Production method of steel plastic concrete composite wound pipe

A technology for winding pipes and production methods, applied in chemical instruments and methods, mixed operation control, mixed operation control devices, etc., can solve the problems of insufficient rigidity, poor bending resistance, and narrow application range, and achieves strong integrity, High bending and impact resistance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Production method of solid-wall circular steel strip steel-plastic concrete composite winding pipe

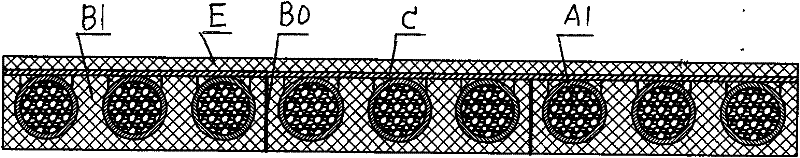

[0035] 1. Firstly produce the rolled cross-section such as Figure 4 The three-slot solid-walled plastic plate shown with B1.

[0036] 2. Use spiral winding equipment to wind the three-slot solid-wall plastic strip B1 and bond the side walls B0 of the plastic strip B1 to each other to form the inner wall of the pipe.

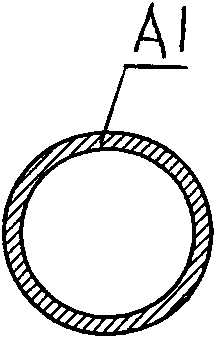

[0037] 3. Wind three circular steel strips A1 at the same time and insert them into three arc-shaped slots of plastic strip B1 respectively. When the winding and embedding length of the steel strip A1 reaches the set length of each section of the pipe, the steel strip A1 and the plastic strip B1 are cut into sections together with a cutting machine.

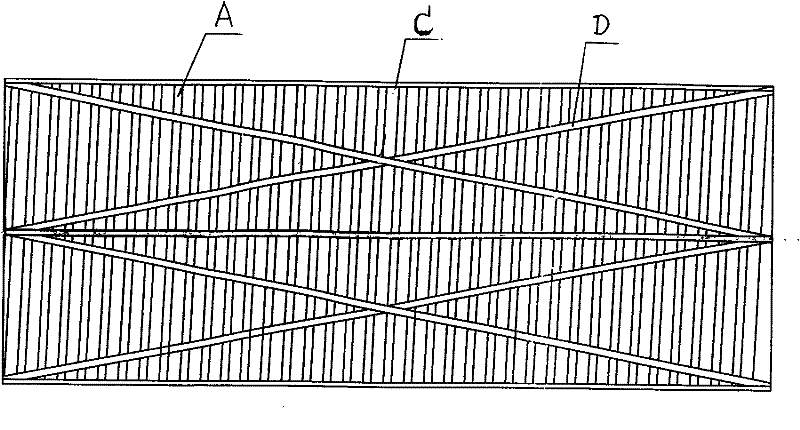

[0038] 4. Fix more than 4 axially parallel steel strips C that are parallel to each other and evenly distributed on the steel strip A1 that has formed a spiral shape. The intersection of the ax...

Embodiment 2

[0042] Example 2 Production Method of Single Hollow Square Steel Strip Steel-Plastic Concrete Composite Winding Pipe

[0043] 1. Firstly produce the rolled cross-section such as Figure 8 Double slot single hollow plastic plate shown with B2.

[0044] 2. Use spiral winding equipment to wind the double-groove single hollow plastic strip B2 and bond the side walls B0 of the plastic strip B2 to each other to form the inner wall of the pipe.

[0045] 3. Wrap two square steel strips A2 at the same time and embed them in the two arc-shaped slots of the plastic strip B2, and cut them into strips when they reach the set length.

[0046] 4. Fix more than 4 axially parallel steel strips C on the steel strip A2 that has formed a spiral shape. The intersection of the axially parallel steel strips C and each steel strip circle is welded by spot welding, and two oblique steel strips are welded together. Both ends of strip D are respectively cross-welded on the outer ends of every two adja...

Embodiment 3

[0051] Example 3 Production Method of Double Hollow Special-shaped Steel Strip Steel-Plastic Concrete Composite Winding Pipe

[0052] 1. Firstly produce the rolled cross-section such as Figure 12 The hollow plastic plate is shown with B3.

[0053] 2. Use spiral winding equipment to wind the double hollow plastic strips B3 and bond the side walls B0 of the plastic strips B3 to each other to form the inner wall of the pipe.

[0054] 3. Wind the special-shaped steel strip A3 and embed it in the slot in the middle of the plastic strip B3, and cut it into knots when it reaches the set length.

[0055] 4. Fix more than 4 axially parallel steel strips C on the steel strip A3 that has formed a spiral shape. The two ends of the steel bar D are respectively cross-welded on the outer ends of every two adjacent axially parallel steel bars C, that is, the oblique steel bars D are used to cross-connect the axially parallel steel bars to form mesh steel bars.

[0056] 5. Cover plastic on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com