Device for installing carton handles

A carton handle and equipment technology is applied in the field of equipment that automatically installs the carton handle on the box body, which can solve the problems of inability to meet the hygienic requirements of food packaging, injury to workers' fingers, and easy contamination of the carton, and achieve reasonable and smooth internal logistics. , The effect of improving the sanitary conditions of the carton and reducing the installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

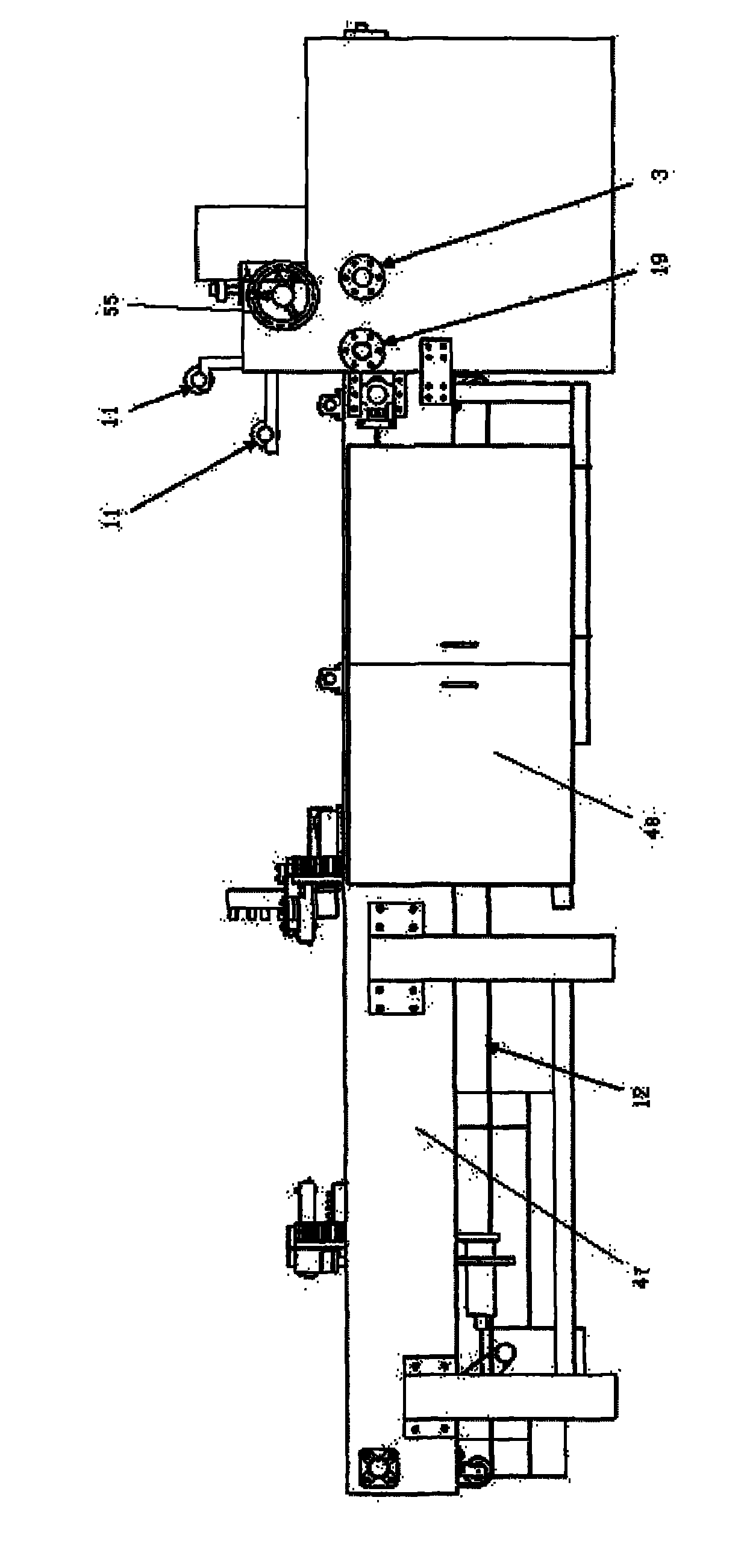

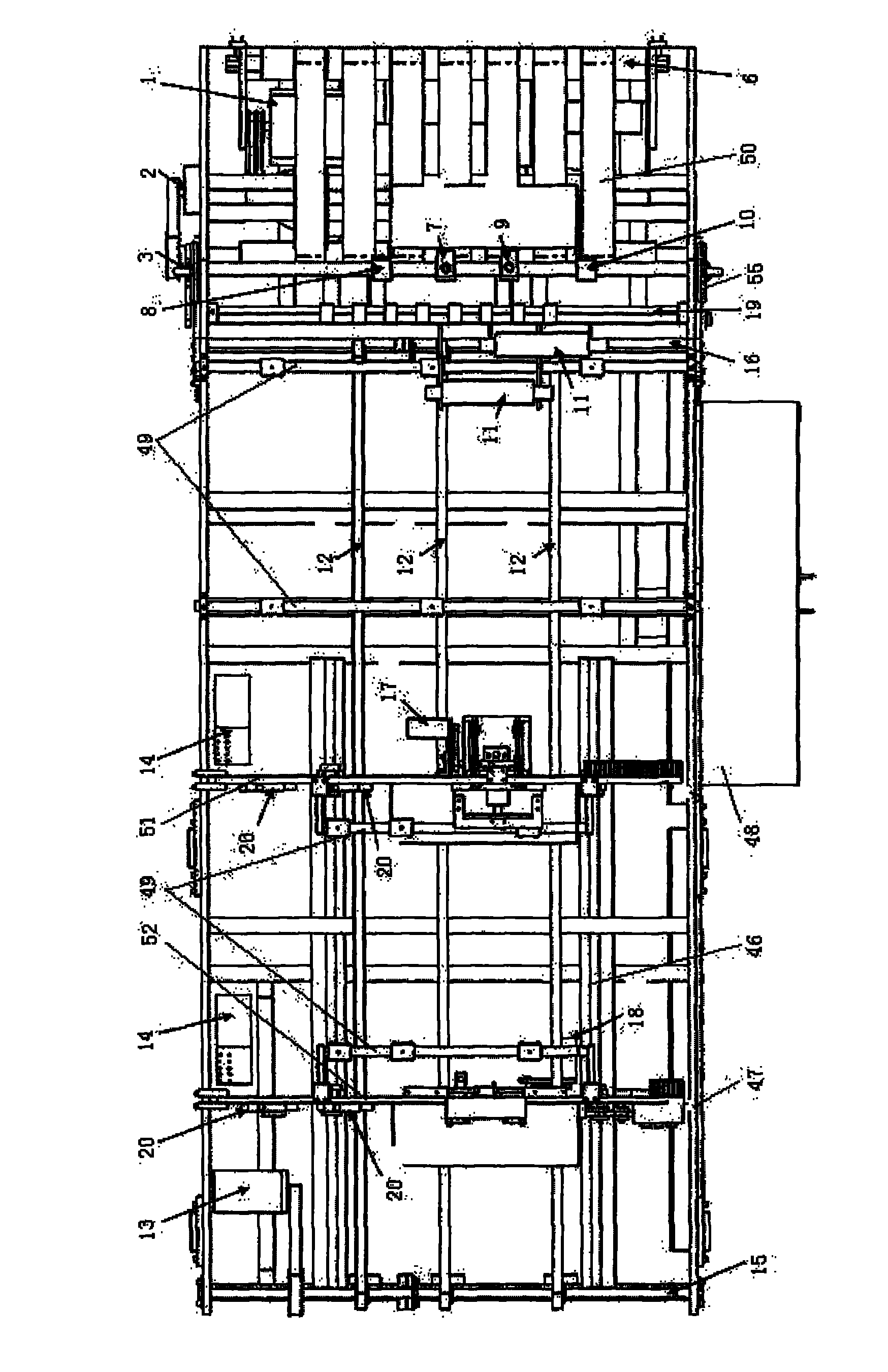

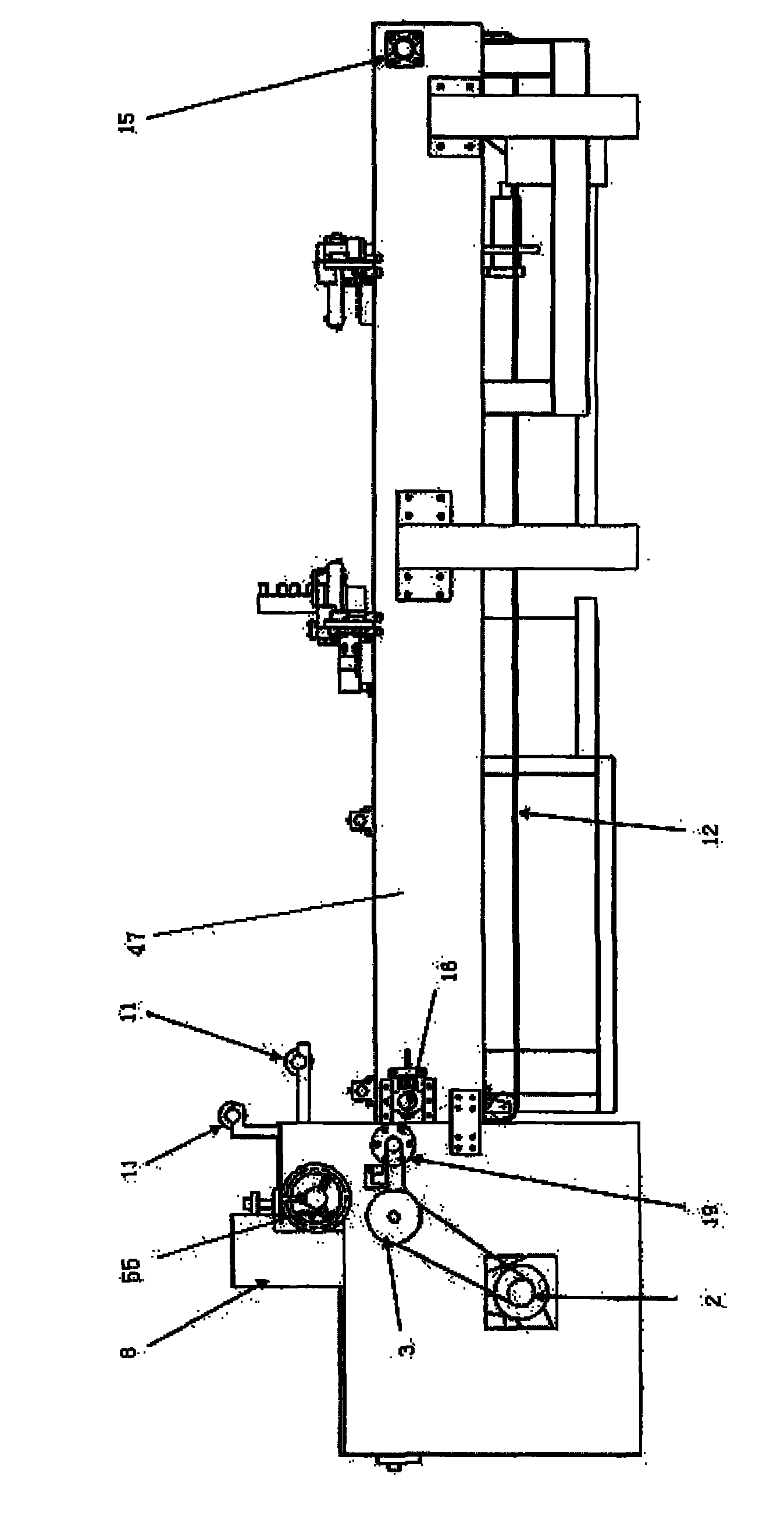

[0025] Part numbers in the figure: paper feeding motor 1; clutch 2; paper feeding belt drive shaft 3; suction fan 4; suction box 5; paper feeding belt driven shaft 6; right front baffle 7; right side baffle 8; left front baffle 9 ; Left baffle plate 10; Reinforced belt reel 11; Chain 12; Chain main drive servo motor 13; Solenoid valve fixed seat 14; Chain driving shaft 15; Chain driven shaft 16; ; Divider shaft 19; Vacuum generator 20; Punching cylinder 21; Reinforced belt heat sealing cylinder 22; Reinforced belt heating block 23; Punching bottom mold 24; Punching knife 25; Switch 27; reinforced belt feeding driven wheel 28; reinforced belt feeding driving wheel 29; reinforced belt heat sealing cylinder support 30; reinforced belt cutter 31; handle belt threading cylinder 32; handle belt heat sealing cylinder 33; handle belt Preheating block 34; handle belt heating block 35; handle belt clamping cylinder 36; handle belt feeding drive wheel 37; handle belt feeding driven wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com