Light-emitting diode (LED) packaging method, packaging device and light adjusting method and system

A technology of LED packaging and LED chips, which is applied to electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of low light conversion rate, lack of light elements, and inability to adjust the brightness, color rendering and color temperature of LED packaging devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

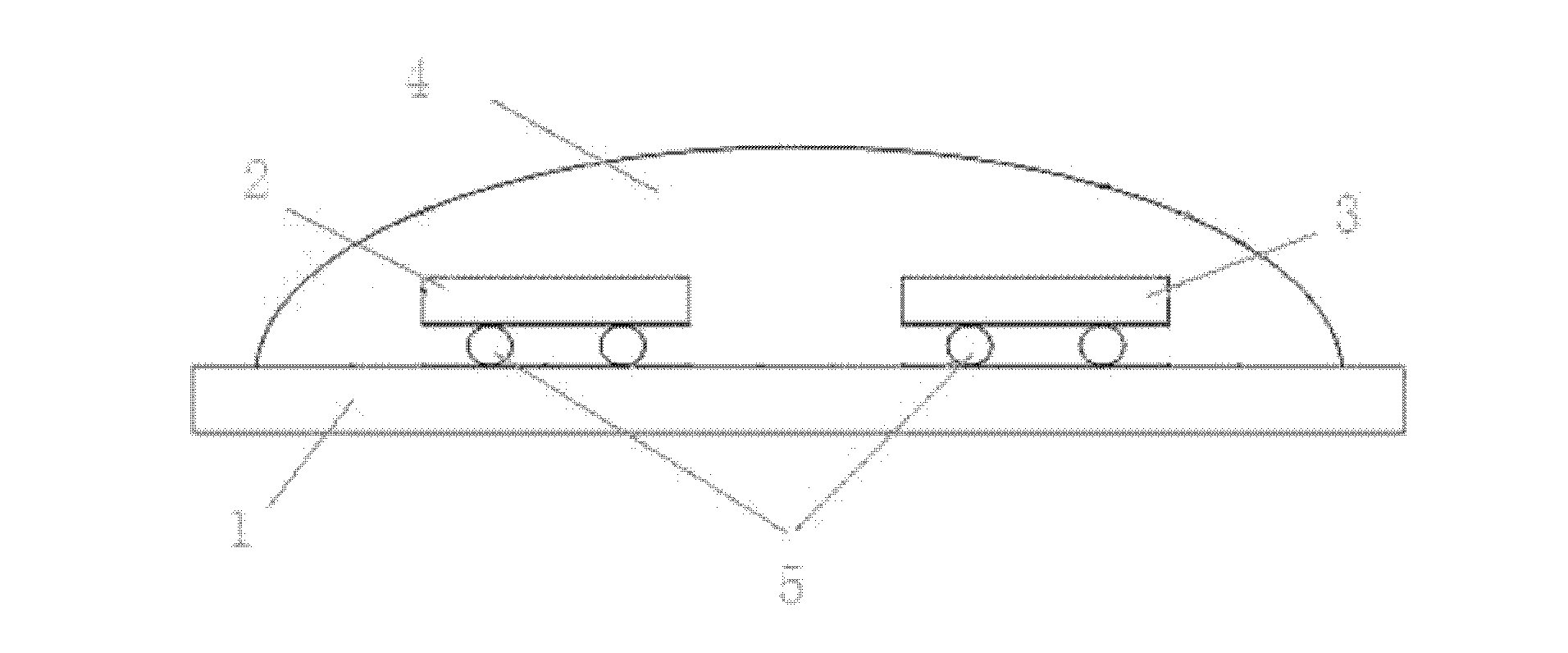

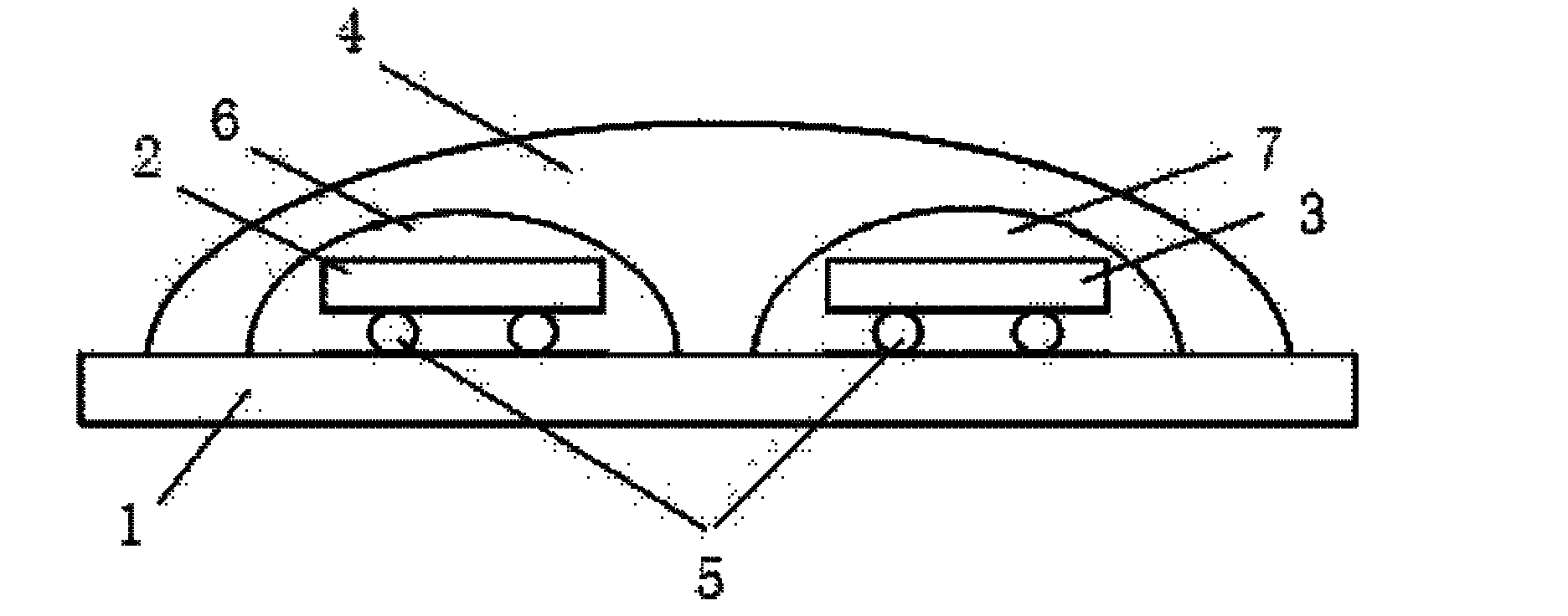

[0039] figure 1 For the schematic diagram of the LED packaging device of the embodiment of the present invention, please refer to figure 1 , it can be known that the LED packaging device of the embodiment of the present invention includes: a wafer 1 used as a substrate, an LED chip 2 and an LED chip 3 for generating different light emitting wavelengths when an electric current is applied, and the LED chip 2 and the LED chip 3 The lens layer 4 packaged in the same cavity is used to flip-chip the LED chip 2 and the LED chip 3 onto the flip-chip bump 5 of the wafer 1 .

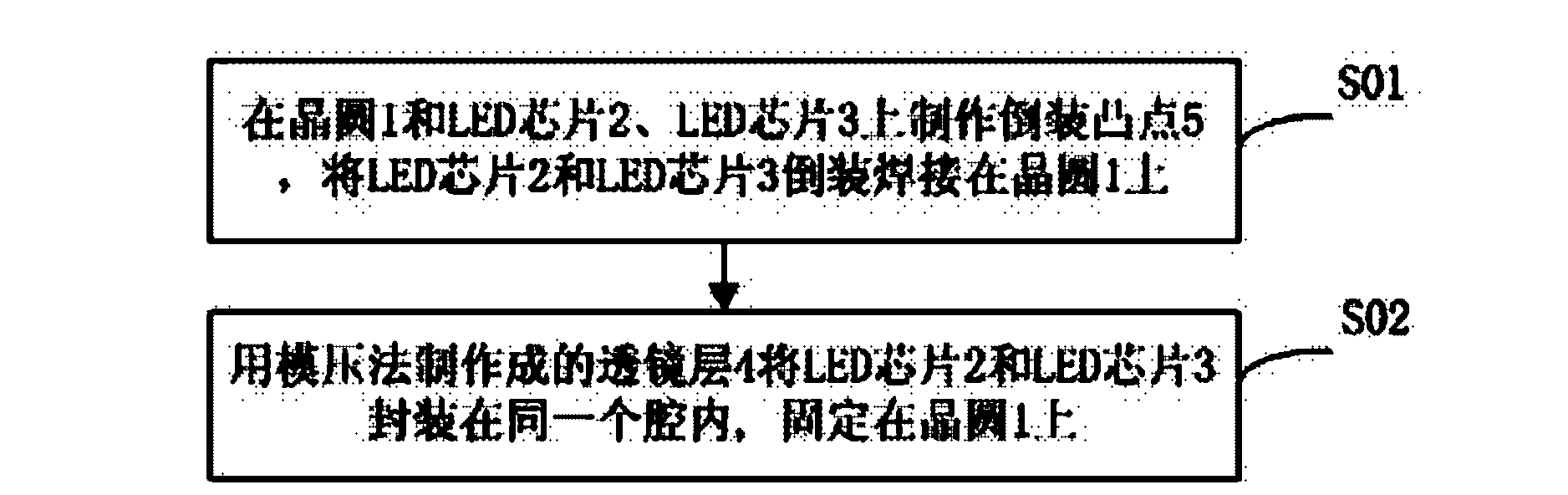

[0040] figure 2 For the flow chart of the LED packaging method in the embodiment of the present invention, please refer to figure 2 :

[0041] S01, making flip-chip bumps 5 on wafer 1, LED chip 2, and LED chip 3, and flip-chip welding LED chip 2 and LED chip 3 on wafer 1;

[0042] S02 , the lens layer 4 made by molding method encapsulates the LED chips 2 and the LED chips 3 in the same cavity, and fixes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com