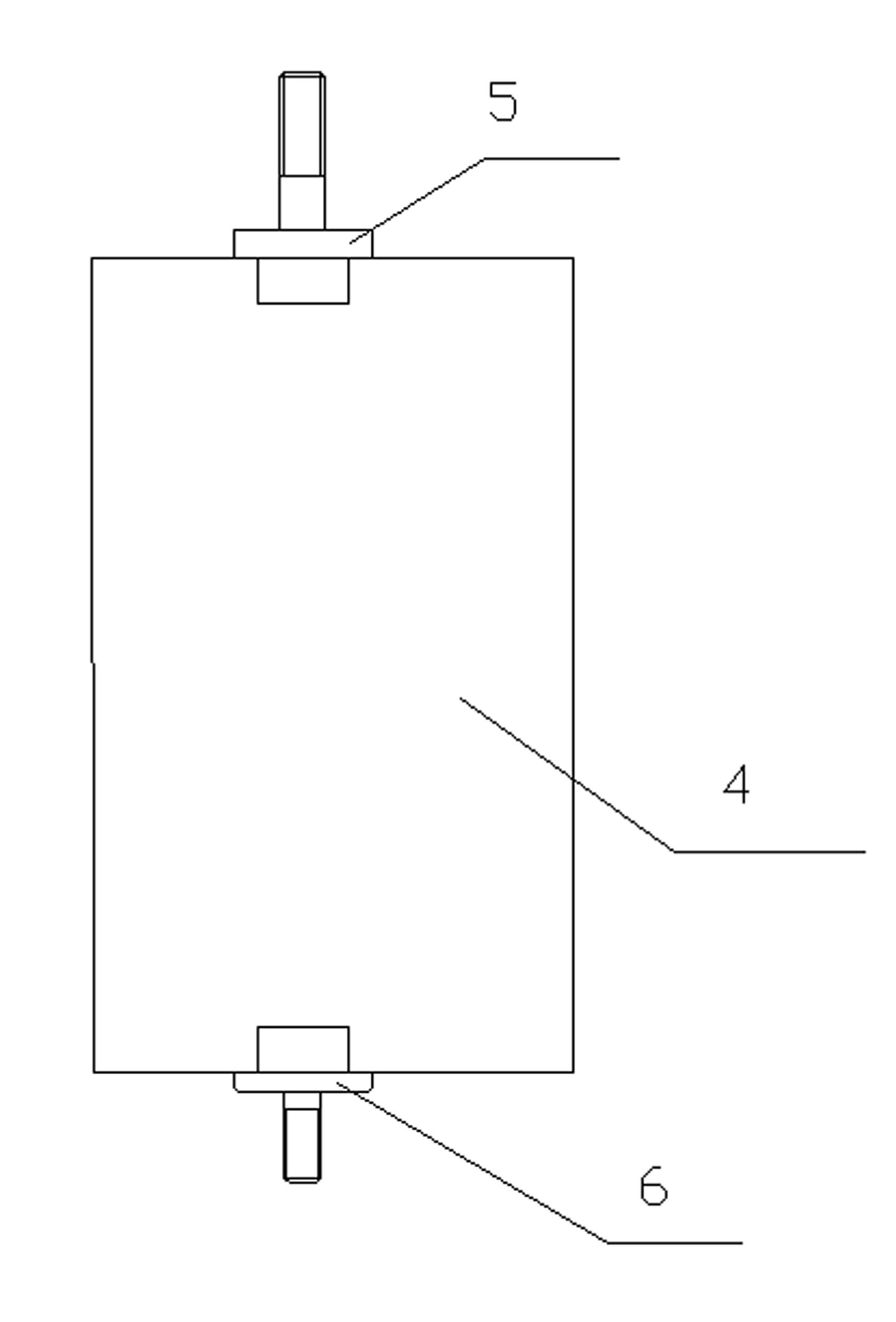

[0019] figure 2 As shown, when the stator blade 4 is installed and used, the blade root 3 and the inner mounting handle 6 are fixed and connected to one end of the compressor hub, and the blade tip part 2 and the outer mounting handle 5 are fixed and then connected to one end of the compressor casing.

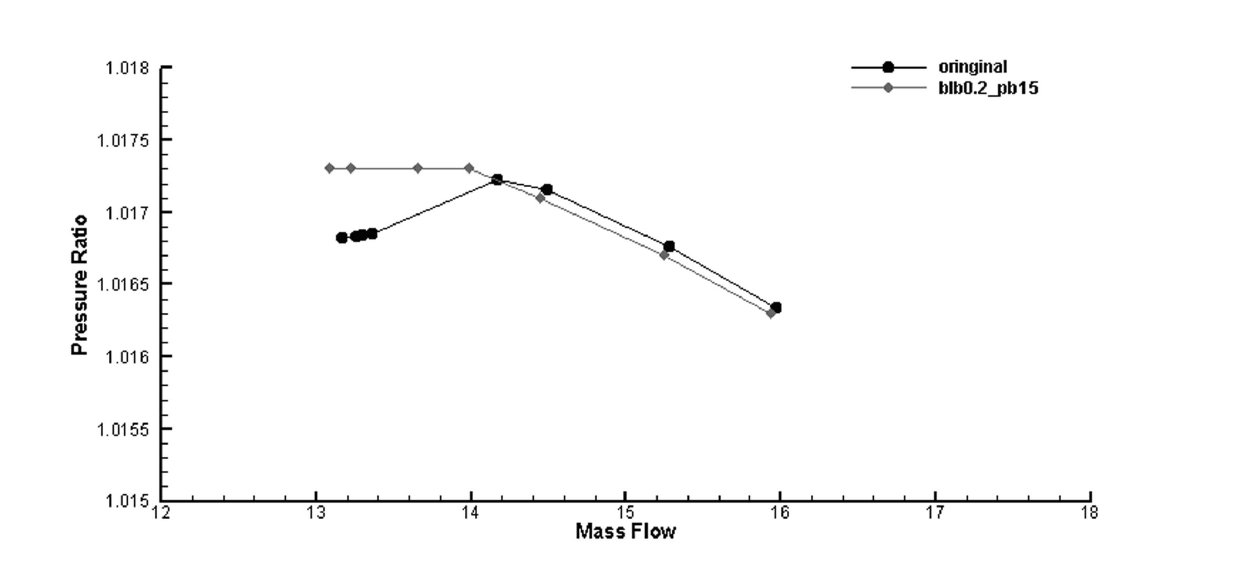

[0020] Figure 3-5 As shown, the pressure ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com