Single-well remote metering measurement and control method and device

A measurement and control method, measurement and control device technology, applied in the direction of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of inaccurate measurement of liquid level, inability to measure the water content of production fluid, large errors, etc., so that it is not easy to maintain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

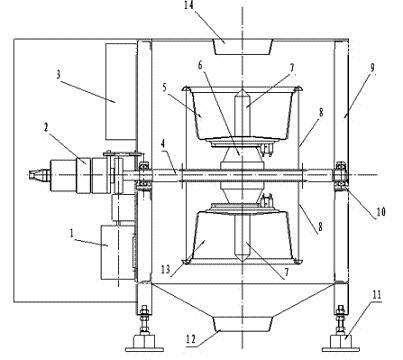

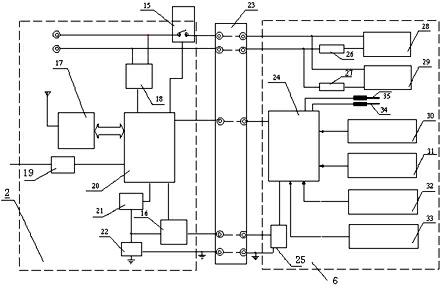

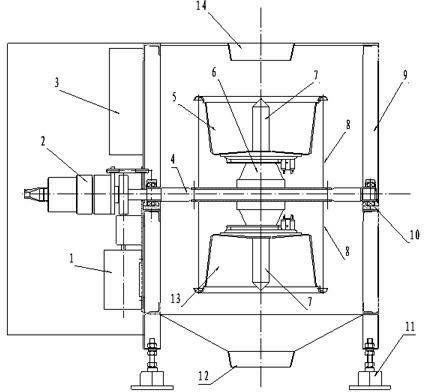

[0038] like figure 1 As shown, based on an embodiment device of the above-mentioned single well remote metering and control method, it at least includes: a container for measuring single well production liquid and an oil storage tank for storing single well production liquid, and the container is turned over The shaft 4 is fixed on the frame 9, and the turning shaft 4 is connected with the control mechanism 1 through a reducer. There is a capacitive oil-water measurement sensor 7 in the container, a weight and temperature control unit 6 at the bottom of the container, and the top of the container corresponds to the liquid production of a single well. Enter the upper end inlet 14 of the container, the bottom of the lower end of the container corresponds to the funnel 12, and the funnel 12 communicates with the oil storage tank; the output end of the control mechanism 1, the oil-water measurement sensor 7 and the output end of the weight and temperature control unit 6 are electri...

Embodiment 2

[0040]What is different from the embodiment is that the container may have a symmetrical structure formed by the first container 5 and the second container 13, the first container 5 and the second container are symmetrical with respect to the turning shaft 4, and the turning shaft 4 is connected to the left and right racks through the left and right bearings. 9 bearing connection, capacitive oil-water measuring sensor 7 is arranged in the first container 5 and the second container 13, weight and temperature control unit 6 are arranged at the bottom, the first container 5 and the second container 13 are sealed around by the casing. The working principle and process are as follows: single well production fluid flows into parts 5, 6 and 2 from the entrance of the upper end of the measuring instrument, and measures the weight of the inflowing production fluid, the water content of the production liquid, and the liquid temperature in part 5 in real time at fixed intervals. Part 2 ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com