Vertical roll membrane filtering device and cleaning method thereof

A filter device and roll-type membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high cleaning frequency, short life, incomplete cleaning, etc., to extend the service life and be widely used , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

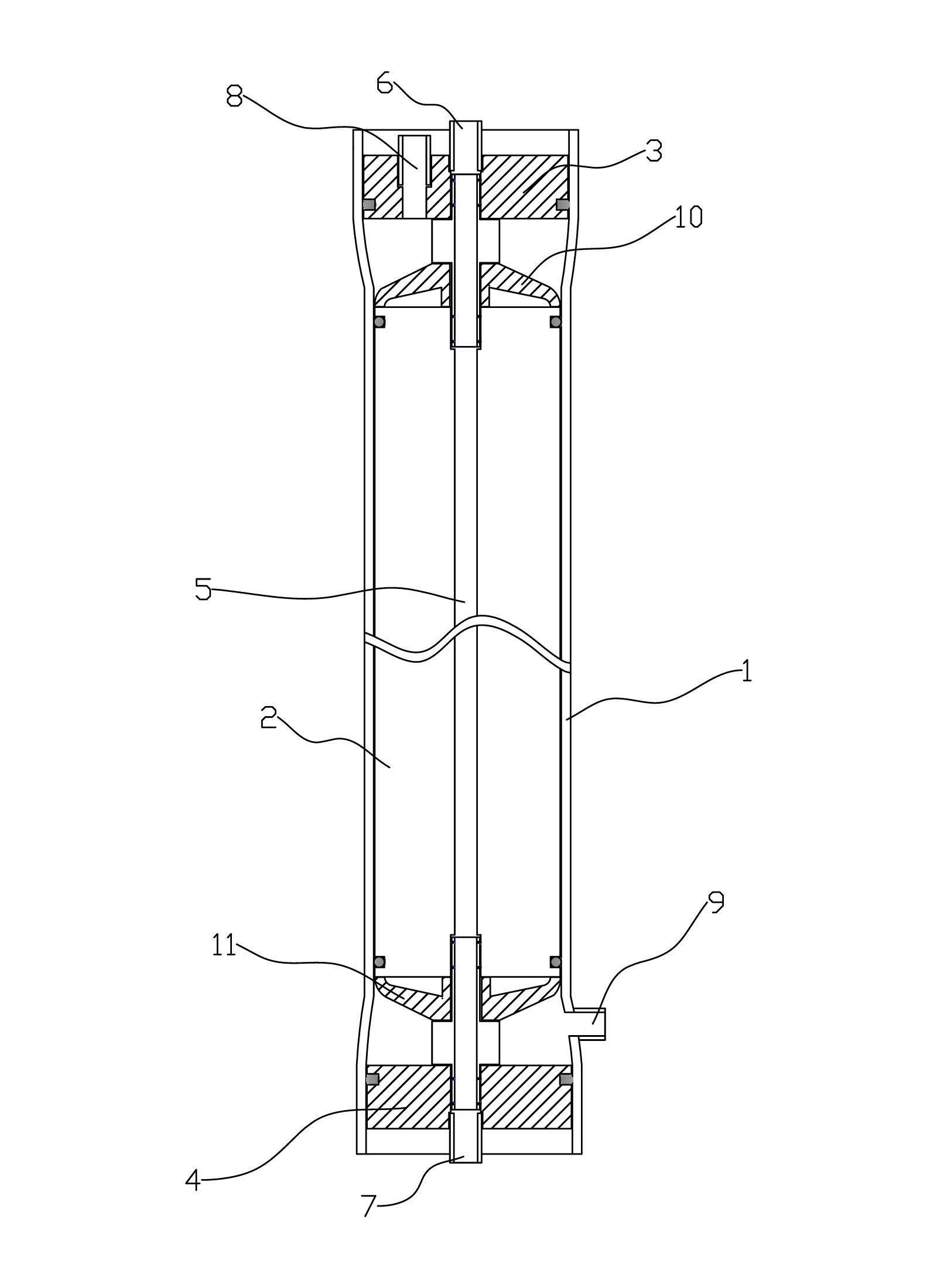

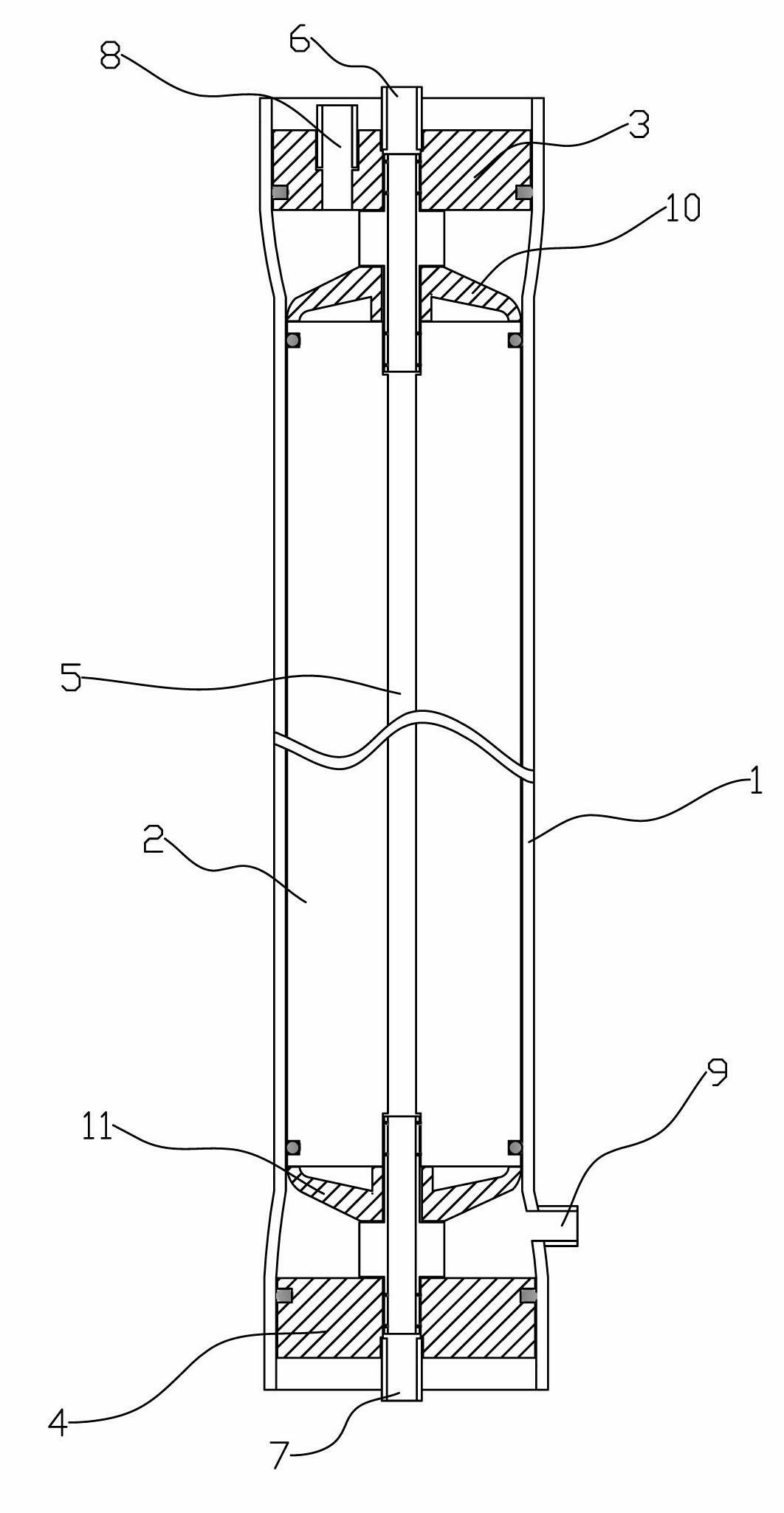

[0029] refer to figure 1 , a vertical roll-type membrane filtration device of the present invention includes a vertically placed membrane housing 1, a roll-type membrane element 2 adapted to it is installed in the membrane housing 1, and the upper and lower ends of the membrane housing 1 are respectively installed There are upper and lower sealing heads 3, 4, and the roll-type membrane element 2 has a permeate output pipe 5, and the two ends of the permeate output pipe 5 are provided with a pipe extending through the upper and lower sealing heads 3, 4 respectively. The upper and lower permeate outlets 6, 7 of the membrane housing 1 are respectively provided with upper and lower water flow openings 8, 9. During filtration, the raw water enters the membrane casing 1 from the lower water flow opening 9, and partly flows out from the upper water flow opening 8 after cutting through a group of membrane elements. The re-entry permeate output pipe 5 is the permeate, and the permeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com