Combined current transformer capable of realizing emergency regulation of output by series connection of high frequency AC sides

A high-frequency AC and converter technology, applied in the output power conversion device, the irreversible AC power input is converted into DC power output, and the DC power input is converted into DC power output, etc. The effect of improving efficiency, simple driving, and easy modularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

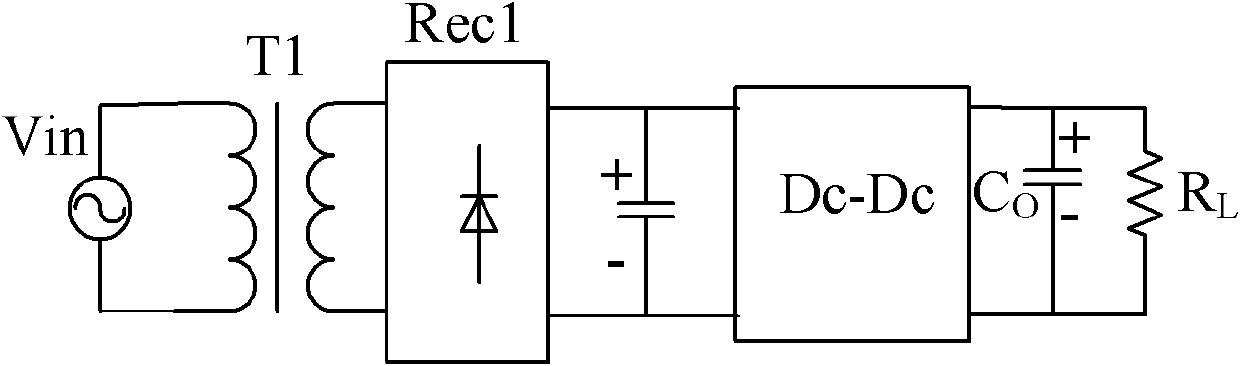

[0037] Embodiment 1 includes two transformers T1 and T2. After the primary winding of T1 is connected in series with the primary winding of T2, the other ends of each are respectively connected to the two ends of the AC input source Vin. The output of the secondary winding of T1 is connected to the input end of the rectification circuit Rec1. The output of the secondary winding of T2 is connected to the input end of the rectification circuit Rec2. One end of the output of the rectification circuit Rec1 is connected to the positive end of the capacitor Co, and the other end is connected to the negative end of the output Vo. One end of the load RL is connected to the positive end of the output capacitor Co, and the other end is connected to the negative end of the output Vo. One end of the output of the rectification circuit Rec2 is connected to the positive end of the capacitor C1, and the other end is connected to the negative end of C1. The positive end of C1 is connected t...

Embodiment 2

[0039] In order to further reduce the current ripple on the output side and reduce the current stress of the output capacitor, a filter inductor can be added on the output side of the rectifier circuit REC1, such as Figure 5 shown.

[0040] In the combined converter, there are two transformers T1 and T2. After the primary winding of T1 is connected in series with the primary winding of T2, the other ends of each are respectively connected to the two ends of the AC input source Vin. The output of the secondary winding of T1 is connected to the input end of the rectification circuit Rec1. The output of the secondary winding of T2 is connected to the input end of the rectification circuit Rec2. One end of the output of Rec1 is connected to one end of the output inductor Lo, and the other end of C is connected to the negative end of the output Vo. The other end of the inductor Lo is connected to the positive end of the output capacitor. One end of the load RL is connected to t...

Embodiment 3

[0042] Putting the filter inductor on the output side of Rec2 can also reduce the current ripple, such as Image 6 shown.

[0043]In the combined converter, there are two transformers T1 and T2. After the primary winding of T1 is connected in series with the primary winding of T2, the other ends of each are respectively connected to the two ends of the AC input source Vin. The output of the secondary winding of T1 is connected to the input end of the rectification circuit Rec1. The output of the secondary winding of T2 is connected to the input end of the rectification circuit Rec2. One end of the output of Rec1 is connected to the positive end of Co, and the other end is connected to the negative end of the output Vo. One end of the load RL is connected to the positive end of the output capacitor Co, and the other end is connected to the negative end of Vo. One end of the output of the rectifier Rec2 is connected to one end of the inductor L1, and the other end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com