Multi-channel mixed fuel burner

A mixed fuel combustion, multi-channel technology, applied in the direction of burners, lighting and heating equipment, etc., can solve problems such as conflicts and large coal consumption, and achieve the effects of reducing pollution, sufficient combustion, and avoiding high-temperature coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

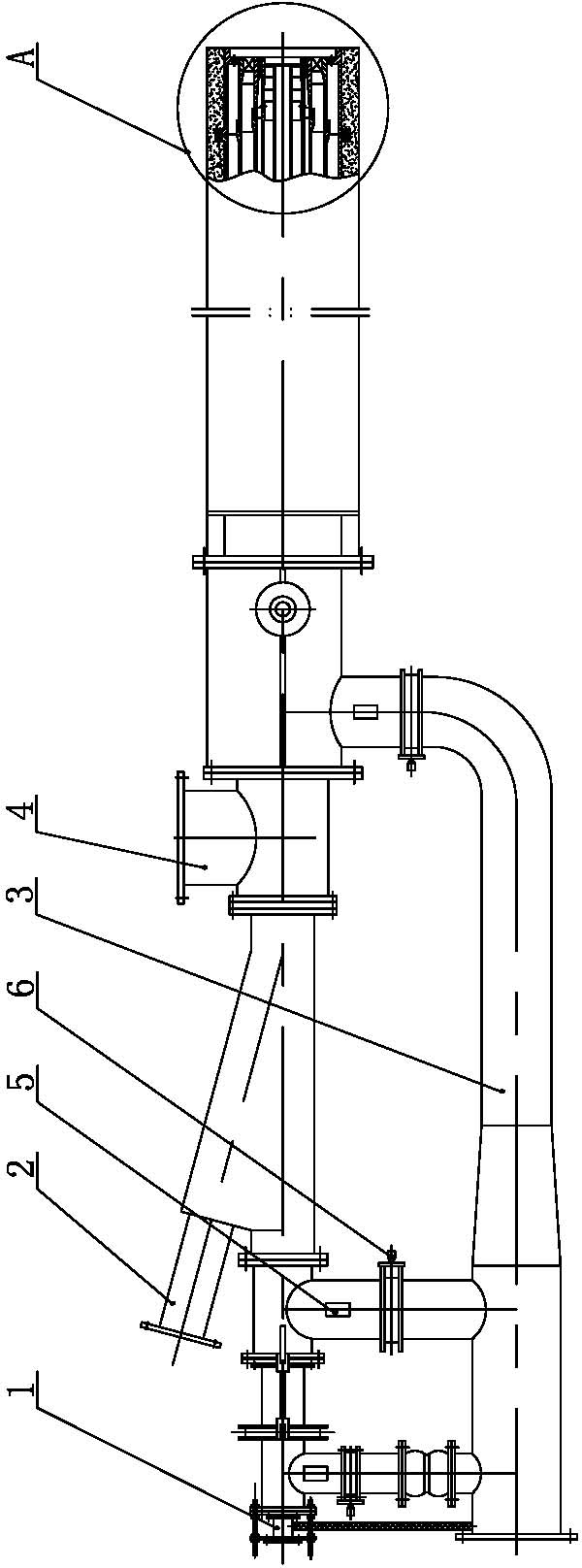

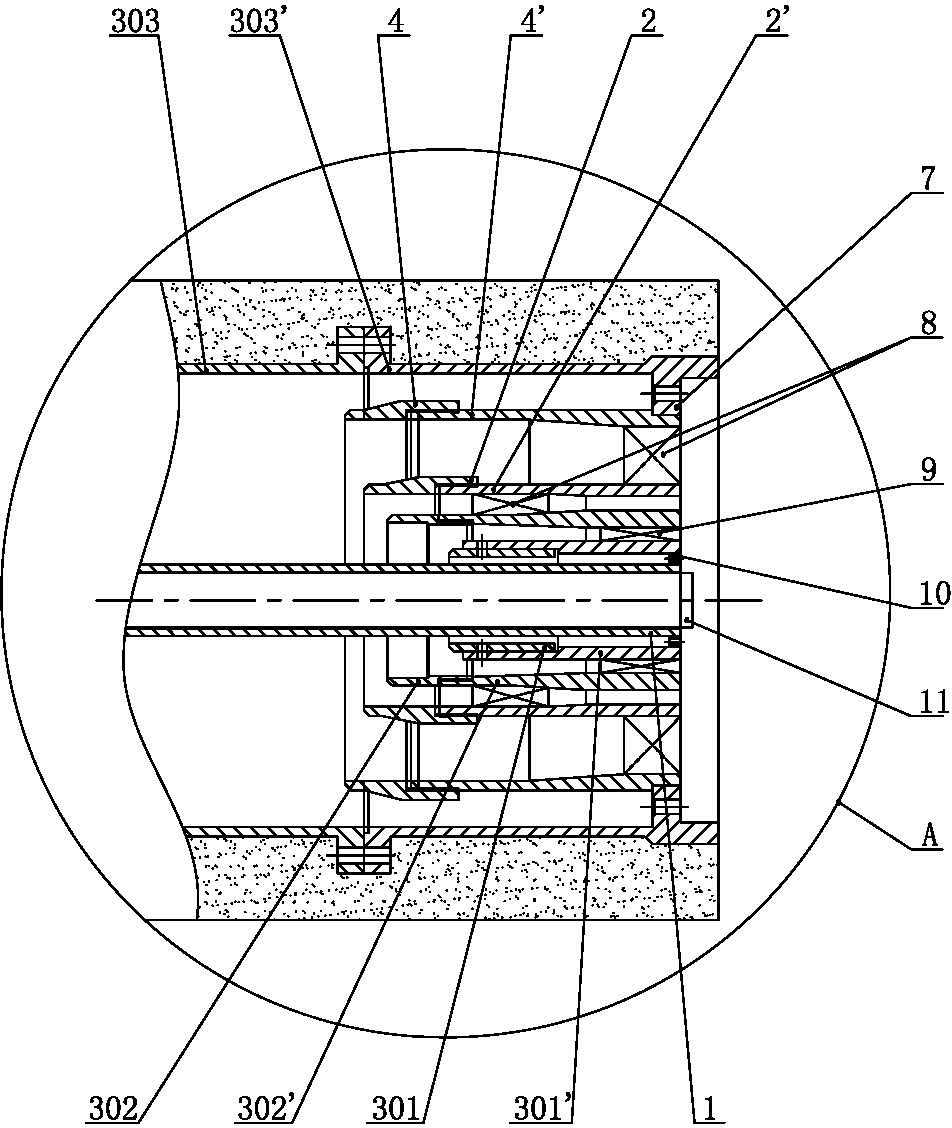

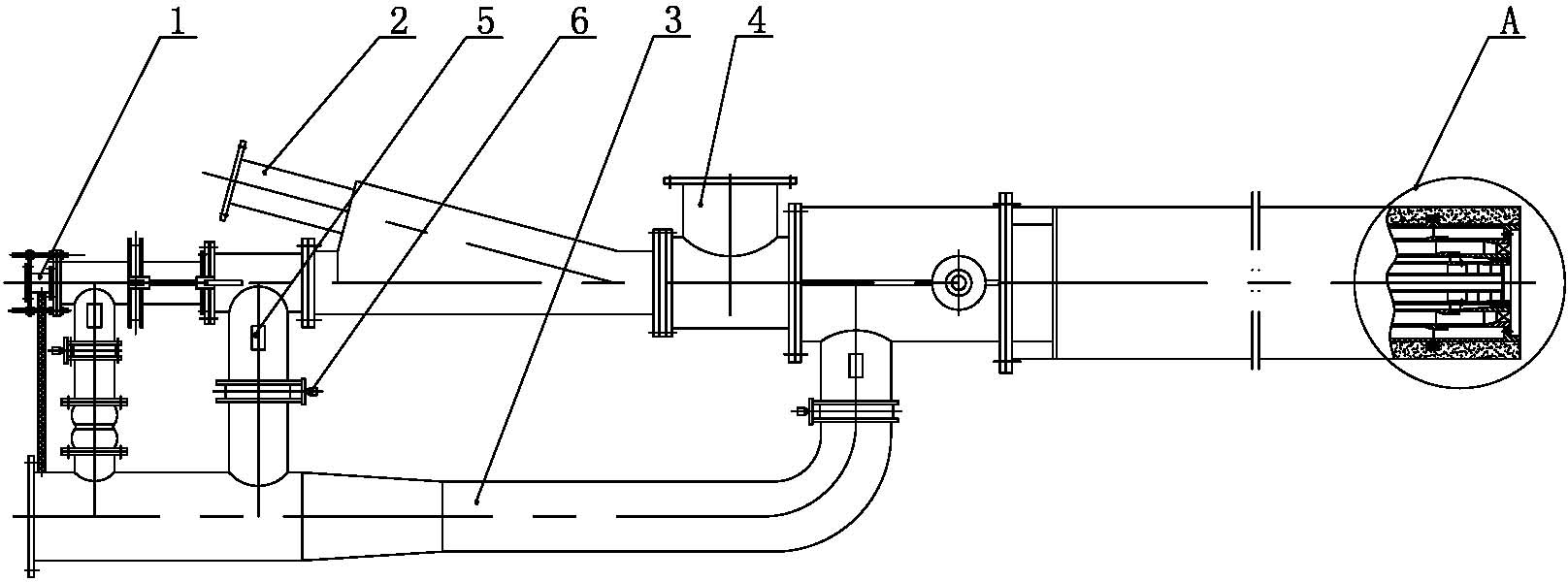

[0026] Such as figure 1 , 2, 3 shows a multi-channel mixed fuel burner, including an igniter channel pipe 1 and an inner air pipe 301, a cyclone pipe 302, and an air-coal pipe 2 coaxially sleeved outside the igniter channel pipe 1 from the inside to the outside. , natural gas pipe 4, external air pipe 303, the air outlet end of the internal air pipe 301 is connected with an internal air nozzle 301', and the outer circumference of the internal air nozzle 301' is sequentially set with a cyclone nozzle 302', an air coal nozzle 2', and a natural gas nozzle 4', the external wind nozzle 303', the cyclone nozzle 302' is connected to the air outlet end of the cyclone pipe 302, the air coal nozzle 2' is connected to the air outlet end of the air coal pipe, and the natural gas nozzle 4' is connected to the air outlet end of the natural gas pipe 4. The air nozzle 303' is connected to the air outlet end of the outer air pipe 303, the front end of the igniter channel pipe 1 protrudes from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com