Uniform dispersion method of graphite granules in QTi3.5-10 graphite semi-solid slurry

A semi-solid slurry, graphite particle technology, applied in chemical instruments and methods, stirring devices, mixers, etc., can solve the problems of shortening the uniform dispersion time and long uniform dispersion time of graphite particles, shortening the uniform dispersion time, promoting the Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

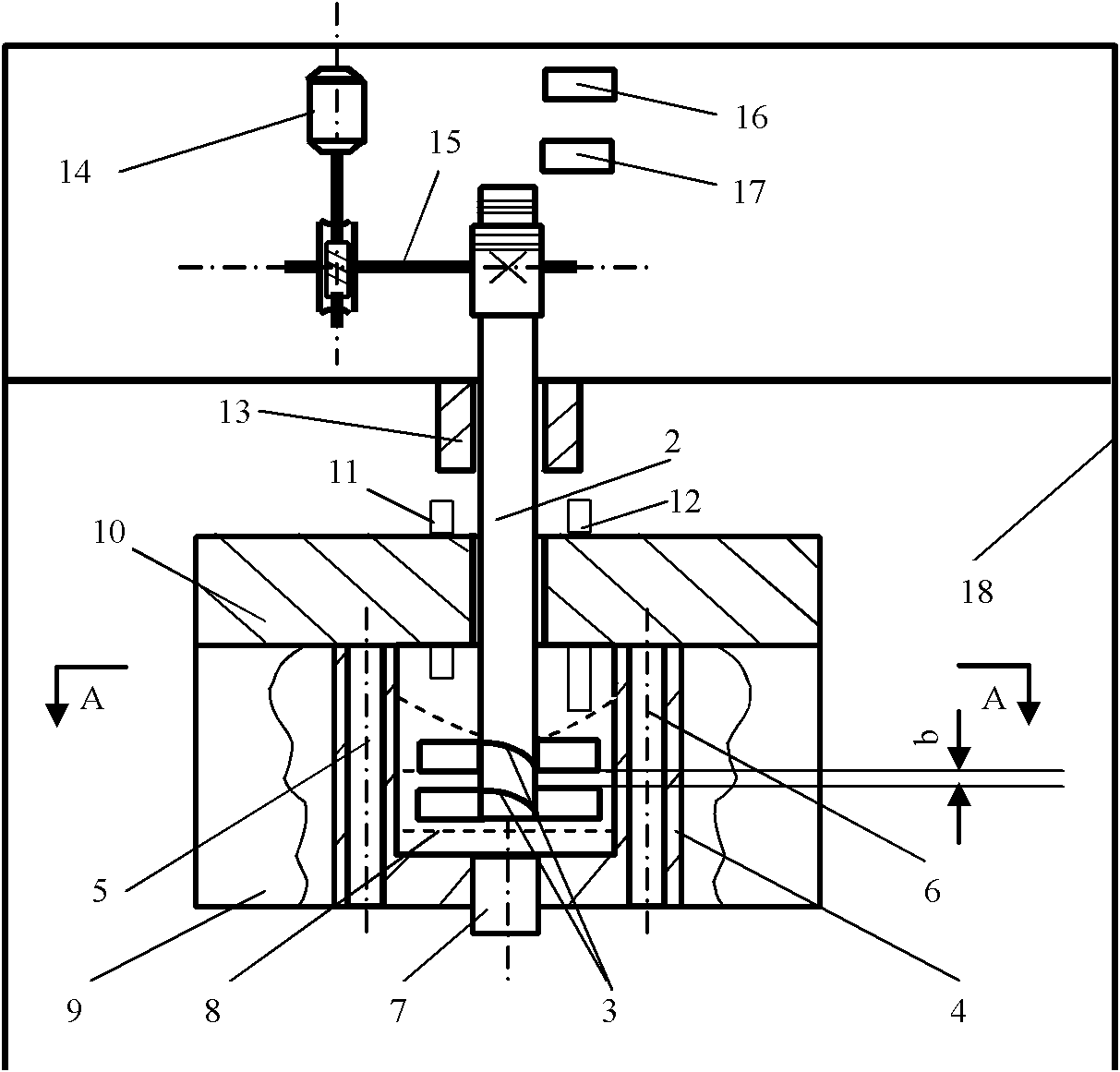

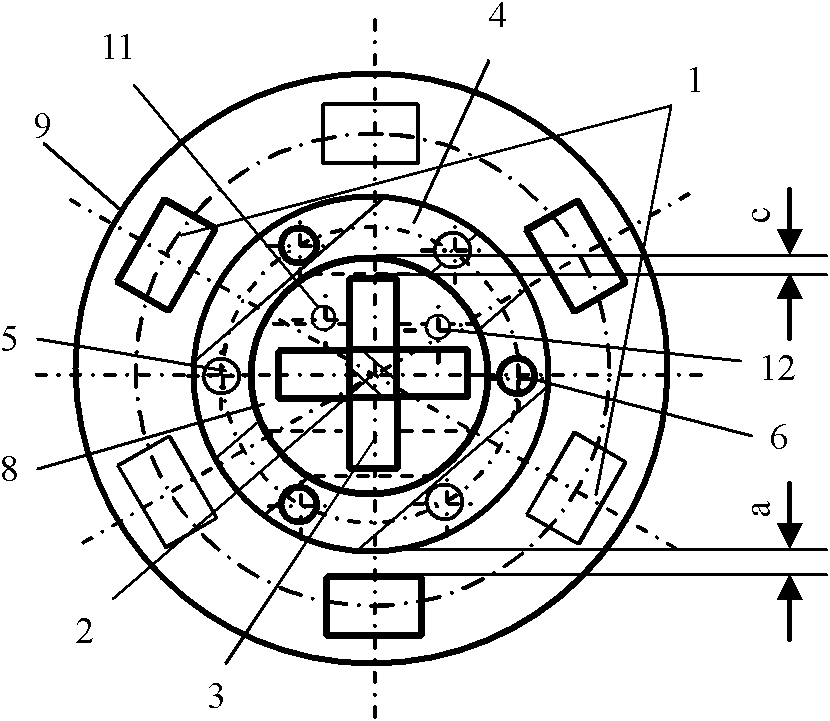

Method used

Image

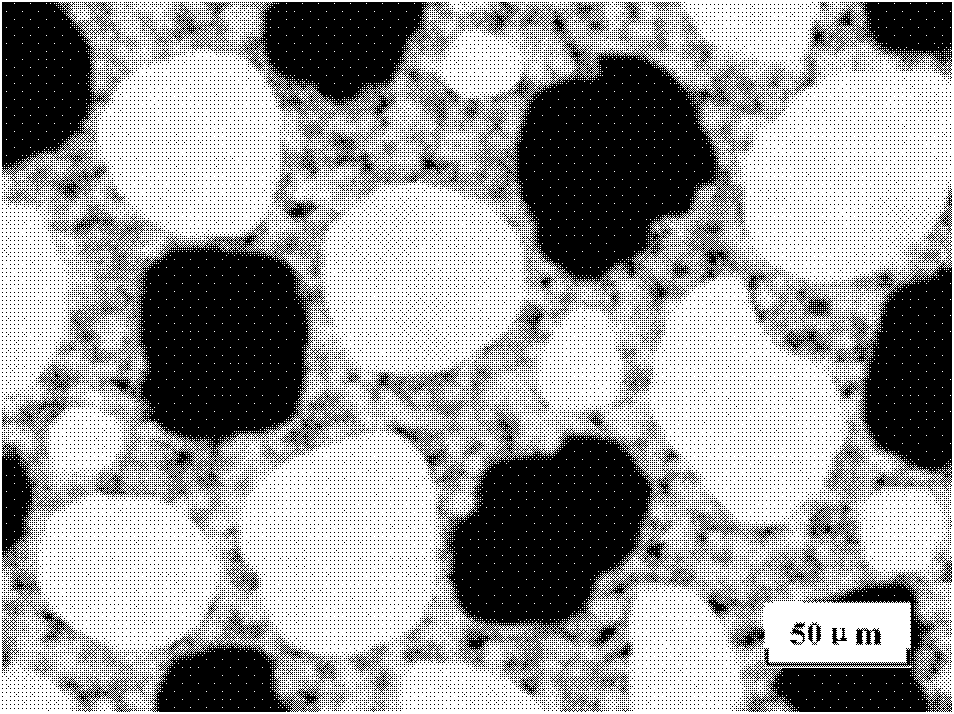

Examples

Embodiment approach 1

[0023] Embodiment 1, when the vertical movement speed of the mechanical disperser is 3mm / s, and the uniform dispersion temperature is 990°C, when the arc-shaped blades of the upper and lower layers of the double-bladed mechanical disperser have the radians of the concave arc surfaces of 59° and 79° respectively , the uniform dispersion time of QTi3.5-10 graphite semi-solid slurry to achieve uniform distribution of graphite particles is 8 minutes and 20 seconds.

Embodiment approach 2

[0024] Embodiment 2, when the vertical movement speed of the mechanical disperser is 1mm / s, and the uniform dispersion temperature is 990°C, when the arc-shaped blades of the upper and lower layers of the double-bladed mechanical disperser have a curvature of 59° and 81° respectively , the uniform dispersion time of QTi3.5-10 graphite semi-solid slurry to achieve uniform distribution of graphite particles is 8 minutes and 30 seconds.

Embodiment approach 3

[0025] Embodiment 3, when the vertical movement speed of the mechanical disperser is 10mm / s, and the uniform dispersion temperature is 1010°C, when the arc-shaped blades of the upper and lower layers of the double-blade mechanical disperser have the radians of the concave arc surfaces of 61° and 79° respectively , the uniform dispersion time of QTi3.5-10 graphite semi-solid slurry to achieve uniform distribution of graphite particles is 8 minutes and 30 seconds.

[0026] Embodiment 4, when the vertical movement speed of the mechanical disperser is 10mm / s, and the uniform dispersion temperature is 1010°C, when the arc-shaped blades of the upper and lower layers of the double-blade mechanical disperser have the radians of the concave arc surfaces of 61° and 81° respectively , the uniform dispersion time of QTi3.5-10 graphite semi-solid slurry to achieve uniform distribution of graphite particles is 8 minutes and 20 seconds.

[0027] Embodiment 5, when the vertical movement speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com