Fishing pole

A fishing rod and rod body technology, applied in fishing rods, fishing, applications, etc., can solve problems such as stress concentration, loss of rigid continuity, strength problems, etc., and achieve the effect of alleviating stress concentration, easy production, and soft bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

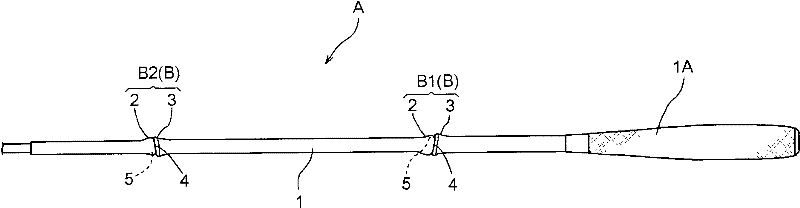

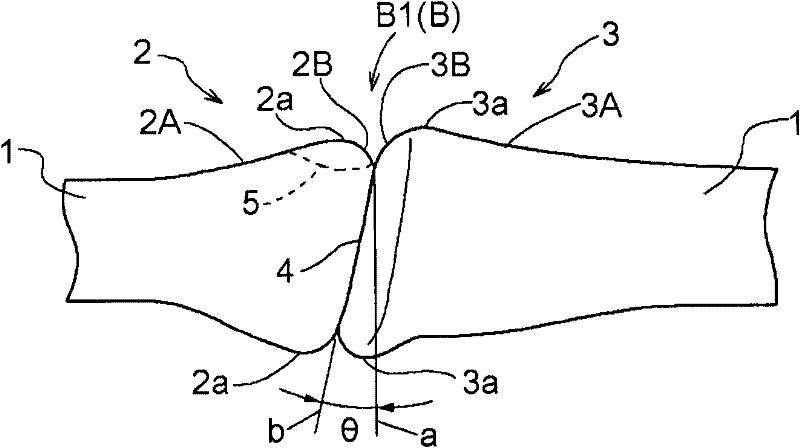

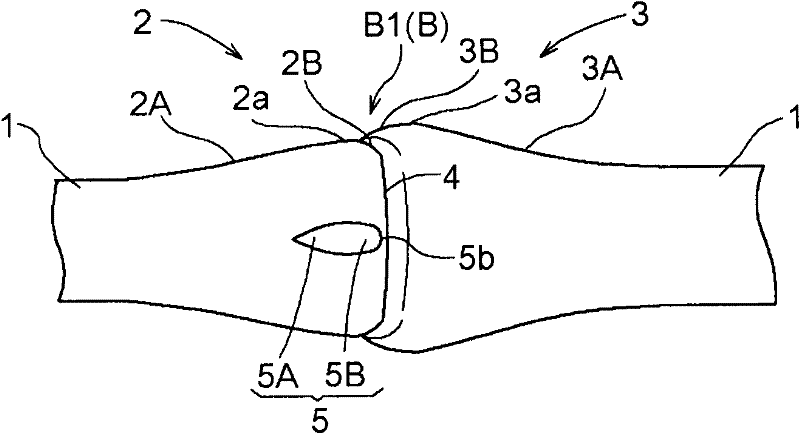

[0063] Such as figure 1 and Figure 4As shown, the fishing rod A is a rod used for fishing Japanese crucian carp. It has a grip part 1A on the tail rod 1 as the rod body. Slubs B are formed at two places on the rod tip side of the grip part 1A, and are bulged through the rod tip side. The bulging part 2 and the butt-side bulging part 3 form a slub B, thereby constituting a fishing rod A.

[0064] In addition, each rod body which comprises the fishing rod A was produced as follows. That is, reinforcing fibers such as carbon fibers are aligned in one direction, and a thermosetting resin such as epoxy resin (or thermoplastic resin) is impregnated into the aligned reinforcing fiber groups to form a prepreg sheet. The prepreg sheet is cut into a predetermined shape and wound on a mandrel, and the above-mentioned multi-layered structure is placed in a furnace in the state wound on the mandrel and sintered. After sintering, the mandrel is The core is removed and the cylindrical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com