Composite oil displacement agent

A technology for compound flooding and chemical compounds, applied in drilling compositions, chemical instruments and methods, etc., can solve problems of stability, viscosity reduction, viscosity loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

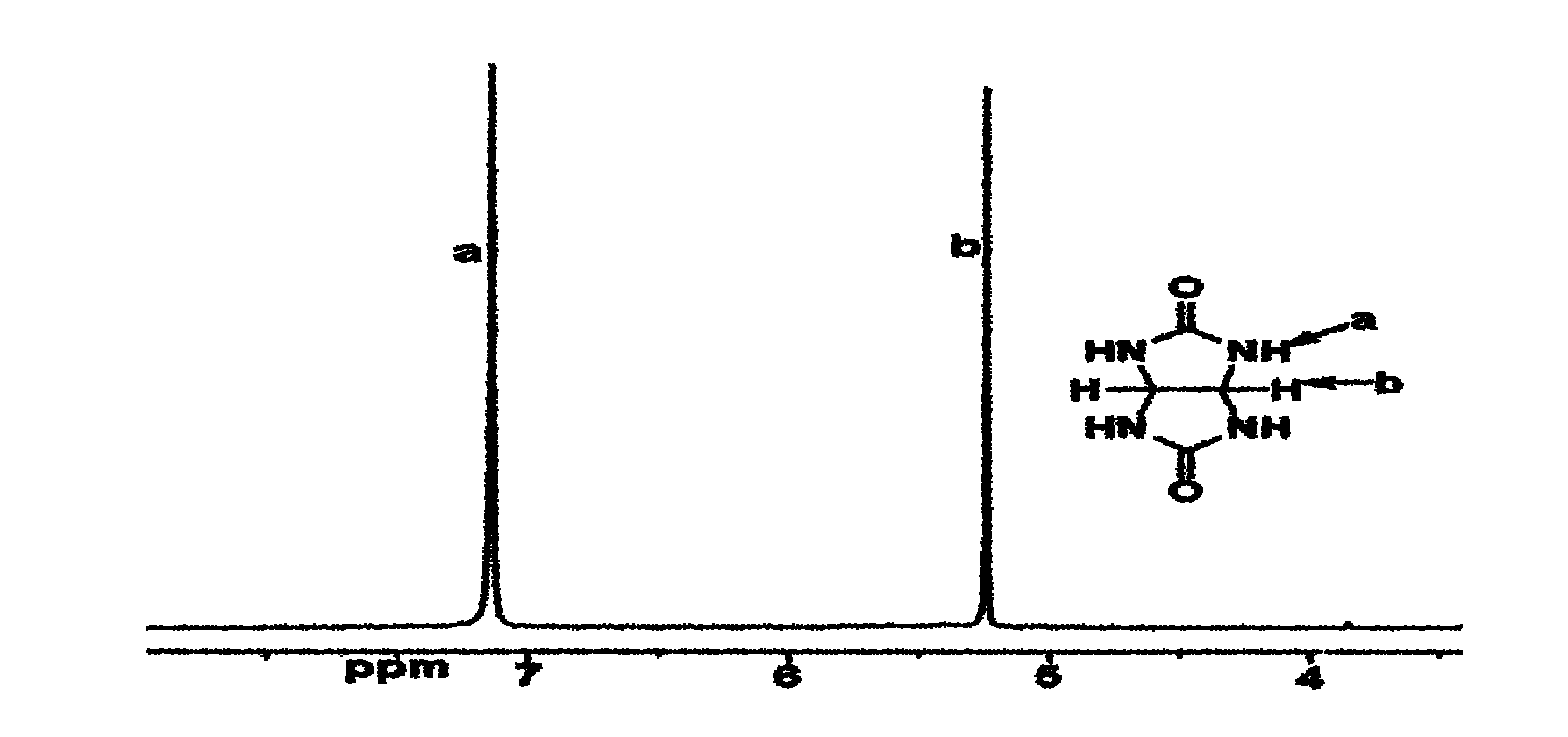

[0017] Embodiment 1, the preparation of composite oil displacement agent

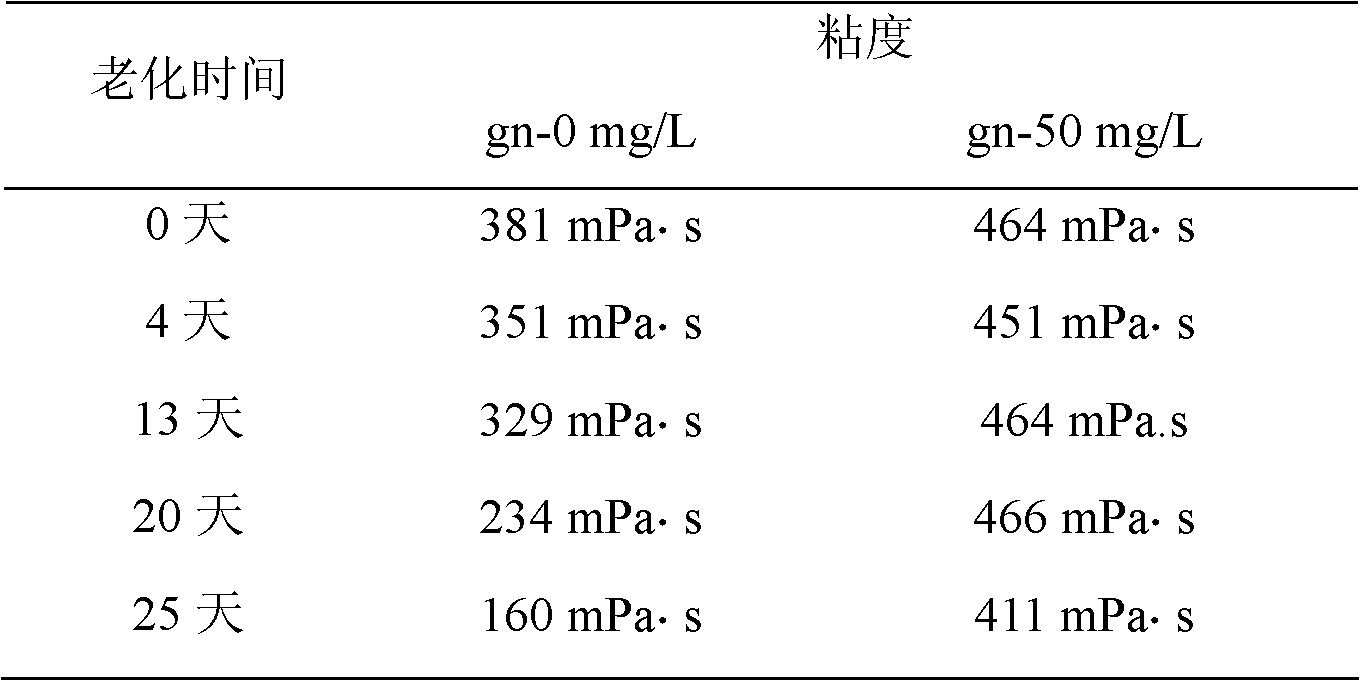

[0018] Weigh 0.025g of the above-mentioned prepared glycoluril (abbreviated as gn) and add to 8074mg / L mineralized water containing 500mL (composed of 6408.4mg / L NaCl, 30.37mg / L KCl, 419mg / L CaCl 2 , 324.6mg / L MgCl 2 , 36.98mg / LNa 2 SO 4 , 84.8mg / L Na 2 CO 3 , 769.8mg / L NaHCO 3 and the balance is water), stir until completely dissolved, then weigh 0.875g AP-P4 dry powder and slowly add it to the above-mentioned simulated mineralized water containing glycoluril, stir until completely dissolved to obtain a composite oil displacement agent, wherein, glycoluril The mass volume concentration of AP-P4 is 50mg / L, and the mass volume concentration of AP-P4 is 1750mg / L.

[0019] The obtained composite oil displacement agent was sheared for 20 seconds with the first gear of the WARING agitator to simulate the state of the composite oil displacement agent after the surface injection process and the strong me...

Embodiment 2

[0020] Embodiment 2, the preparation of composite oil displacement agent

[0021] The preparation process is the same as in Example 1, except that the quality of glycoluril (abbreviated as gn) is changed to 0.05g. The mass volume concentration of glycoluril in the prepared composite oil displacement agent was 100 mg / L, and the mass volume concentration of AP-P4 was 1750 mg / L.

[0022] The obtained composite oil displacement agent was sheared for 20 seconds with the first gear of the WARING agitator to simulate the state of the composite oil displacement agent after the surface injection process and the strong mechanical shearing of the bottom hole through the blast hole, and then bubbled with nitrogen and sealed for storage. Yes, then place the composite oil displacement agent in a constant temperature incubator at 65°C for aging, and measure it with a Brookfield DVII viscometer at a shear rate of 7.34S -1 1. The test temperature is the viscosity of the composite oil displace...

Embodiment 3

[0023] Embodiment 3, the preparation of composite oil displacement agent

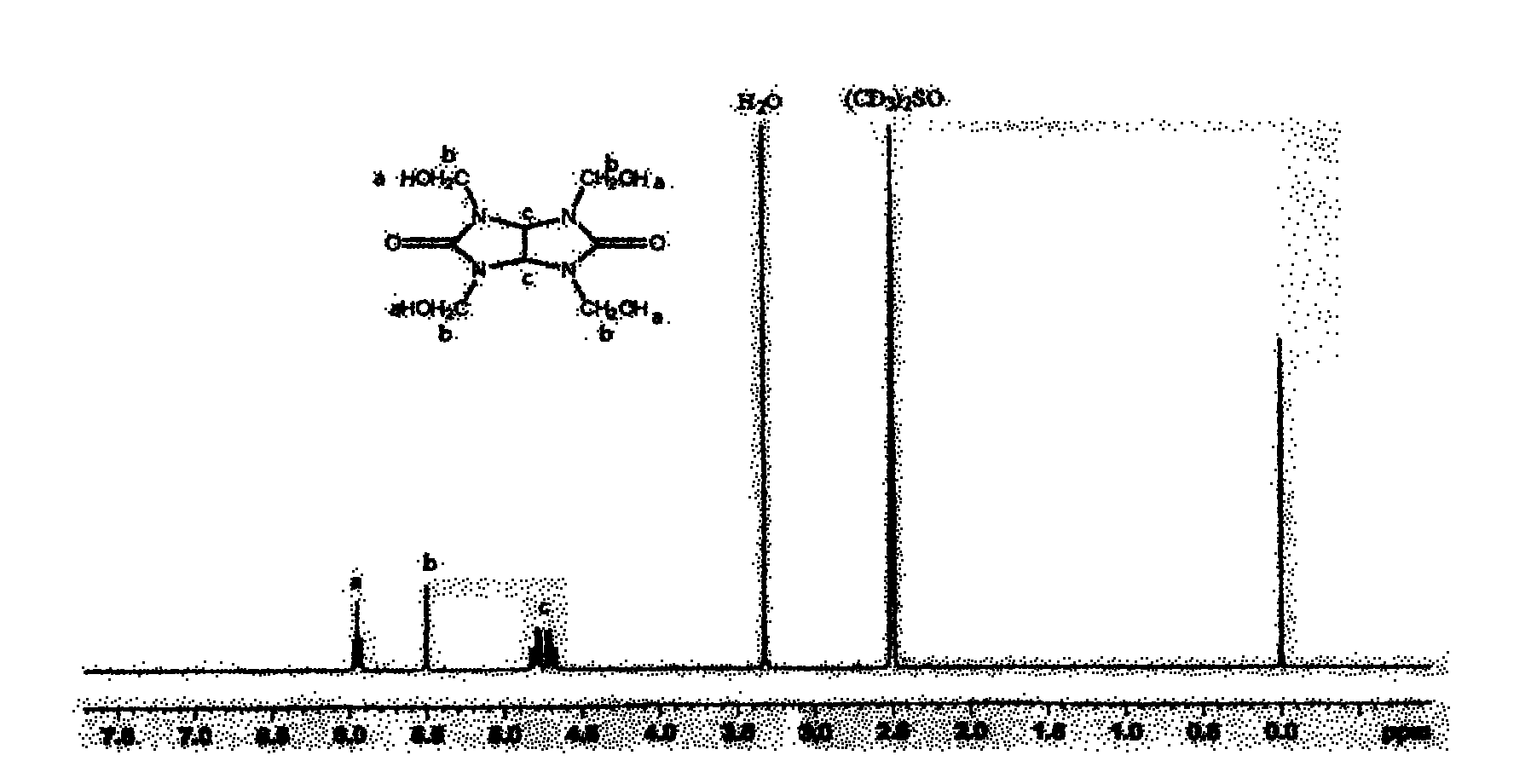

[0024] Weigh 0.025g of tetramethylol glycoluril (abbreviated as sgn) prepared above and add to 8074mg / L mineralized water containing 500mL (composed of 6408.4mg / L NaCl, 30.37mg / L KCl, 419mg / L CaCl 2 , 324.6mg / L MgCl 2 , 36.98mg / LNa 2 SO 4 , 84.8mg / L Na 2 CO 3 , 769.8mg / L NaHCO 3 and the balance is water), stir until completely dissolved, then weigh 0.875g of AP-P4 dry powder and slowly add it to the above-mentioned simulated mineralized water containing tetramethylol glycoluril, stir until completely dissolved to obtain a composite oil displacement agent, wherein , the mass volume concentration of tetramethylol glycoluril is 50mg / L, and the mass volume concentration of AP-P4 is 1750mg / L.

[0025] The obtained composite oil displacement agent was sheared for 20 seconds with the first gear of the WARING agitator to simulate the state of the composite oil displacement agent after the surface injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com