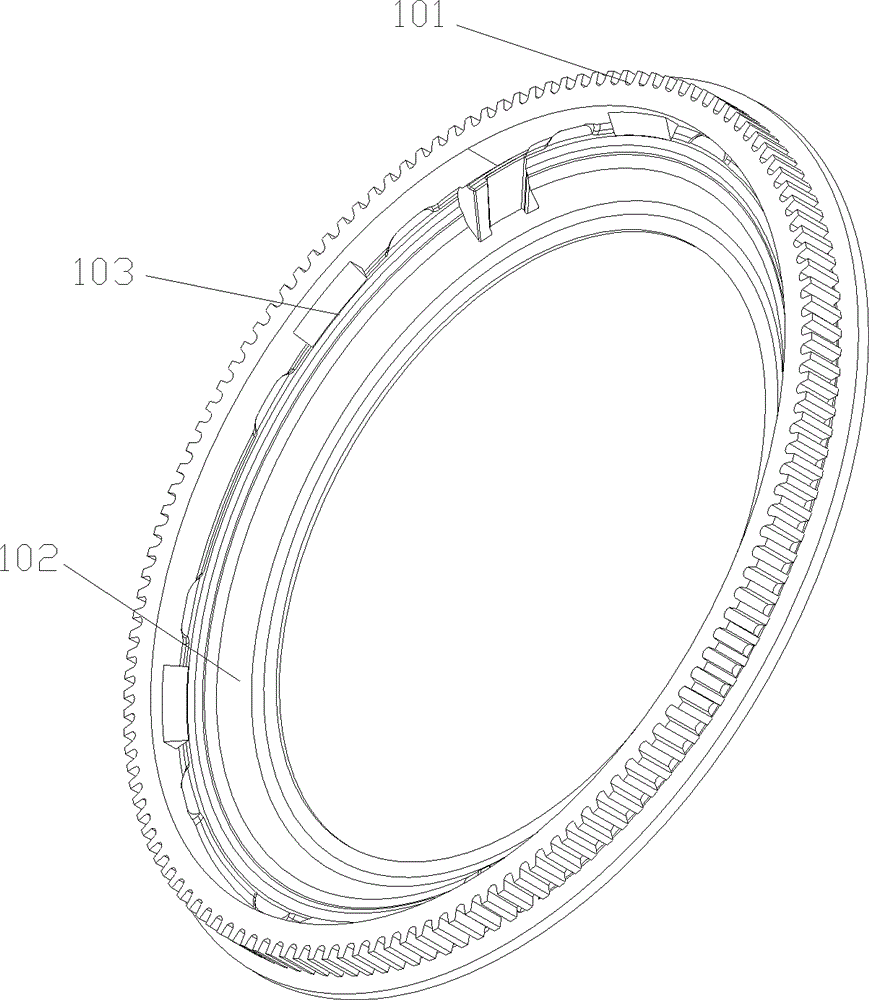

Welding method of automobile brake gear ring and device using method

A technology for automobile braking and welding devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of uneven welding angle height, deviation of welding seam position, large deformation of gear ring, etc., and achieve reasonable welding sequence. , The effect of preventing welding deformation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

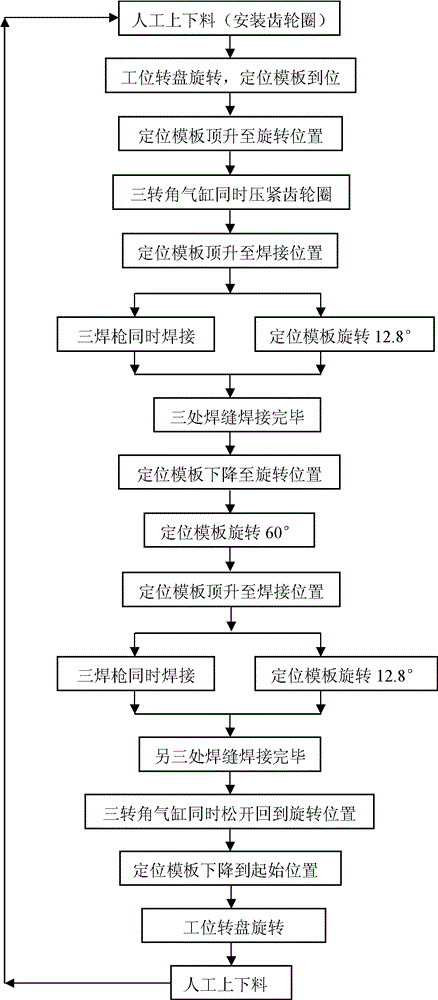

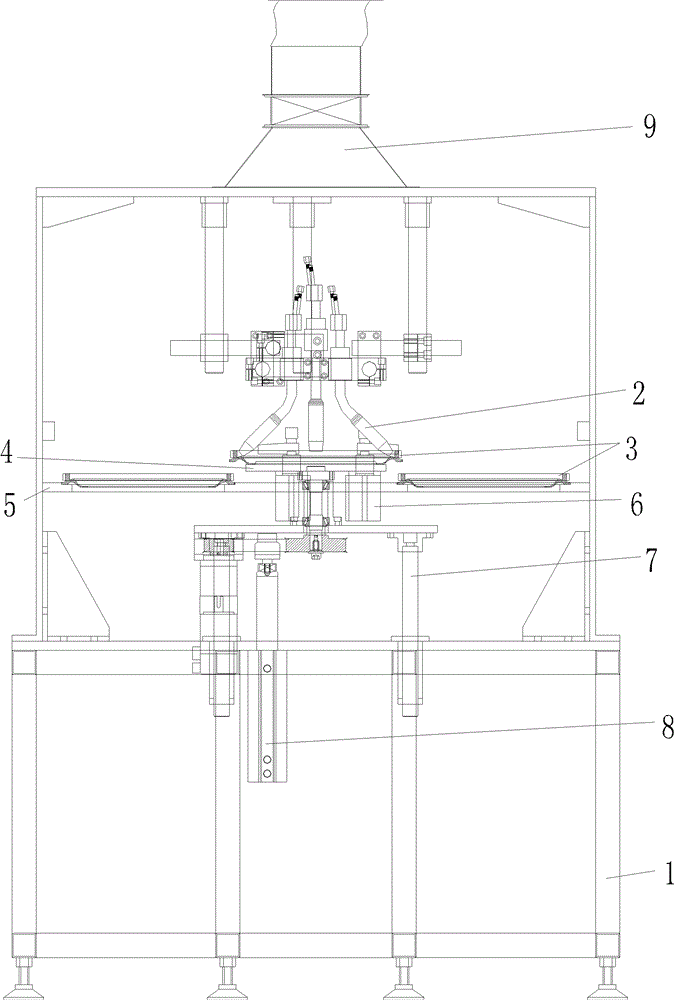

[0038] like figure 2 Shown, a kind of automobile brake gear ring welding method comprises the following steps:

[0039] A) Manual loading and unloading, place the car brake gear ring (including the ring gear and cover plate) on the corresponding positioning hole of the station turntable, the station turntable rotates, driving the gear ring to rotate to the welding station, at this time, the positioning template In the starting position, the positioning template is located directly below the positioning hole, that is, directly below the welding torch, and the size of the positioning template matches the size of the positioning hole, that is, the positioning template can pass through the positioning hole;

[0040] B) The positioning template rises to the rotating position through the jacking cylinder. At this time, the gear ring is also located on the positioning template, and the gear ring is driven by the positioning template to rise to the rotating position together; at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com