Vertical sliding compression mechanism in sliding compression continuous solid-liquid separator

A technology of a solid-liquid separator and a pressurizing mechanism, which is applied in the field of pressurizing mechanisms, can solve problems such as increased production costs, difficulty in pressing, and small footprint, so as to meet the requirements of reducing the site, enhance adaptability, and reduce the footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

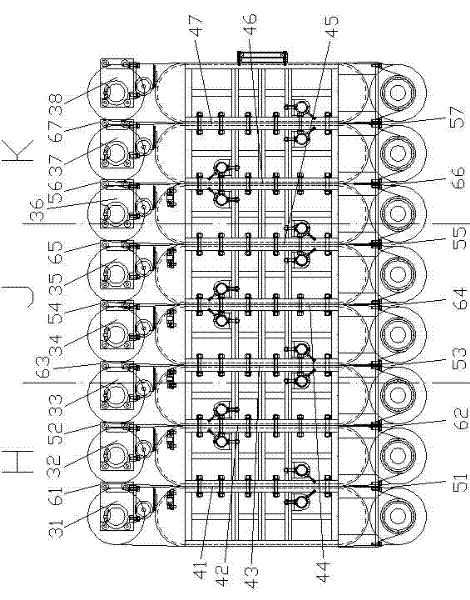

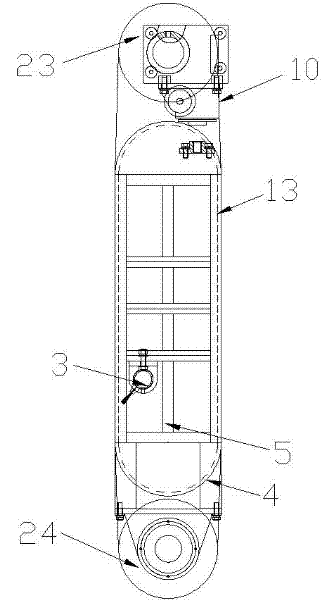

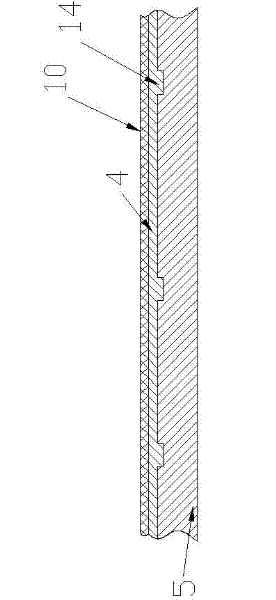

[0045] see Figure 1 to Figure 14 , the vertical sliding pressurization mechanism in the sliding pressurization continuous solid-liquid separator in the present embodiment comprises eight side-by-side pressing units 22, and these eight side-by-side pressing units 22 are No. 1 pressing unit 31 from left to right , No. 2 press unit 32, No. 3 press unit 33, No. 4 press unit 34, No. 5 press unit 35, No. 6 press unit 36, No. 7 press unit 37 and No. 8 press unit 38, and eight press units 22 are Vertical structure, the number of squeezing units 22 in the present invention can be set according to actual needs, as can be determined according to the nature of the material to be squeezed, the desired squeezing effect, etc., the number of squeezing units 22 in the present invention is usually Between 4-20, of course, the number of pressing units 22 is less than four or more than twenty. Since the vertical sliding pressurization mechanism in this embodiment is made up of eight squeeze uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com