Flexible-substrate-based solid super capacitor and manufacturing method thereof

A technology for supercapacitors and flexible substrates, which is applied to capacitor parts and other directions, and can solve problems such as heavy weight and difficult substrate bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

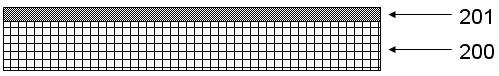

[0030] Step 1: Please refer to figure 1 , the flexible substrate 200 is put into an electron beam evaporation system or a magnetron sputtering system to deposit a layer of adhesive 201, wherein 200 is polytetrafluoroethylene (Teflon), and the thickness is 200 microns; 201 is titanium, and the thickness is 200 μm. 1 to 10 nanometers.

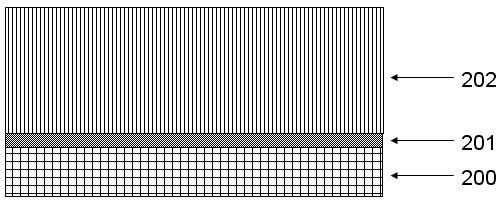

[0031] Step 2: Please refer to figure 2 , deposit a layer of metal 202 (with a purity of 99.99%) on the surface of 201 through an electron beam evaporation system, wherein 202 is aluminum with a thickness of 1-2 microns.

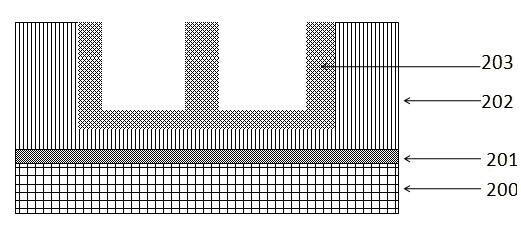

[0032] Step 3: Please refer to image 3 , 203 is obtained by traditional two-time anodizing on 202, of which 203 is alumina. Here, the process conditions of the two anodizing processes are the same, both using a concentration of 0.3M and a temperature of 0 o C sulfuric acid solution, app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com