Corrosion test accelerating device

A technology of accelerated corrosion test and test box, applied in the direction of testing wear resistance, etc., can solve the problems of large occupied space and low experimental efficiency, and achieve the effect of small occupied space, compact testing device and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The novel accelerated corrosion test device of the present invention will be further described below in conjunction with the accompanying drawings.

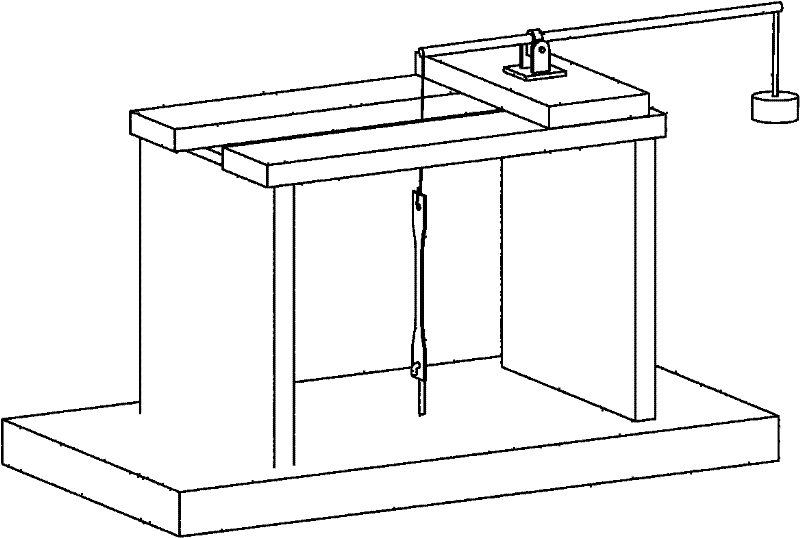

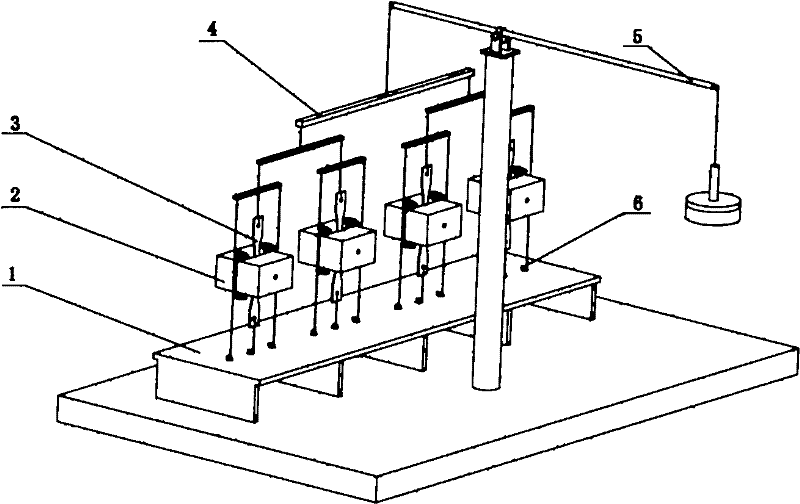

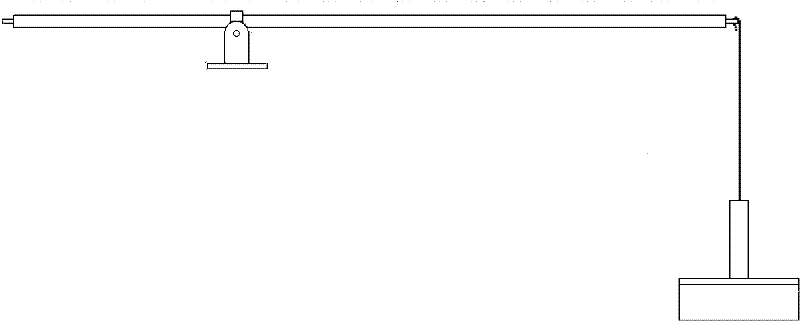

[0017] figure 2 It is a three-dimensional schematic diagram of the accelerated corrosion test device of the present invention, referring to figure 2 As shown, the accelerated corrosion test device includes a fixed bearing platform 1, a corrosion environment test box 2, a graded loading system 4, and a lever loading system 5. image 3 It is the schematic diagram of the lever loading system of the accelerated corrosion test device of the present invention, referring to image 3 As shown, one end of the lever of the lever loading system 5 is connected to the weight, and the other end is connected to the highest level in the hierarchical loading system 4. The fulcrum of the lever loading system is fixed on the ground through a column, and the fulcrum can be adjusted along the direction of the lever to enlarge or reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com