Large-diameter hollow hydraulic oscillatory motor

A hydraulic swing and large-diameter technology, which is applied in the field of drive components and large-diameter hollow hydraulic swing motors, can solve problems such as unsatisfactory, limited pre-tightening force, and easy deformation of the shaft, so as to reduce frictional interference torque, enhance anti-deformation ability, The effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

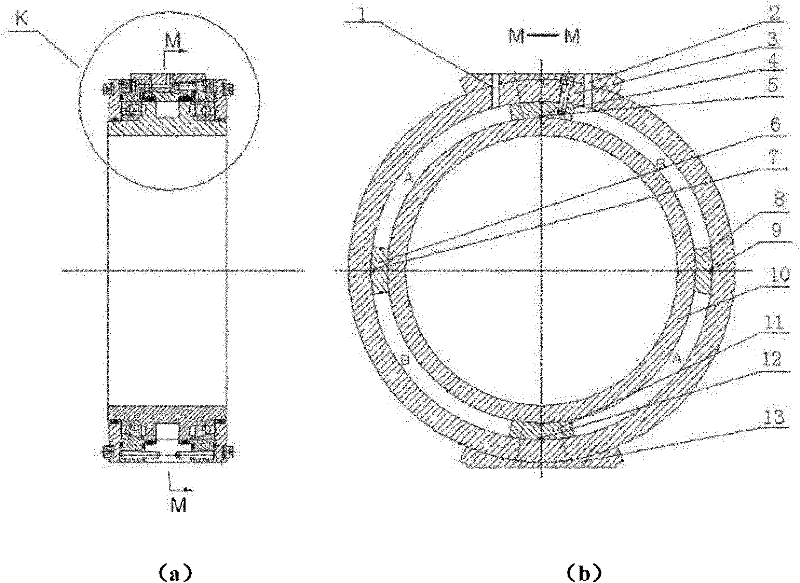

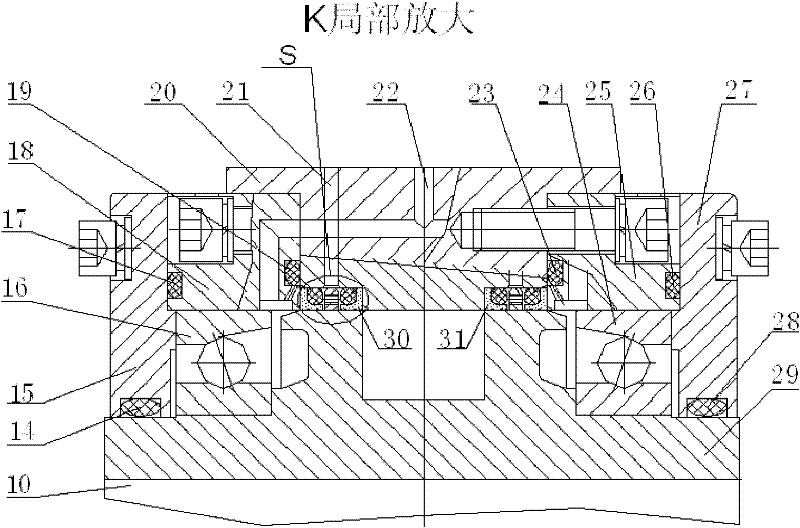

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following the described embodiment.

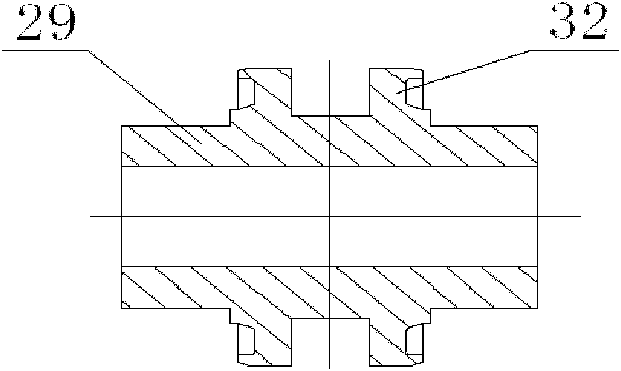

[0023] like figure 1 and figure 2 As shown, this embodiment includes: a hollow rotor 10, a motor housing assembly 3, a left end cover 15, a right end cover 27, a first seal 17, a second seal 26, a third seal 14, a fourth seal 28, The first thrust bearing 16, the second thrust bearing 24, and the base 13, wherein: the hollow rotor 10 is installed in the motor housing assembly 3, and the left end cover 15 and the right end cover 27 are fixed on the motor housing assembly 3 with screws respectively. On the left bearing seat 18 and the right bearing seat 25, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com