Preparation methods of porous far-infrared ceramic material and two-layer far-infrared ceramic plate

A kind of far-infrared ceramics and far-infrared technology, which is applied to ceramic products, other household utensils, household utensils, etc., and can solve the problems of poor plasticity, easy bursting, and easy weathering of blanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] (1) Add brass powder with a mass percentage of 5-30% of the mass of the raw material to the raw material with far-infrared function, ball mill the mixture mixed with the brass powder, and mix it uniformly. (2) Add the coke powder screened to the mixture obtained in step (1) with a mass percentage of 5-30% of the mass of the mixture, and then mix evenly. (3) The binder polyvinyl alcohol is dissolved in water, the addition of polyvinyl alcohol accounts for 1~20% of the mass percentage composition of water, then puts a small amount of guiding agent Glauber's salt into the polyvinyl alcohol aqueous solution, stirs 1 ~2 hours. (4) Put the mixture obtained in the step (2) into the solution obtained in the step (3), and the plasticity of the clay after refining and stale is very good. The prepared mud is pressed or molded into various shapes, and then dried. (5) Putting the blank obtained in step (4) into a tunnel kiln for firing at a firing temperature of 1200-1400° C. and ...

example 2

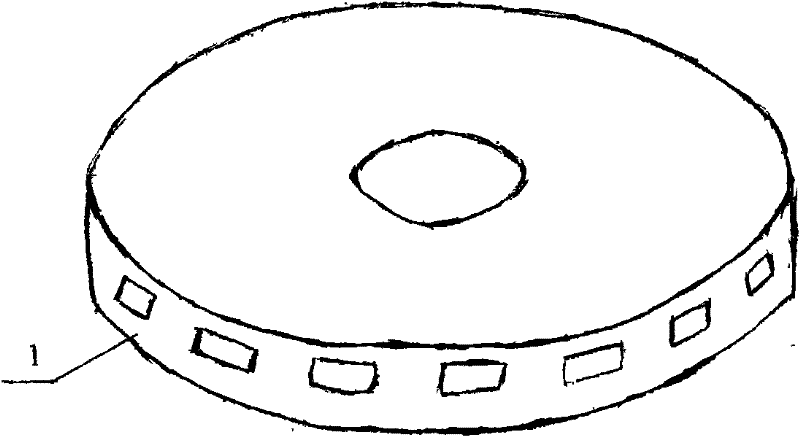

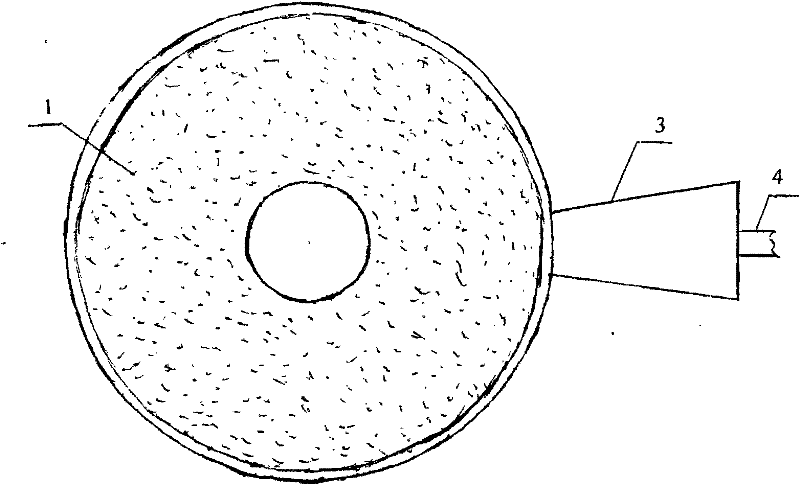

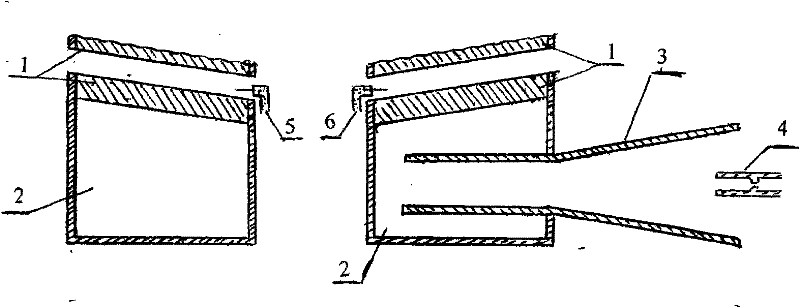

[0016] The preparation method of double-layer far-infrared ceramic plate 1 of the present invention, concrete steps are as follows: 1) add mass percent content to the raw material with far-infrared function and account for 5~30% brass powder of raw material quality, will be mixed with brass powder The mixture was ball milled and mixed evenly. 2) To the mixture obtained in step 1), add the coke powder pore-forming agent that has been screened and whose mass percentage accounts for 5-30% of the mixture mass, and then mix evenly. 3) Use water-soluble mirabilite as a guide agent, use viscous water-soluble polyvinyl alcohol as a binder, and dissolve polyvinyl alcohol in water. The amount of polyvinyl alcohol added accounts for the mass of water. 1-20% of the percentage content, then put a small amount of Glauber's salt into the above solution, and stir for 1-2 hours. 4) Put the mixture obtained in step 1) into the solution obtained in step 3), and after smelting and aging, press i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap