Positioning device and method of coal mining machine in full-mechanized mining face

A fully-mechanized mining face and positioning device technology, which is applied in directions such as navigation through speed/acceleration measurement, can solve the problems of inability to meet the requirements of complex underground environments, inaccurate positioning, and inability to accurately determine the multi-directional position and attitude of the shearer , to achieve the effect of compact structure, high reliability and good positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

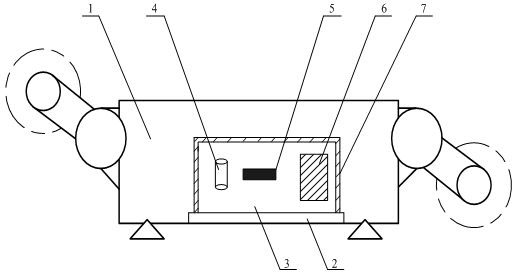

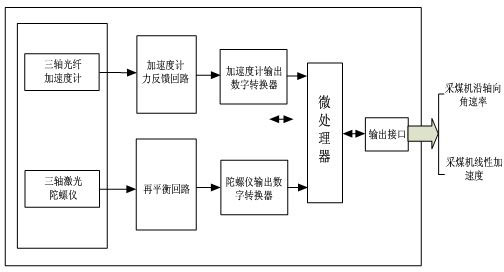

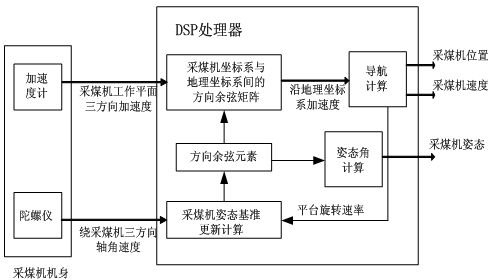

[0023] Embodiment 1: The shearer positioning device includes a fuselage 1, a rubber damping base 2, a shearer positioning device 3, a three-axis laser gyroscope 4, a three-axis optical fiber accelerometer 5, a positioning device micro-processing unit 6 and The explosion-proof shell 7 of the positioning device, the positioning device 3 of the coal mining machine is installed in the fuselage 1, and the positioning device 3 of the coal mining machine includes a rubber damping base 2, a three-axis laser gyroscope 4, a three-axis optical fiber accelerometer 5, and a positioning device micro The processing unit 6, the explosion-proof housing 7 of the positioning device, the explosion-proof housing 7 of the positioning device is connected above the rubber vibration-damping base 2, the three-axis laser gyroscope 4, the three-axis optical fiber accelerometer 5, and the micro-processing unit 6 of the positioning device are installed on the rubber The vibration-damping base 2 and the expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com