Image-identification-based system for detecting contour dimension of motor vehicle

A technology of motor vehicle and external dimensions, which is applied in the field of detection system of motor vehicle external dimensions, which can solve the problems of low image stability, influence on the accuracy of detection results, and large area occupied by equipment, so as to achieve simple and convenient maintenance and maintenance of equipment, Improve the efficiency of detection operation and occupy a small area of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

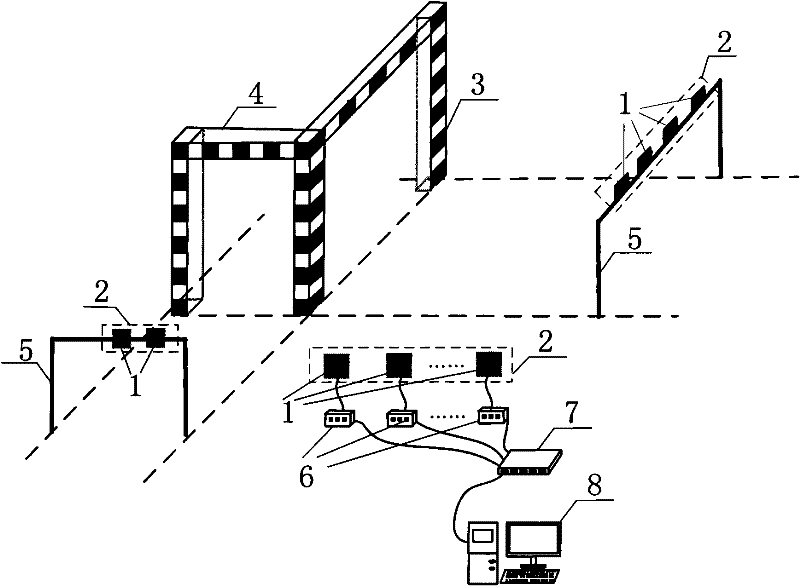

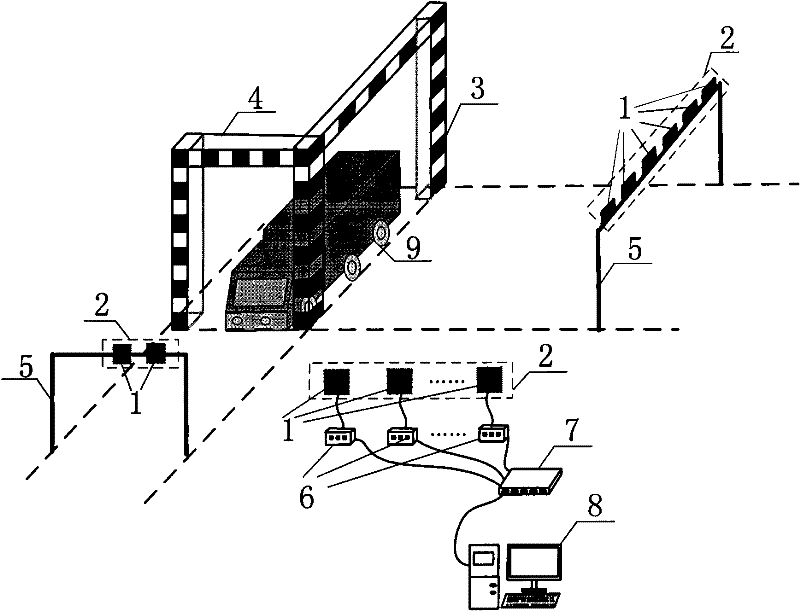

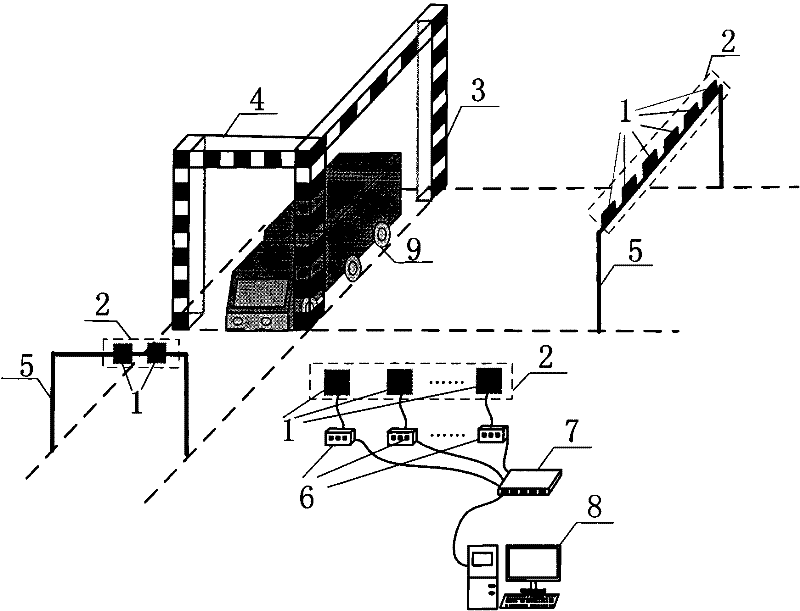

[0014] combined with figure 1 , the specific embodiment of the present invention is as follows: the present invention is mainly composed of digital camera group (2), black and white barcode ruler (3), double gantry frame (4), single gantry frame (5), front-end control device (6), switch (7) and computer (8). The double-gantry frame (4) is a right-angled double-facade frame, and its specification and size can be determined according to the external dimensions of the motor vehicle to be tested. Generally, the façade size of the front façade is selected as: height×length=5×5m, side façade The size of the facade is: height * length = 5 * 18m is good; the black and white bar code ruler (3) equal to its size is arranged on the double gantry (4) outer side frame, and each black and white bar code ruler (3) in the black and white bar code ruler (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com