Full-automatic hydraulic press

A press and fully automatic technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of small demand for special-shaped bricks, unable to meet the firing output of tunnel kilns, etc., to reduce labor intensity of workers, convenient operation and maintenance, and brick adobe The effect of high volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

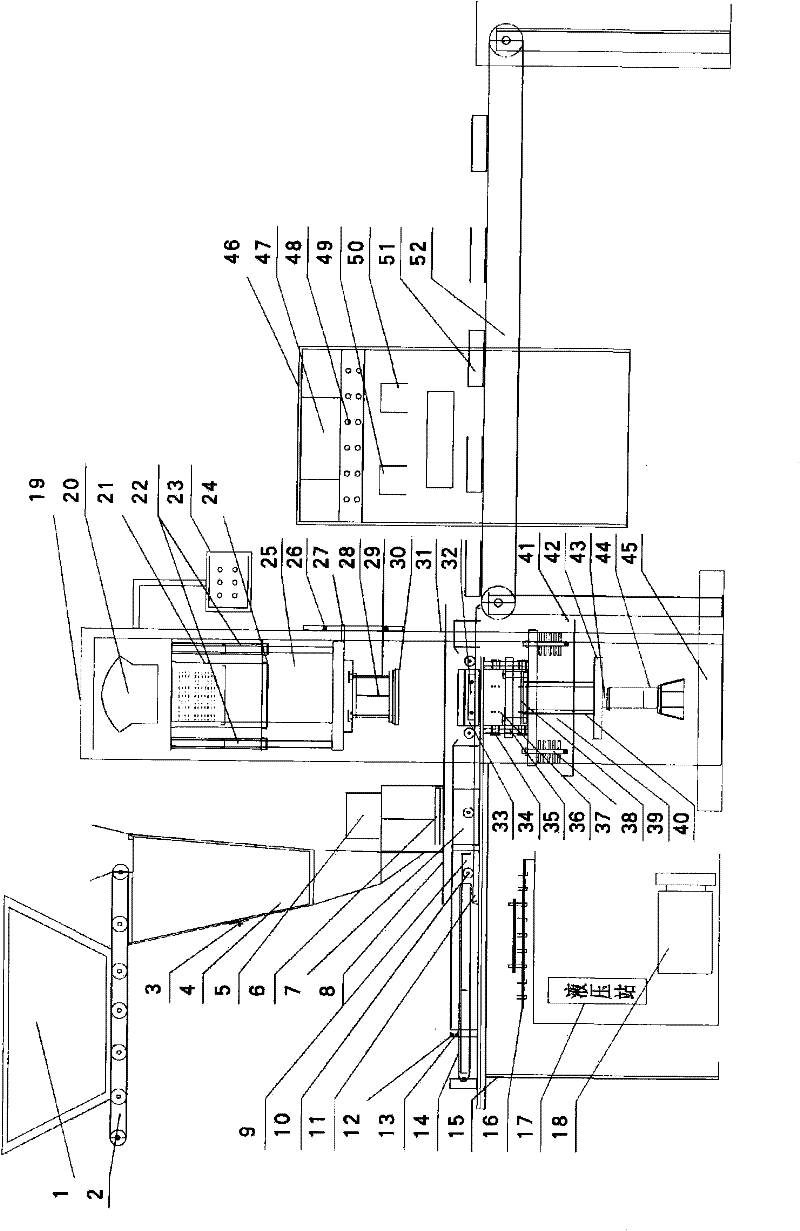

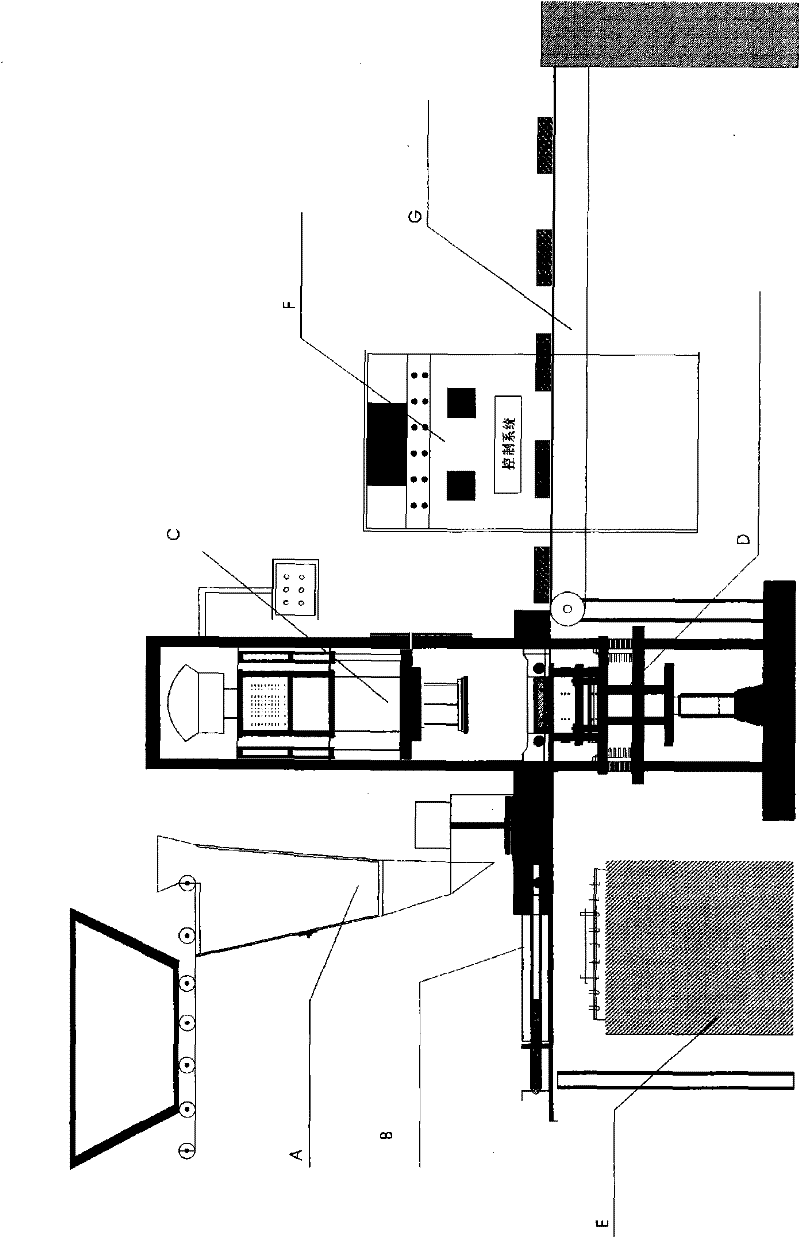

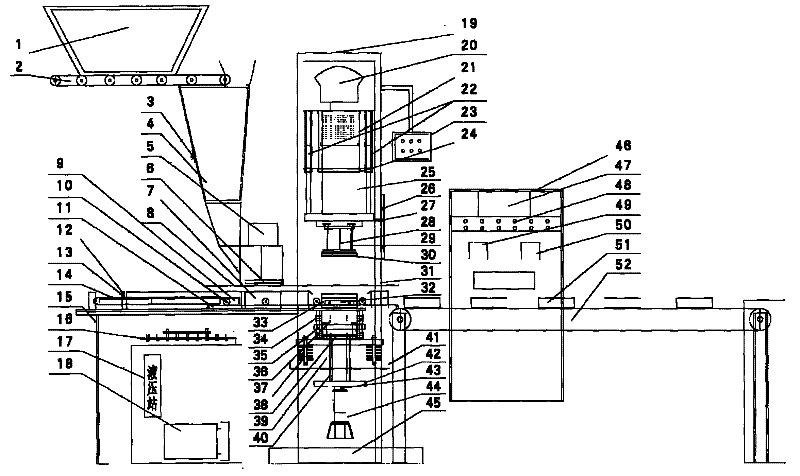

[0011] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0012] Such as figure 2 Shown: A fully automatic hydraulic press is mainly composed of automatic feeding part A, intelligent robot cloth and built-in manipulator clamping part B, pressing part C, product ejection device part D, power part E, conveying part F and control part G structure, through the set sensor, the sensor sends the collected signal to the control part, the central processor of the control part processes the feedback signal to make a judgment and sends an instruction to each terminal, and the automatic feeding part completes the feeding action and then the The intelligent robot carries out the cloth, and presses and forms with the elastic method of double-side pressure. While pressing and forming, the automatic feeding part enters the next feeding cycle. After the product is formed, the product is released through the product ejection device, and is clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com