Off-line washing and repairing device for multifunctional waste reverse osmosis membrane

A reverse osmosis membrane, off-line technology, used in semi-permeable membrane separation, reverse osmosis, membranes, etc., can solve the problems of affecting the cleaning effect, complicated operation, and inaccurate data comparison, and achieve obvious cleaning effect and high repair efficiency. , test the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of single-membrane RO pure water:

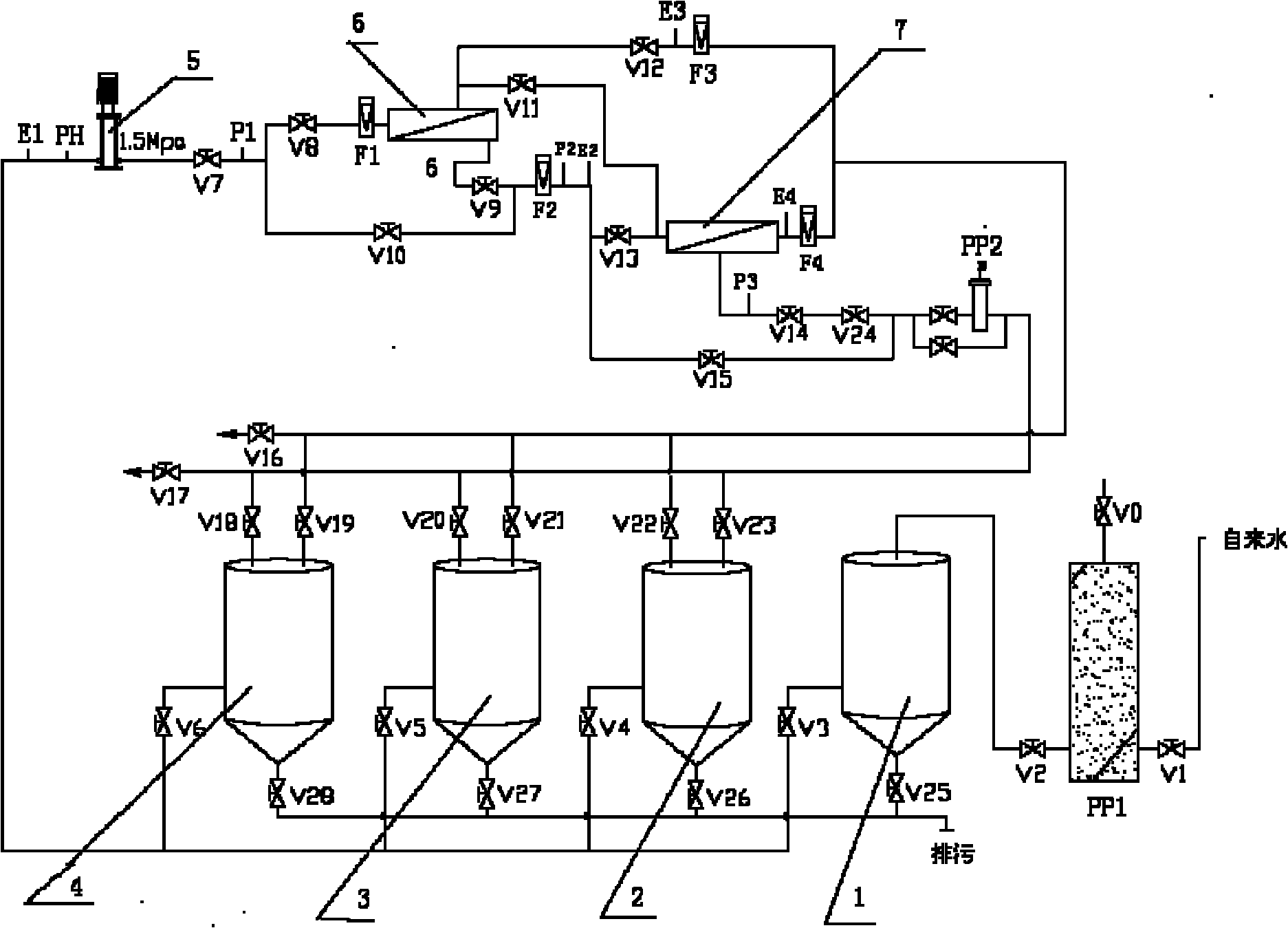

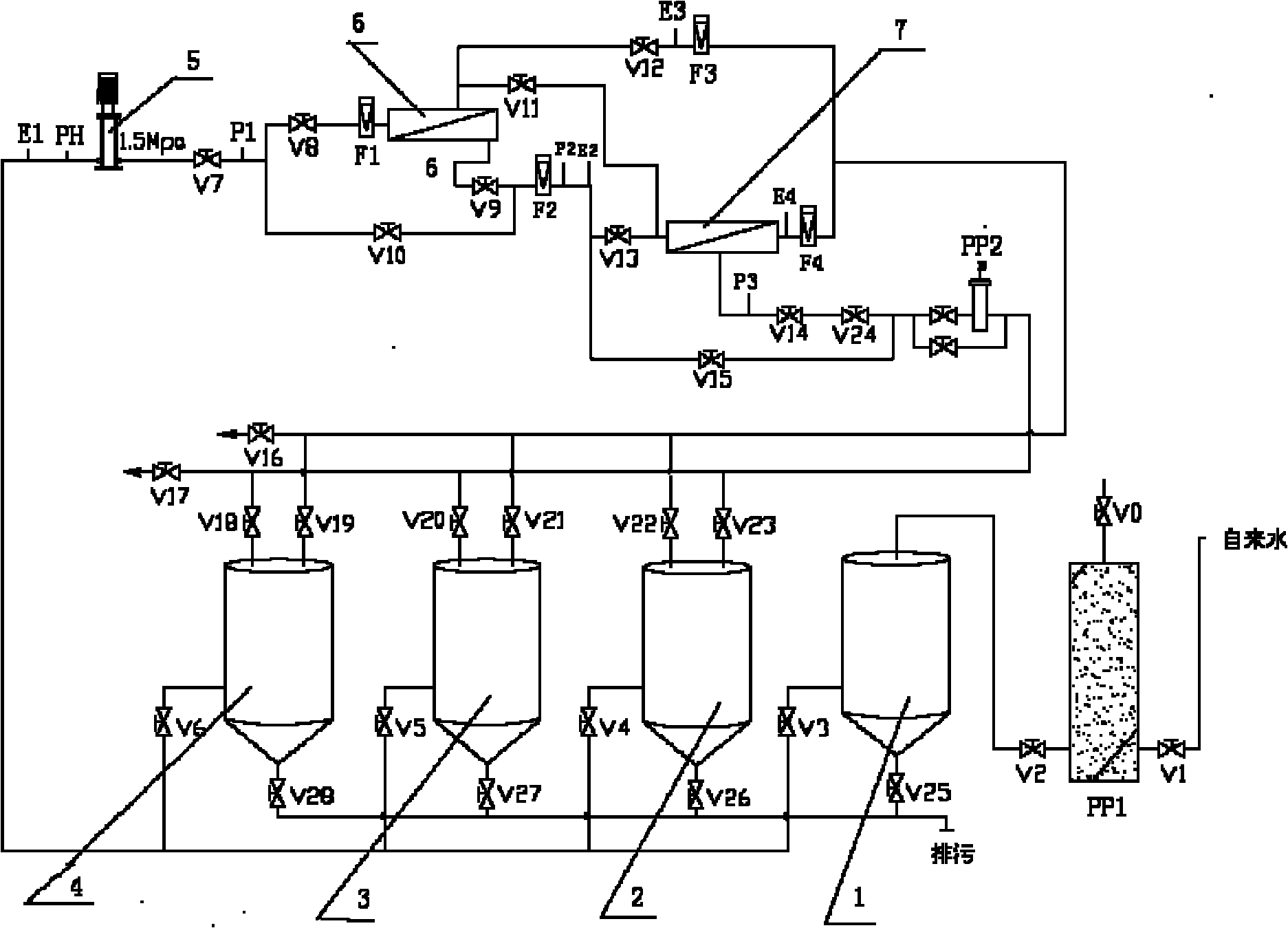

[0036] An off-line cleaning and repairing equipment for multifunctional waste reverse osmosis membranes. The structural composition and connection relationship of the equipment are as follows:

[0037] Structural composition and its connection relationship:

[0038] The equipment is mainly composed of valves, flowmeters, conductivity meters, pressure gauges, inlet water pH meters, booster pumps P and precision filters PP1 and PP2. The valves are composed of filter element emptying valve V0, tap water valve V1, tap water Inlet valve V2, tap water outlet valve V3, acidic lotion inlet valve V4, alkaline lotion inlet valve V5, restoration agent water inlet valve V6, main water inlet valve V7, old membrane inlet valve V8, old membrane concentrated water Outlet valve V9, old membrane short-circuit valve V10, pure water-new membrane inlet valve V11, old membrane fresh water outlet valve V12, new membrane inlet valv...

Embodiment 2

[0042] Embodiment 2: Preparation of double-membrane RO pure water

[0043] An off-line cleaning and repairing equipment for multifunctional waste reverse osmosis membranes (the structural composition and connection relationship are the same as those in Example 1).

[0044] method:

[0045] Open the tap water valves V1, V2, fill the tap water bucket with tap water filtered by the 5μm PP1 filter element, open V3, V7, V8, V9, V15, V11, V14, V24, V17, V16, and close the other valves; turn on the power and start Booster pump 5, using two membranes in series to produce RO pure water, when the reading of E4 is less than 2μs / cm, turn on V23, V21, V19 in turn, and inject RO pure water into pickling tank 2, alkali cleaning tank 3, repair agent Box 4.

Embodiment 3

[0046] Embodiment 3: single-membrane acidic chemical agent cleaning waste RO membrane

[0047] An off-line cleaning and repairing equipment for multifunctional waste reverse osmosis membranes (the structural composition and connection relationship are the same as those in Example 1).

[0048] method:

[0049] Prepare an acid cleaning agent with a total volume of 150L in the pickling tank 2, open V4, V7, V8, V9, V15, V22, V12, V23, and close all other valves; turn on the power, start the booster pump 5, and pass through V9 Adjust the pickling flow rate, and use an acid cleaning agent to clean a single waste RO membrane 6 in a circular manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com