Ultrasonic nondestructive testing device and method

A non-destructive testing and testing device technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as missed detection and difficult identification, and achieve the effect of ensuring detection rate and subdivision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

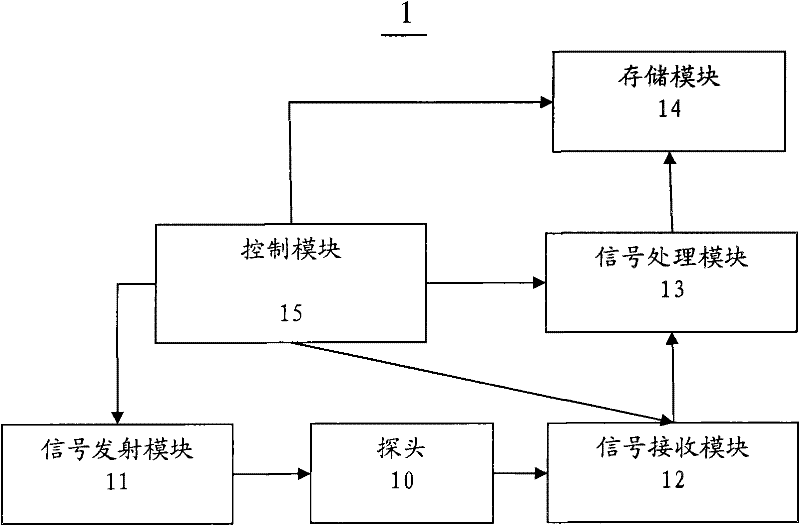

[0031] Such as figure 1 As shown, the present invention provides an ultrasonic nondestructive testing device 1, which can be especially applied to the detection of non-equal thickness test samples, wherein the non-equal thickness test samples are non-equal thickness laminates, more specifically, carbon fiber reinforced resin Composite laminates. The device 1 includes: a probe 10 , a signal transmitting module 11 , a signal receiving module 12 , a processing module 13 , a storage module 14 and a control module 15 . Wherein, the probe 10 is used for transmitting and receiving ultrasonic signals, and the probe 10 is essentially an electro-acoustic transducer, which utilizes the forward and reverse piezoelectric effects of the piezoelectric crystal sheet to work. The signal transmitting module 11 has a pulse generator, which is used to transmit electrical sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com