Full-automatic pot cleaning machine controlled by computer

A computer-controlled, fully automatic technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low work efficiency, leakage of cleaning, high layout density, etc., to improve the cleaning effect and efficiency. , Improve the cleaning quality, the effect of cleaning the fouling and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

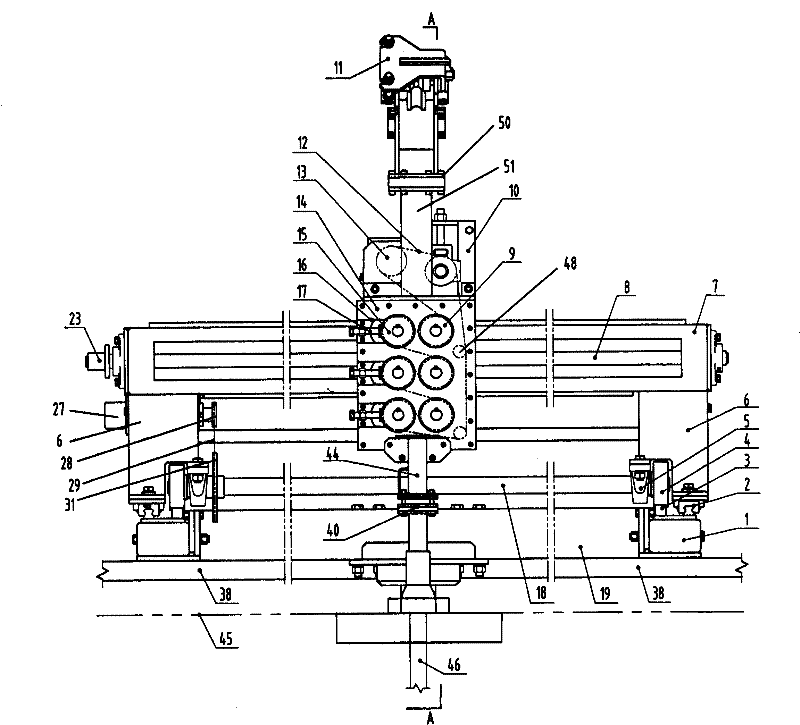

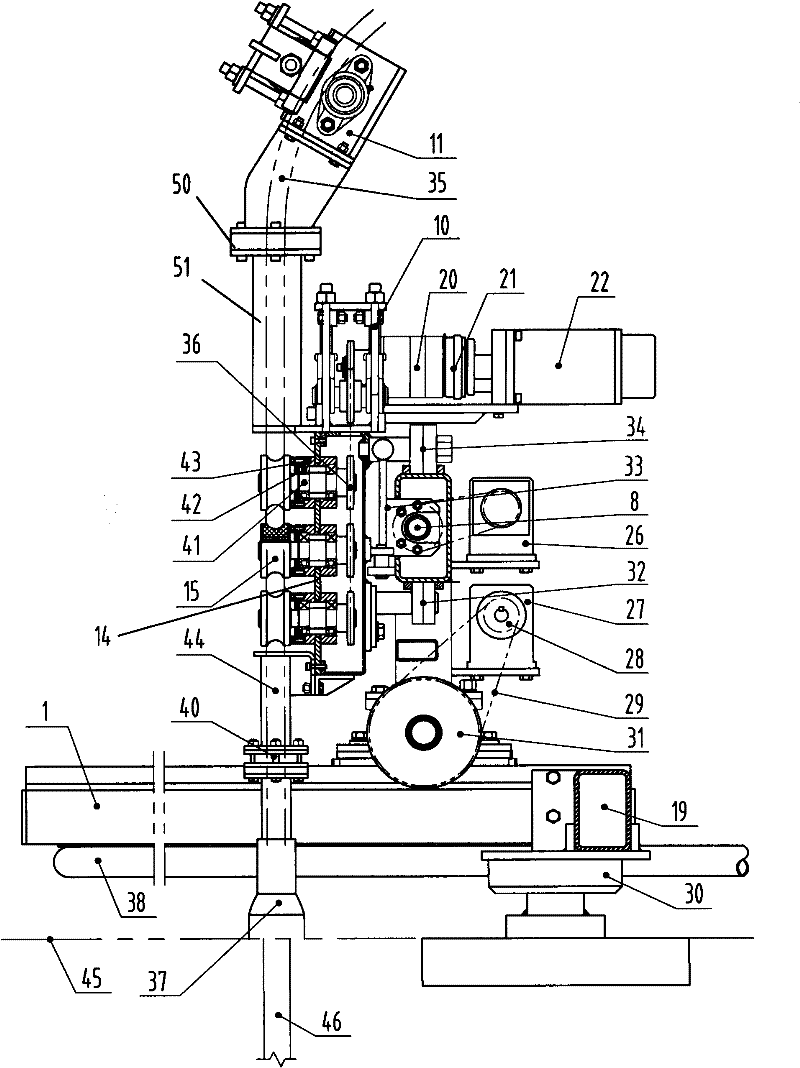

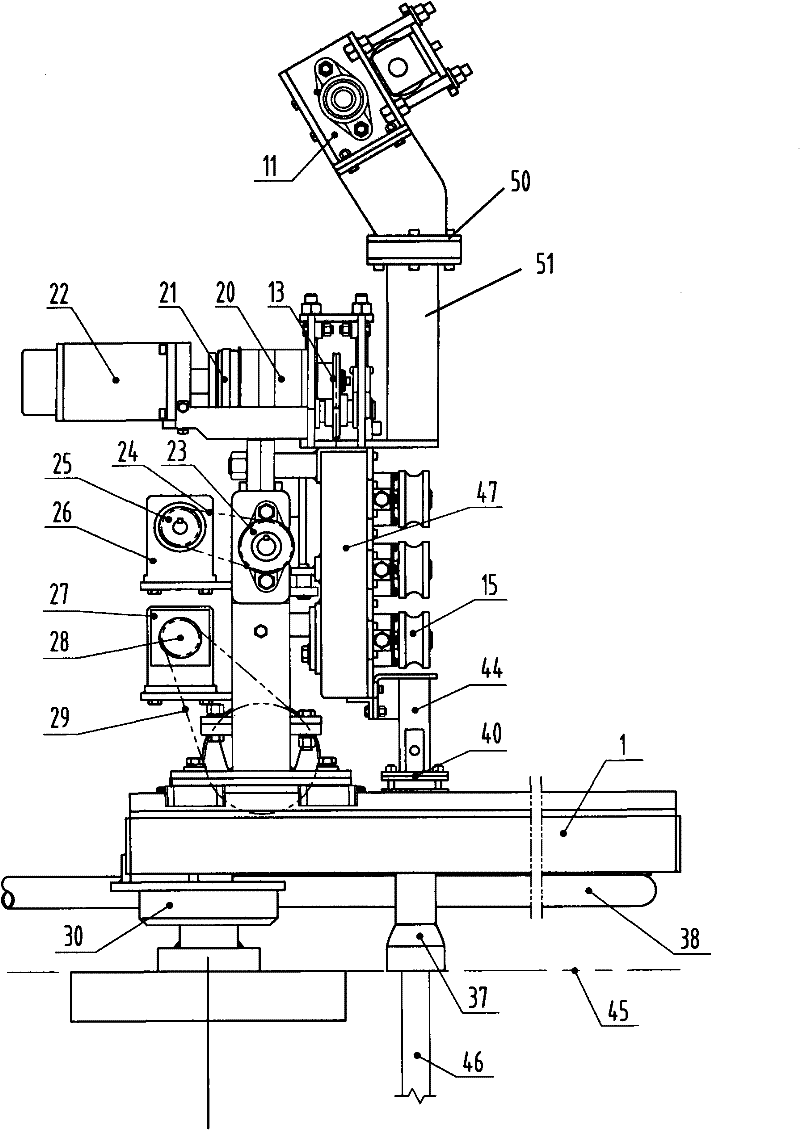

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

[0029] The computer-controlled fully automatic can opening machine of the present invention includes an X-axis assembly 7, two Y-axis assemblies 1 that are parallel to each other and perpendicular to the X-axis assembly 7, and a driving device assembly 47.

[0030] On the outer edge of the evaporator flower plate 45, a circular guide rail 38 is solidly welded, and the center of the evaporator flower plate 45 is installed with a central rotating assembly 30, which is connected to the cross bar 19, and the cross bar 19 passes through the central rotating assembly 30 can be used for 360 ° rotation, between the two ends of the cross bar 19 and the circular guide rail 38, two Y-axis assemblies 1 parallel to each other are installed and fixed with bolts, so that the two Y-axis assemblies 1 can be mounted with the evaporator flower plate 45 The center is the center of circle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com