Integrated building-block-type lift of strip steel structure

A steel structure, building block technology, applied in the field of mechanical lifting, can solve the problems of unreliability, uneconomical, long construction period, etc., and achieve the effect of reducing the area occupied, reducing the working strength and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

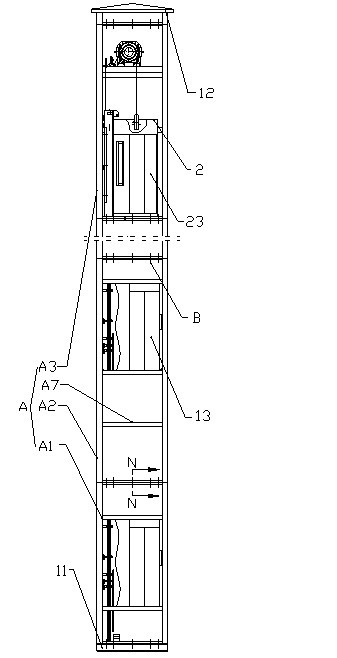

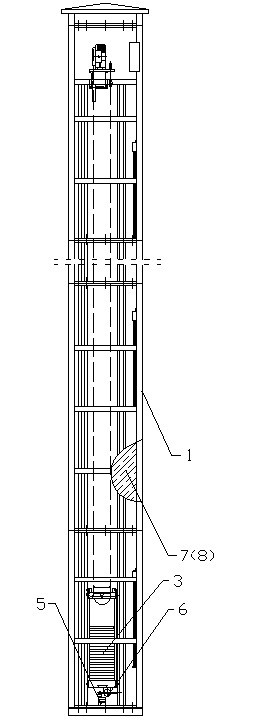

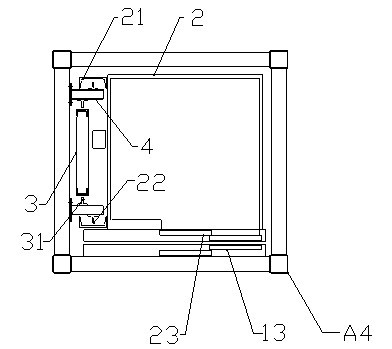

[0016] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

[0017] Referring to the legend, an elevator with integrated building blocks with steel structure includes a rectangular steel structure shaft 1, and the rectangular steel structure shaft 1 is provided with a liftable rectangular car 2 and a pair of doors on the outside of the side wall of the rectangular car 2. The heavy device 3 is characterized in that: the rectangular steel structure shaft 1 includes a base 11, and the base 11 is sequentially provided with a bottom frame A1, at least one middle layer frame A2, a top frame A3 and a top cover 12 from bottom to top ; The corresponding side wall of the rectangular steel structure shaft 1 is provided with a pair of guide rail brackets 4 positioned on both sides of the counterweight device 3, and the inner ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com