Chip bonding system and method

A chip bonding and chip technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems affecting the functions of substrates and chips, labor and time consumption, and increase production costs, so as to facilitate mass production , Simplify the process and stabilize the quality of chip bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

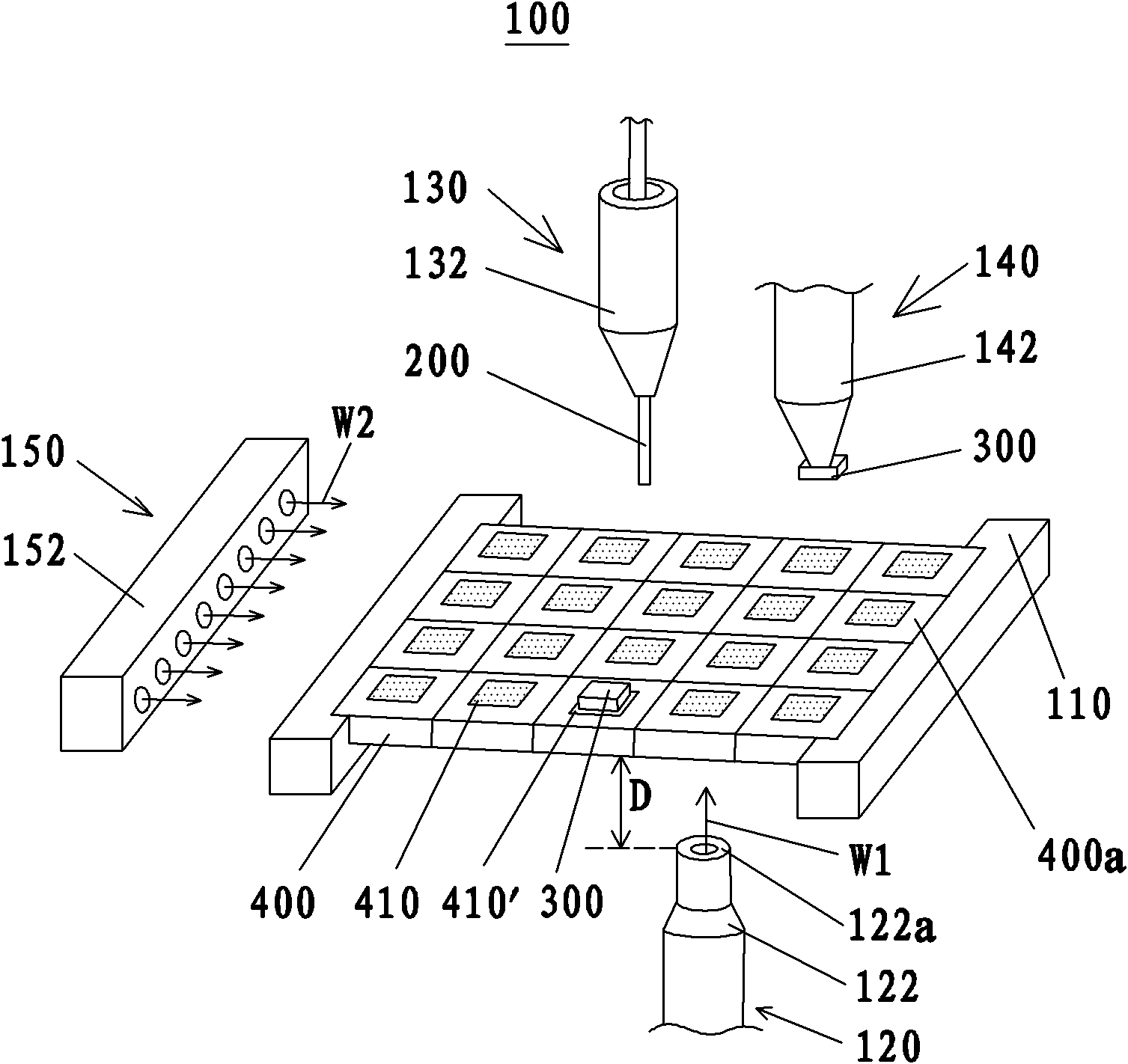

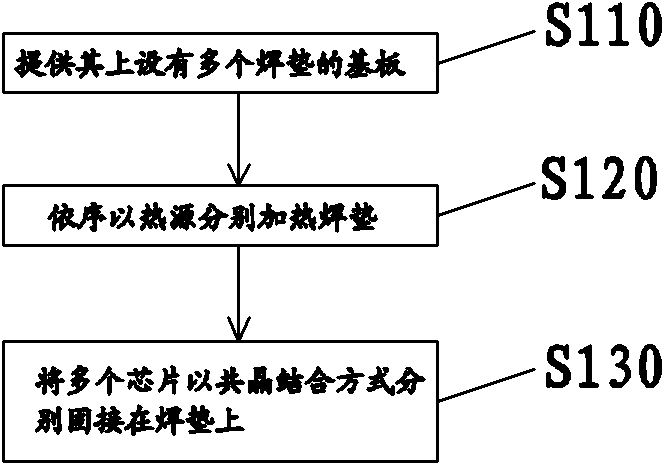

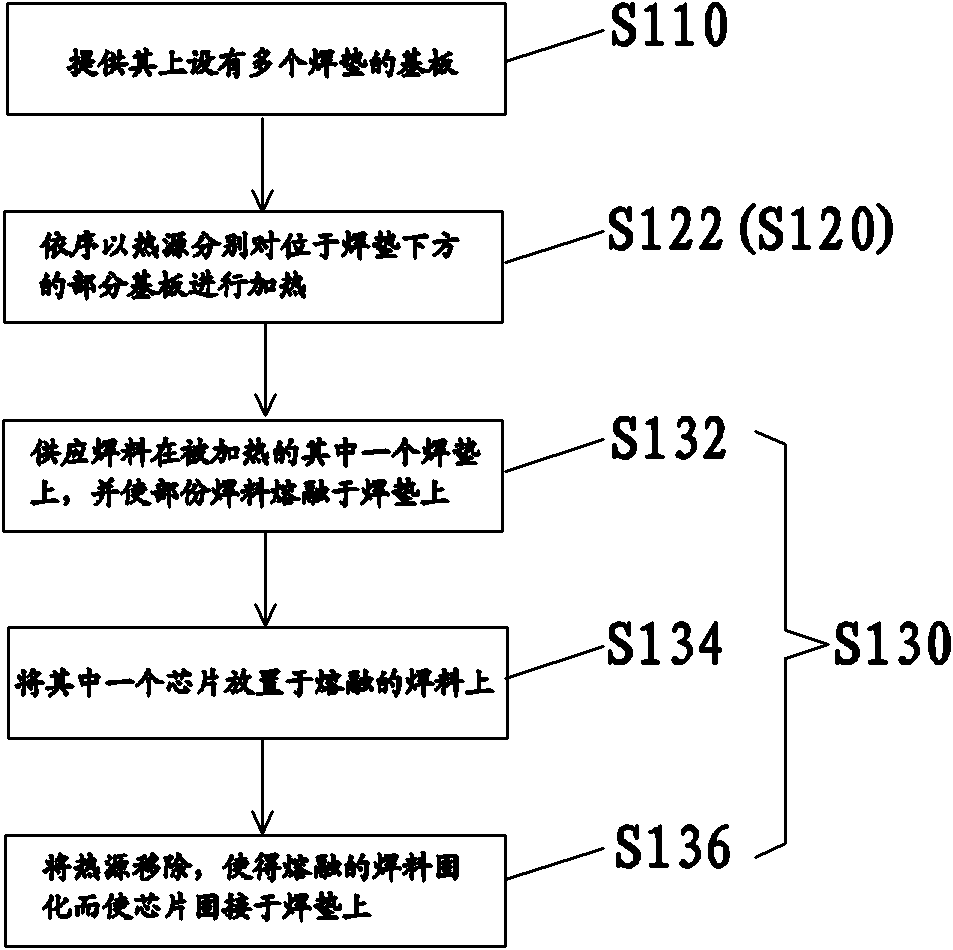

[0044] figure 1 It is a schematic diagram of a chip bonding system according to an embodiment of the present invention. Please refer to figure 1 , the chip bonding system 100 of this embodiment is suitable for fixing the plurality of chips 300 on the plurality of bonding pads 410 of the substrate 400 by using the solder 200 . The chip bonding system 100 of this embodiment includes a substrate positioning module 110 , a heating module 120 , a solder supply module 130 and a chip carrying module 140 . The substrate 400 may have a plurality of unit regions 400a, and one pad 410 is disposed on each unit region 400a. The solder 200 includes eutectic solder, and the material of the eutectic solder includes gold-tin alloy or silver-tin alloy.

[0045]The substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com