Active cool type radiating substrate using air convection

A heat dissipation substrate and active heat dissipation technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems affecting life and performance, and achieve low cost, good heat dissipation effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

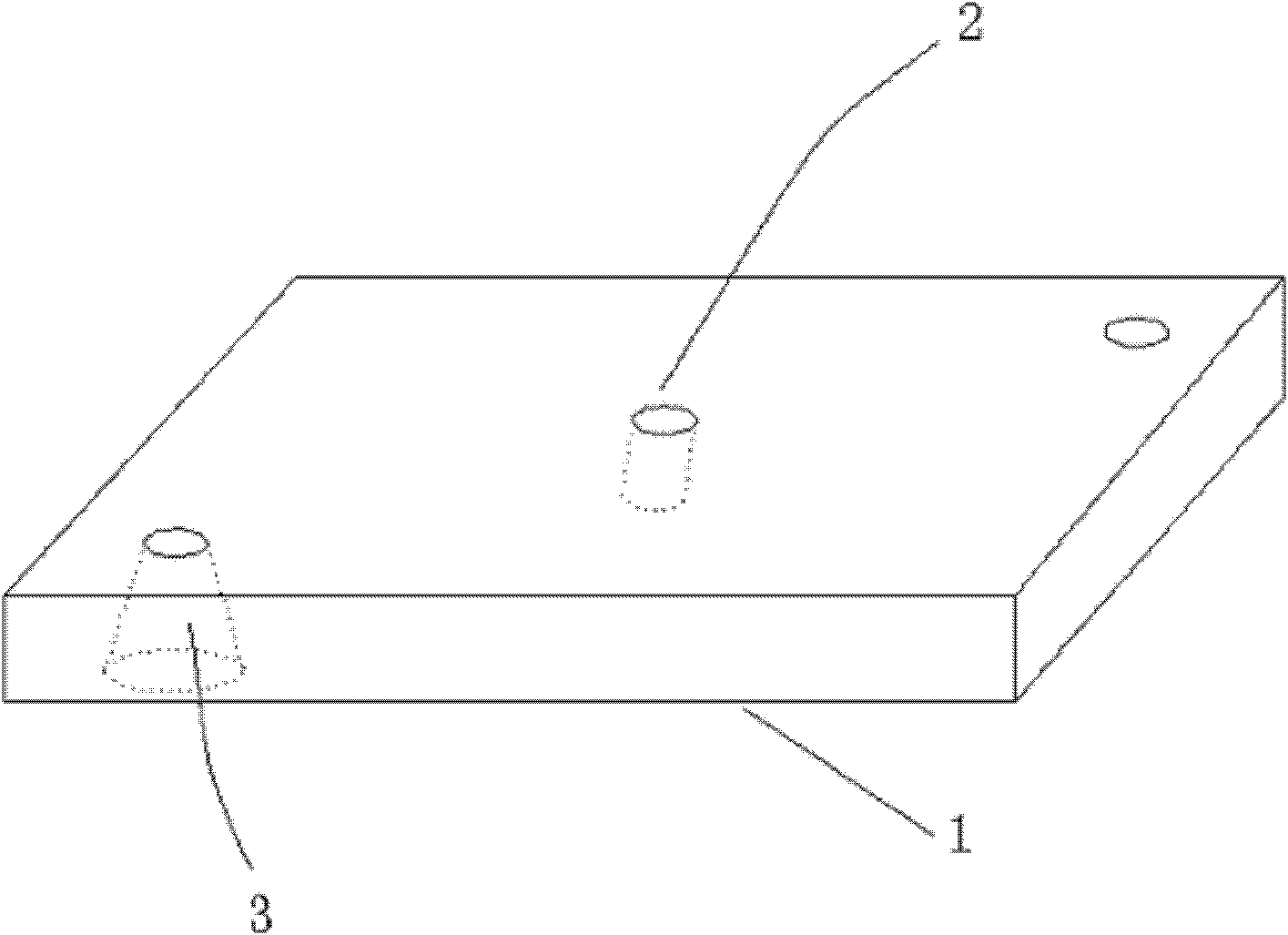

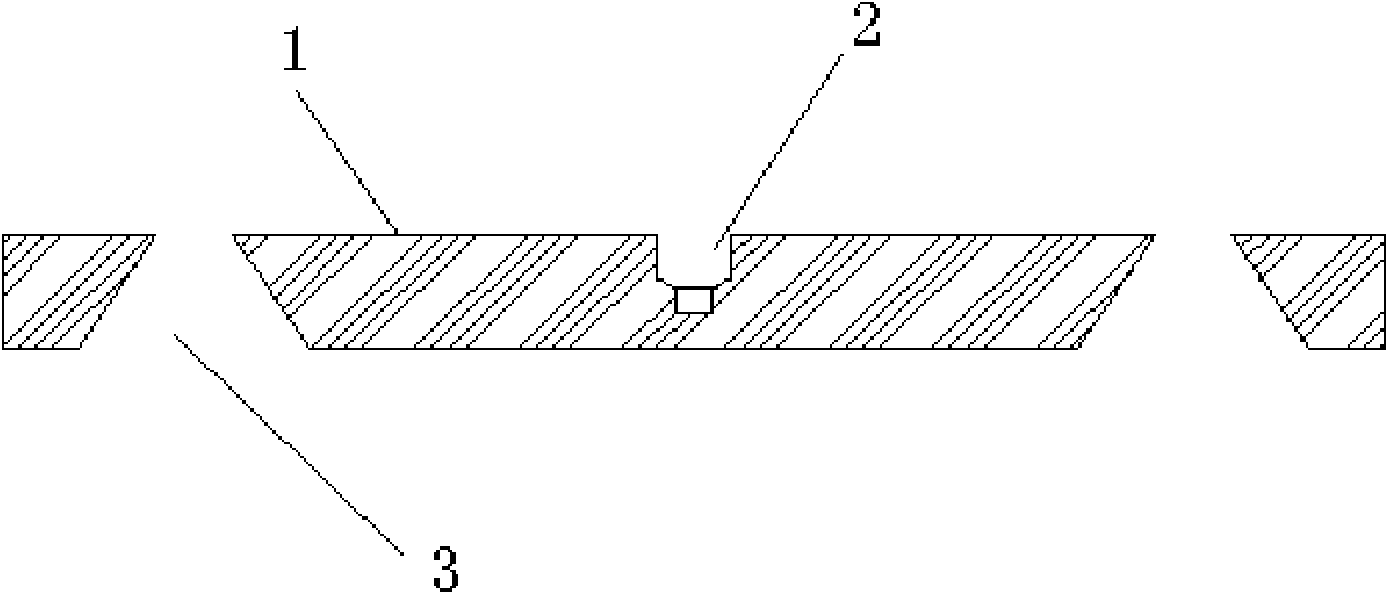

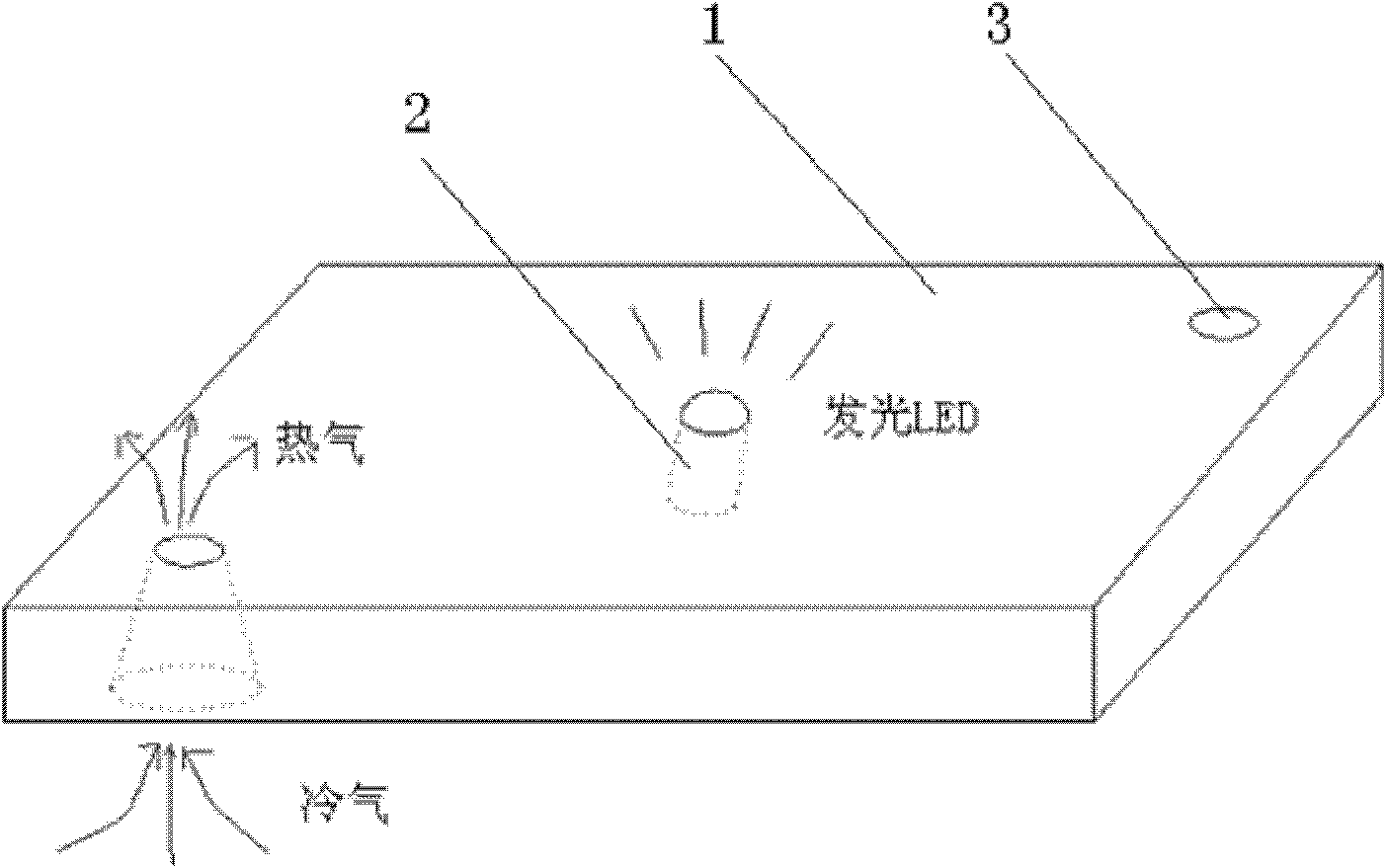

[0021] see figure 1 as well as figure 2 , including a heat dissipation substrate 1 connected to a heat dissipation device and a heat dissipation hole 3 arranged on the heat dissipation substrate 1, the heat dissipation hole 3 is conical, cylindrical or spiral, and the heat dissipation hole 3 is single or multiple, and the heat dissipation hole The inner wall of 3 and the outer surface of the heat dissipation substrate 1 are provided with textures, the textures are threads or twill, the heat dissipation substrate 1 is an aluminum substrate, a copper substrate, a silicon substrate, a ceramic substrate or a composite substrate, and the heat dissipation substrate 1 is a round shape, square or polygon, the heat dissipation substrate 1 is provided with a connection groove 2, the heat dissipation device is fixed on the connection groove 2, the connection groove 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com