Preparation method for whole pumpkin powder

A technology for pumpkin whole powder and pumpkin, which is applied to the field of preparation of pumpkin whole powder, can solve the problems of incomplete processing of pumpkin residue and the like, and achieve the effects of complete and reasonable pipeline production, significant economic benefits and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0026] Embodiment 1: new The fresh pumpkin is made of Guangxi Miben pumpkin.

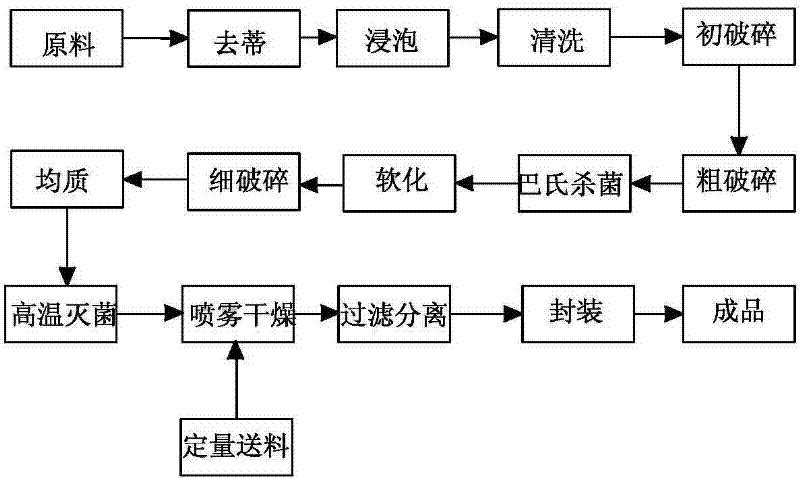

[0027] Referring to Fig. 1~5, the technological process of the preparation method of pumpkin whole powder is: fresh whole pumpkin is selected, destemmed, soaked, cleaned, primary crushing, coarse crushing, softening and pasteurization, fine crushing, homogenization, high temperature instant Sterilization, spray drying, quantitative feeding, filtration and separation, and packaging of finished products.

[0028] The specific process flow is:

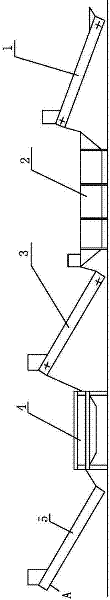

[0029] Soaking and cleaning steps: Fresh unpeeled pumpkins are selected by the conveyor 1, the stalks are removed, sent to the continuous soaking machine 2 for soaking for about 30 minutes, and then sent to the roller brush cleaning machine 4 connected to the conveyor 3 for rinsing in normal temperature water On the surface of the pumpkin, the number of miscellaneous bacteria in the pumpkin after cleaning can be increased from 10 8 down to lO 5 piece / g;

...

Embodiment 2

[0044] Example 2: The raw material of fresh pumpkin is Hunan Miben pumpkin.

[0045] Adopt the process steps of Example 1, remove the stalks, wash, soak for 30 minutes at a temperature of 10°C, and crush the whole pumpkin into 2-3 mm granular pumpkins. The primary crusher crushes the granular pumpkins into a paste of 0.3-0.5 mm. Soften and pasteurize at 87°C for 30 minutes. Grind the pasteurized 0.3-0.5mm granular pumpkin into a paste of 0.15-0.25mm in a conical mill, homogeneously emulsify, and sterilize instantly at high temperature 135°C, time 60 seconds, spray drying, separation of fibrous matter, qualified pumpkin powder packaging finished product.

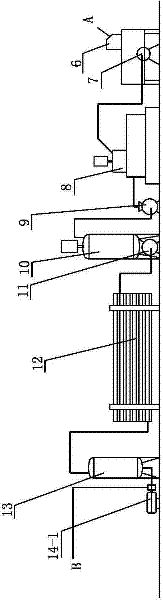

[0046] The upper part of the spray drying main tower 24 is a straight cylinder, the lower part is a cone, the inner diameter of the tower is Φ7800mm, the height of the straight tower is 7000mm, the slurry processing capacity is 1800kg / h, the air inlet temperature is 215-225°C, and the air outlet temperature is 80-90°C. The...

Embodiment 3

[0048] Example 3: The raw material of fresh pumpkin is Hubei Miben pumpkin.

[0049] Adopt the process steps of Example 1, remove the stalks, wash, soak for 30 minutes at a temperature of 10°C, and crush the whole pumpkin into 2-3mm granular pumpkins, and the primary crusher crushes the granular pumpkins into 0.3-0.5mm paste, Soften and pasteurize at 90°C for 30 minutes. Grind the pasteurized 0.3-0.5 mm granular pumpkin into a 0.15-0.25 mm gelatin containing pumpkin seed skin in a conical mill, homogeneously emulsify , high-temperature instantaneous sterilization at 135°C for 60 seconds, spray drying, separation of fibrous matter, and qualified pumpkin powder packaging finished product.

[0050] The upper part of the spray drying main tower 24 is a straight cylinder, the lower part is a cone, the inner diameter of the tower is Φ7800mm, the height of the straight tower is 7000mm, the slurry processing capacity is 1300kg / h, the inlet air temperature is 200-210℃, the outlet air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com